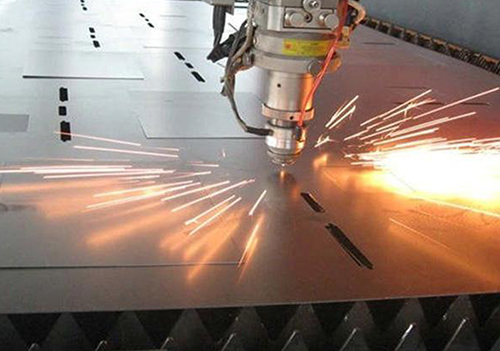

Compared with other thermal cutting methods, laser cutting is characterized by high cutting speed and high quality. It can be summarized as follows.

(1) Good cutting quality

Because the laser light spot is small, the energy density is high, and the cutting speed is fast, the laser cutting can achieve better cutting quality.

① Laser cutting is narrow, with both sides of the incision parallel and perpendicular to the surface, and the dimensional accuracy of the cut parts can reach 0.05mm.

The cutting surface is smooth and beautiful, with a surface roughness of only a few tens of microns. Even laser cutting can be used as a final process without machining, and parts can be directly used.

③ After the data is laser cut, the width of the heat-affected zone is very small, and the performance of the materials adjacent to the slit is almost unaffected. Moreover, the deformation of the workpiece is small, the cutting accuracy is high, the shape of the slit is good, and the cross-sectional shape of the slit is relatively regular. The comparison of laser cutting, oxyacetylene cutting and plasma cutting methods is shown in Table 1. The cutting data is a low-carbon steel plate with a thickness of 6.2mm.

(2) High cutting efficiency Because of the transmission characteristics of the laser, the laser cutting machine is equipped with multiple CNC worktables, and the entire cutting process can be fully realized by numerical control. During operation, only need to change the numerical control program to apply the cutting of parts of different shapes, which can be used for both two-dimensional cutting and three-dimensional cutting.

(3) Fast cutting speed

With 1200W laser cutting 2mm thick low carbon steel plate, the cutting speed can reach 600cm/min; cutting 5mm thick polypropylene resin plate, the cutting speed can reach 1200cm/min. The data does not need to be clamped and fixed when laser cutting, which can save the tooling fixture and the auxiliary time of loading and unloading.

(4) Non-contact cutting

When laser cutting, the cutting torch has no contact with the workpiece, and there is no wear and tear. To process parts of different shapes, there is no need to replace the "tool", just change the output parameters of the laser. The laser cutting process has low noise, small oscillation, and no pollution.

(5) There are many varieties of cutting materials

Compared with oxyacetylene incision and plasma incision, there are many types of laser incision materials, including metal, non-metal, metal-based and non-metal-based composite materials, leather, wood and fiber. However, different materials exhibit different laser incision adaptability due to their different thermophysical properties and laser absorption rates. CO2 lasers are used, and the laser incision performance of various materials is shown in Table 2.

Due to the limitations of laser power and equipment volume, laser cutting can only cut medium and small thickness plates and pipes, and with the increase of workpiece thickness, the cutting speed decreases significantly.

Laser cutting equipment is expensive and requires a large one-time investment.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque