What is the machining process of CNC precision parts machining?

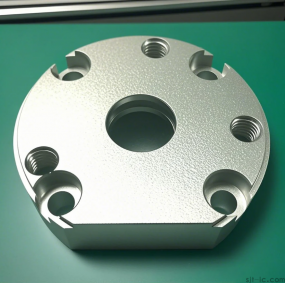

First, product analysis through product analysis should obtain certain composition information and some specific CNC precision parts processing requirements.

The planning of graphics should first be based on a detailed analysis of the product, determine the type of graphics by analyzing the processing requirements, and draw them through graphics software.

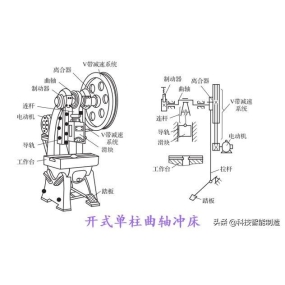

III. Process planning Through the early analysis of the appearance of the workpiece product and the processing requirements of CNC precision parts, each processing process is rationally established from the overall situation of processing.

Fourth, the process of generating the path is actually that we complete the process planning through the software, and at the same time optimize the tool path through the setting of parameters.

After the path is generated, we usually have no intuitive feeling about its performance on the machine tool after all. Here we can check the possible problems through the path imitation, thus reducing the scrap rate of practical processing. The key to the general inspection lies in the effect of the appearance of the workpiece, whether it is over-cut or under-cut, and then whether the process planning of the path is reasonable.

Path output Path output is a necessary process for software planning and programming to complete on the machine tool. Through the path output, the connection between the two can be established by the center reference. If there is a professional set of numerical control, it can also be understood as the post-processing of the tool path.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque