Sheet Metal Processing is a key field in the manufacturing industry, involving many aspects, including material selection, cutting, bending, punching, etc. EMAR cabinet is a well-known brand, it has high-quality sheet metal product manufacturing, for other companies, can learn from the experience of EMAR cabinet. The sheet metal processing company will discuss the main points of sheet metal processing of imitation EMAR cabinet from the aspects of material selection, production process, etc.

First, material selection

First, material selection

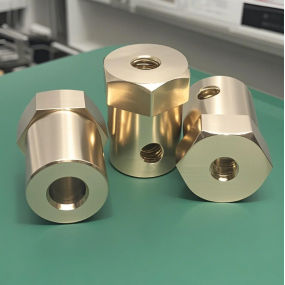

Material selection is one of the key links in sheet metal processing, and the processing process varies depending on the material. First of all, the materials used in EMAR cabinets are cold-rolled galvanized sheet and stainless steel sheet with certain bending strength. These materials have high strength and hardness, as well as good corrosion resistance and surface gloss.

Process flow

Step 1 Cut

When processing sheet metal products, the material should be cut into the corresponding size and shape according to the requirements of the drawings. Cutting is the first step in sheet metal processing, and a shearing machine is generally selected for cutting. Before cutting, check the size, adjust the parameters of the shearing machine, and then start cutting.

Step 2 Bend

Bending is an important process link in sheet metal processing of imitation EMAR cabinets, and the sheet metal needs to be folded into the corresponding shape according to the requirements of the product. Bending requires the use of a bending machine, usually using bakelite for positioning and iron plate fixing, and then bending the sheet metal up and down into a certain angle according to the requirements of the drawings. At the same time, when bending, it is necessary to ensure that the surface of the plate is not damaged. After bending, the size after bending should be checked to ensure that it meets the requirements.

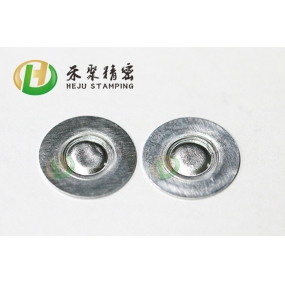

3. Punching

Punching is a process required for positioning or connection in sheet metal processing. The holes in EMAR cabinet sheet metal products are generally cut by a laser cutting machine. When punching, it is necessary to locate first, and take certain anti-shake measures to avoid sheet metal shaking during cutting to avoid cutting mistakes.

Step 4: Welding

In the processing of sheet metal products, welding is often required to connect sheet metal parts. There are many welding methods, commonly used are argon arc welding, manual welding and CO2 welding. Before welding, the joint surface should be treated and suitable welding parameters should be used for welding. In addition, during the welding process, attention should be paid to keeping the welding area clean to prevent oxygen, moisture, etc. from accelerating the rust of the sheet metal.

III. Equipment requirements

Sheet metal processing requires the use of machinery and equipment. EMAR cabinet sheet metal processing mainly uses main equipment such as shears, bending machines, punches, and laser cutting machines. The equipment requirements are that the equipment has stable performance and high precision, which can meet the requirements of accuracy during high-speed operation. In the production process, the equipment requirements must be well maintained, and regular maintenance is carried out. At the same time, the safety of the equipment is also very important, and regular safety inspections are required.

IV. Requirements for personnel quality

When performing sheet metal processing of imitation EMAR cabinets, the quality of personnel is also very important. Processing personnel need to have a high professional level and sheet metal processing experience. At the same time, they also need to strictly check the surface quality such as light color, luminosity, and gloss to ensure that the quality of the produced sheet metal products meets the requirements. In addition, attention should be paid to the safety of personnel during processing to prevent accidents during sheet metal processing.

V. Quality Control

In the processing process, EMAR cabinet sheet metal processing company pays attention to product quality control, not only needs to conduct quality inspection in each process link, but also needs to conduct a full inspection of sheet metal products after processing to ensure that the product quality meets the standards.

The above content is the main points of sheet metal processing for imitation EMAR cabinets. It is important to pay attention to material selection, process flow, equipment/personnel quality and quality control to ensure the quality of sheet metal processing. Only on the basis of comprehensive mastery of the above knowledge can we achieve products similar to EMAR cabinets.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque