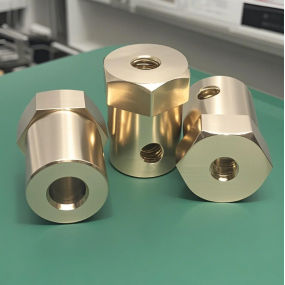

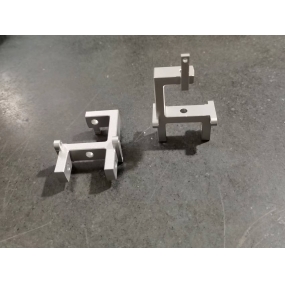

Micro parts processing is a high-precision and high-efficiency processing method, which usually requires the use of high-precision equipment, such as high-speed spindle, high-magnification telecentric lens camera, etc. This processing method is widely used in medical, aviation, optics, automobiles, semiconductors, universities and other fields.  The core equipment of micro parts processing includes high-speed spindle, high-magnification telecentric lens camera and linear motor. The accuracy of high-speed spindle has a great impact on the processing results. The maximum speed can reach 60,000rpm and the accuracy is 1 μm. The high-magnification telecentric lens camera has the function of calibrating the tool center and camera center error. At the same time, it can be used to detect the workpiece size online and determine the margin for micro-nano machining. The linear motor has the characteristics of high precision and high response, which can realize micro-grinding The software for micro-part processing is also very important. It needs to have CNC function, which can edit the instructions of different shapes to automatically complete the part processing needs. In addition, the software should also have custom motion trajectory control function, edit different shapes, and automatically complete the part processing needs. In short, the processing of micro-parts requires the use of high-precision equipment and technology to achieve high-precision and high-efficiency machining results.

The core equipment of micro parts processing includes high-speed spindle, high-magnification telecentric lens camera and linear motor. The accuracy of high-speed spindle has a great impact on the processing results. The maximum speed can reach 60,000rpm and the accuracy is 1 μm. The high-magnification telecentric lens camera has the function of calibrating the tool center and camera center error. At the same time, it can be used to detect the workpiece size online and determine the margin for micro-nano machining. The linear motor has the characteristics of high precision and high response, which can realize micro-grinding The software for micro-part processing is also very important. It needs to have CNC function, which can edit the instructions of different shapes to automatically complete the part processing needs. In addition, the software should also have custom motion trajectory control function, edit different shapes, and automatically complete the part processing needs. In short, the processing of micro-parts requires the use of high-precision equipment and technology to achieve high-precision and high-efficiency machining results.

안녕하세요!EMAR 회사 웹 사이트에 오신 것을 환영합니다!

Korean

Korean » »

» »

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque