Aluminum profile materials are lightweight, beautiful, breathable and other characteristics, as well as good mechanical properties and processing properties, so they are widely used in various fields. As a material for making cabinets, aluminum profiles are used by more and more manufacturers due to their high strength, good credit, light weight and beautiful appearance. The following is an introduction to the process flow of Sheet Metal Processing for aluminum profile cabinets. Chassis cabinet sheet metal processing

Material preparation

Material preparation

The production of aluminum cabinets requires the selection of aluminum profiles with moderate thickness and flat surface as the material. Before processing, the material needs to be cut, polished, cleaned and other preparations.

CAD design

In the design process of aluminum cabinet, the use of CAD software is essential. Designers need to draw accurate drawings according to customer needs, and ensure that the size, shape, fit clearance, etc. of the design meet the requirements. At the same time, determine the required materials and processes according to the design drawings.

III. Cutting

Cutting is an important step in the processing of aluminum profile cabinets. There are two kinds of cutting methods: manual cutting and mechanical cutting. Manual cutting is easy to operate, low cost, but low precision. Mechanical cutting uses numerical control cutting machines, which have high cutting accuracy and can complete highly standardized production.

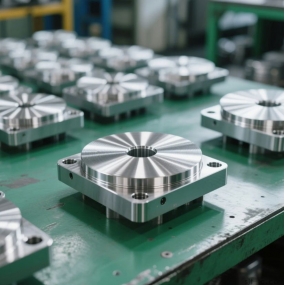

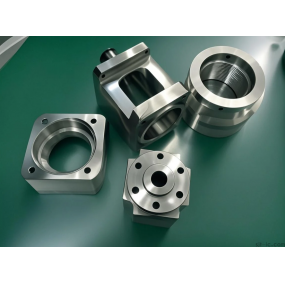

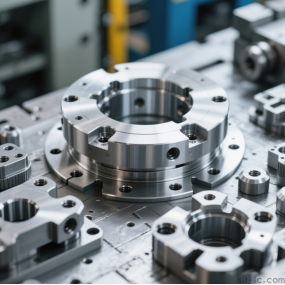

Forming

Forming is a key step in the processing of aluminum profile cabinets. It is formed by machines such as punching machines and bending machines. These machines can bend, fold, and press aluminum profiles to form formed parts.

Five, splicing

Splicing is an important step to combine parts together as required to form an aluminum profile cabinet. Commonly used splicing methods include riveting, welding, screw connection, etc.

Spraying

Spraying is the last process of ZUI for aluminum profile cabinets, mainly to enhance the aesthetics and corrosion resistance of the surface. After the aluminum profile cabinet is made, it needs to be cleaned, polished and other treatments on its surface before painting.

In summary, the process of sheet metal processing of aluminum profile cabinets is a complex process that requires the cooperation of various machines in order to successfully produce high-quality aluminum profile cabinets.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque