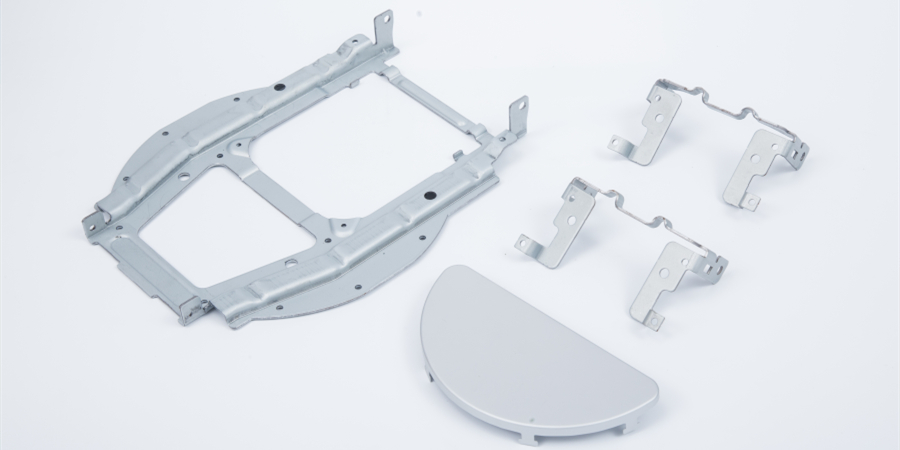

In actual production, Metal Stamping parts often present various shortcomings: wrinkling, stacking, neck shrinkage, springback, uneven trimming, burrs, crushing, and slip lines. Part stacking shortcomings can cause parts to be scrapped. Product feature planning in the stacking area causes simple accumulation of materials during stamping. Once the material activity is not smooth, there will be stacking problems.

Plate stacking due to the die blank holder force is too small, the drawing process of the sheet material activity is too fast, the size of the sheet is too short and other factors that cause the stacking material not only affect the quality of the metal stamping parts, but also bring restrictions to the production and processing. At the same time, it causes certain damage to the mold, reducing the service life of the mold. Therefore, it is necessary to analyze the cause of the stacking material, and then deal with it in detail.

1. The machine tool master cylinder and blank holder force are not good, the forming pressure is too low, and the CAE reference pressure value is not reached. It is necessary to adjust the forming pressure treatment;

2. The size of the sheet is too short, the material activity is too fast during molding, and the drawing rib does not have an effect. The treatment method needs to increase the size of the material;  3. The pressing surface is not in place, the inner ring is too loose, and the outer ring is too tight. It is necessary to re-ground the pressing surface to make the inner ring of the pressing surface compacted, and the surface is re-ground to improve the research rate.

3. The pressing surface is not in place, the inner ring is too loose, and the outer ring is too tight. It is necessary to re-ground the pressing surface to make the inner ring of the pressing surface compacted, and the surface is re-ground to improve the research rate.

4. The height of the drawing rib is too low, and the drawing rib cannot be effective during the sheet metal forming process, resulting in too fast material activity. It is necessary to repair welding and increase the drawing rib for debugging;

5. The process design is unreasonable, there is a trend of stacking in the process of CAE theoretical analysis, and no measures are taken, resulting in severe production of stacking, and the treatment method changes the process shape of the mold profile.

6. The height of the die ejector rod is inconsistent, the contact block of the blank holder ring is not uneven, and the uneven hand of the blank holder ring during the re-stamping process causes the plate to wrinkle and stack. Using a highly consistent ejector rod before installing the die can prevent the metal stamping parts from wrinkling and stacking.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque