The "sharing economy" is introduced into the machine tool processing industry to help small and medium-sized enterprises realize the construction of unmanned workshops

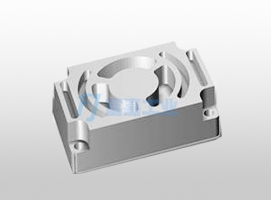

Numerical control machine tool processing (CNC) is an automated machine tool equipped with a program control system. The control system can logically process the program specified by the control code or other symbolic instructions, and decode it through the computer, so that the machine can perform the specified action and automatically process the parts according to the shape and size required by the drawings.

Although China‘s machine tool industry has experienced long-term rapid growth, the level of numerical control still cannot meet the needs of the high-end market. Many mid-to-high-end machine tools still need to be imported, and the price is at a high level. Recently, the investment and finance industry interviewed Ye Jinsong, the person in charge of the shared CNC Machining center project. He plans to introduce the concept of "sharing economy" into the industry, leasing high-end equipment to the demand side to help it expand production scale at low cost.

The demand for mid-to-high-end CNC is promising, and the innovation model is aimed at the pain points of the industry

The demand for mid-to-high-end CNC is promising, and the innovation model is aimed at the pain points of the industry

Ye Jinsong has been working in the machine tool processing industry for 20 years since he came to Guangdong in 1997 to study mold processing. After many years of work experience, he deeply understands the difficulties of many small and medium-sized enterprises in the industry due to the difficulty of financing and high equipment costs. Therefore, combined with the current "sharing economy" trend, he decided to do the project of sharing CNC machining center.

It is understood that the shared CNC machining center is the company‘s purchase of domestic mid-to-high-end CNC (mainly Han‘s Laser and Ningbo Haitian Seiko) and foreign high-end CNC (mainly in Germany), leasing them to small and medium-sized enterprises or individuals in need, or selling them by way of financial lease.

Ye Jinsong introduced that with the development of domestic science and technology, the demand for mid-to-high-end machine tools in the military, aerospace, shipbuilding, 3C industries and the automotive industry continues to increase, especially for high-precision, high-speed, high-efficiency and intelligent mid-to-high-end numerical control machine tools. The demand has increased significantly, and the mid-to-high-end market share will be further enhanced in the future.

Compared with the increasing demand, the supply situation is not optimistic. He pointed out that the technical level of numerical control products of local Chinese enterprises is generally low, especially the core components are purchased from abroad, and some leading companies only assemble high-end products. More than 90% of high-end machine tools are loaded with numerical control systems from foreign companies. The numerical control system known as the "brain" of machine tools has been firmly grasped by a few companies such as Siemens of Germany and Fanuc of Japan in the past. 40% of the manufacturing cost of high-end machine tools in China is purchased from foreign systems.

The rise in costs and the imbalance between supply and demand have made mid-to-high-end machine tools expensive and the financial cost of investing in equipment high. The social financing costs of downstream SMEs using machine tools are extremely high, making many SMEs unable to expand production or transform unmanned workshops.

The team has rich experience in the industry, improves product services, and establishes its own brand

Ye Jinsong is committed to alleviating the problems in the industry with the "sharing economy" model, helping small and medium-sized enterprises or individuals to complete orders with lower start-up capital, or take more orders, and expand production scale at low cost. At present, the company has completed the screening of equipment brands and models purchased by the company, and is negotiating with some leaseholders. At the same time, it is also preparing for the application of 4 personal inventions in the intelligent numerical control system, the application for new company registration, and the expansion of the team.

Ye Jinsong said that there is no similar company in the industry at present, and the project has a first-mover advantage in the market. At the same time, the company‘s team members have worked for many years and have rich experience in operation and design, as well as extensive channel resources, mainly in Guangdong, Beijing and the surrounding areas of Beijing.

The project began mainly by purchasing mid-to-high-end equipment and renting and selling it to obtain rental income. With the development of the project, with more data accumulation (various process parameters), the company will independently develop and produce intelligent series products, establish its own brand, and provide more complete after-sales services. With the "lease + sales" model, it will lay the national market and maintain the industry‘s leading competitiveness.

For the income sources of the project, Ye Jinsong revealed that there are three main parts: rental income, price difference and interest income, and service income. The company obtains lease income in the form of ordinary leasing, equipment price difference and interest income in the form of financial leasing, and service income by providing customers with process improvement and design services. In the future, the company will also obtain sales income through the sale of self-produced own brand CNC equipment.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque