Shenzhen EMAR Precision Technology Co., Ltd. is a professional dedicated to high-precision CNC external processing strength manufacturers, the company has all kinds of advanced numerical control processing machine tools more than 100 sets, we all know that numerical control machine tools to maintain good precision machining accuracy and processing efficiency, must be periodic maintenance of the machine, before, EMAR precision technology for you to simply talk about the maintenance of numerical control processing machine knowledge, today we systematically explain the numerical control processing machine tool cycle maintenance, the main starting point is divided into six months maintenance, quarterly maintenance, monthly maintenance, weekly maintenance and daily maintenance details, take a look.

A. CNC Machining numerical control machine tool half-year cycle maintenance

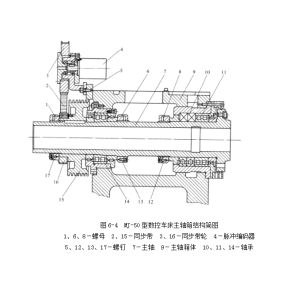

After half a year, the hydraulic system, spindle lubrication system and X-axis of the machine should be inspected. If there is a problem, new oil should be replaced and then cleaned. After fully familiarizing and mastering the knowledge of preventive maintenance, it is also necessary to have a deeper understanding and necessary grasp of the causes and treatment of abnormal phenomena in the hydraulic system. For example, when the oil pump does not inject oil, the pressure is abnormal, and there is noise, etc., you should know what the main reasons are and what corresponding solutions are available.

B. CNC machining numerical control machine quarterly maintenance

Quarterly inspection should be mainly from the machine bed, hydraulic system, spindle lubrication system to check three aspects. For example, when checking the machine bed, mainly look at the machine tool accuracy, machine tool level is in line with the requirements of the manual, if there is any problem, should contact the mechanical engineer immediately. When checking the hydraulic system and spindle lubrication system, if there is any problem, should replace the new oil 6oL and 20L, and clean it.

C. CNC machining numerical control machine monthly maintenance

C. CNC machining numerical control machine monthly maintenance

It is mainly to check the power supply and air dryer. The power supply voltage is normally rated at 180V-220V and the frequency is 50Hz. If there is any abnormality, it should be measured and adjusted. The air dryer should be dismantled once a month, then cleaned and assembled.

D. CNC machining numerical control machine weekly maintenance details

The main items include machine tool parts and spindle lubrication systems, which should be properly inspected every week, especially for the removal of iron filings and external debris.

E. CNC machining numerical control machine daily maintenance work

Its main items include hydraulic system, spindle lubrication system, guide rail lubrication system, cooling system, air pressure system. Daily inspection is based on the normal condition of each system to be tested. For example, when the spindle lubrication system process inspection, the power light should be on, the oil pump should be running normally, if the power light is not on, the spindle should be kept stopped and contact the mechanical engineer. Repair.

The above are the details about the maintenance and maintenance of CNC numerical control machining machine tools for large and small cycles. EMAR Precision Technology Co., Ltd. is based on the medical, optoelectronic and communication industries, focuses on market demand, develops precision parts manufacturing in the fields of automobiles, drones, intelligent machines and office automation, pays attention to and is close to customer processes, quickly responds to user requests, serves users with perfect product solutions, effectively reduces the overall cost of users, and realizes a win-win situation.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque