Introduction to the advantages and disadvantages of CNC Machining

CNC, also known as computer gong, CNCCH or numerical control machine tool, is actually a name in Hong Kong. Later, it was introduced to the Pearl River Delta in mainland China. It is actually a numerical control milling machine. In Guangzhou, Jiangsu, Zhejiang and Shanghai, some people call it "CNC machining center".

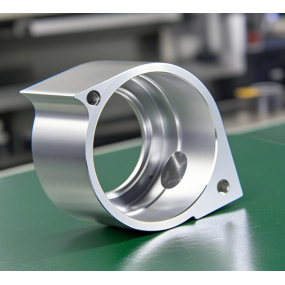

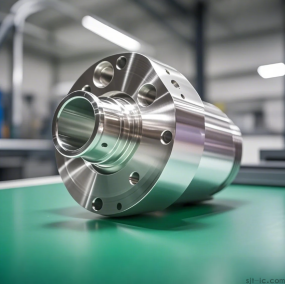

General CNC machining usually refers to precision machining, CNC machining lathes, CNC machining milling machines, CNC machining boring milling machines, etc

Advantages and Disadvantages of CNC CNC numerical control machining has the following advantages: 1. The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the parts, you only need to modify the parts processing program, which is suitable for new product development and modification. 2. The processing quality is stable, the processing accuracy is high, and the repeatability is high. It is suitable for the processing requirements of aircraft. 3. The production efficiency is high in the case of multi-variety and small batch production. It can reduce the time for production preparation, machine tool adjustment and process inspection, and the cutting time is reduced due to the use of the best cutting amount. 4. It can process complex profiles that are difficult to process by conventional methods, and even can process some unobservable machining parts. The disadvantage of numerical control processing is that the machine tool equipment is expensive and requires maintenance personnel to have a high level.

Advantages and Disadvantages of CNC CNC numerical control machining has the following advantages: 1. The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the parts, you only need to modify the parts processing program, which is suitable for new product development and modification. 2. The processing quality is stable, the processing accuracy is high, and the repeatability is high. It is suitable for the processing requirements of aircraft. 3. The production efficiency is high in the case of multi-variety and small batch production. It can reduce the time for production preparation, machine tool adjustment and process inspection, and the cutting time is reduced due to the use of the best cutting amount. 4. It can process complex profiles that are difficult to process by conventional methods, and even can process some unobservable machining parts. The disadvantage of numerical control processing is that the machine tool equipment is expensive and requires maintenance personnel to have a high level.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque