What do you need to know about precision parts processing?

Friends who know about precision parts processing know that precision machining is a very strict process, whether it is for cutting or other processes, or the accuracy and size are quite strict requirements of the process. So when machining precision parts, what requirements and standards should be followed to ensure a low or even zero defective rate? The following Fujia industrial editor will introduce the specific requirements and standards for precision parts processing:

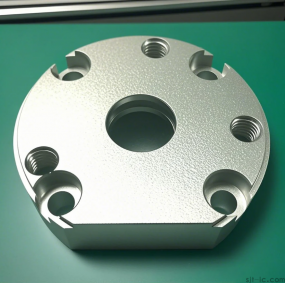

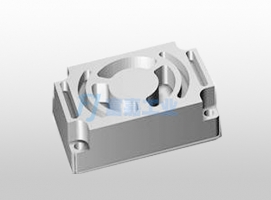

For the processing of precision parts, it is mainly the size requirements, such as the diameter of the cylinder, there are strict requirements, the positive and negative errors are qualified parts within the specified requirements, otherwise they are all unqualified parts; the length, width and height also have specific strict requirements, and the positive and negative errors are also stipulated. For example, if the diameter of a built-in cylinder (take the simplest basic parts as an example) is too large and exceeds the allowable range of the error, it will cause the situation that it cannot be inserted. If the actual diameter is too small and exceeds the lower limit of the allowable negative error, it will cause the insertion to be too loose and not firm. These are all unqualified products, or the length of the cylinder is too long or too short, which exceeds the allowable range of the error. They are all unqualified products and must be scrapped or reprocessed, which will inevitably lead to an increase in cost.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque