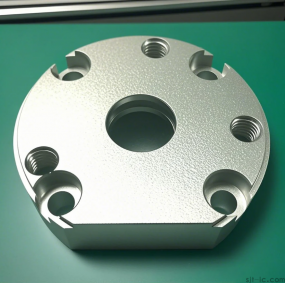

CNC lathe machining: Precision machining should pay attention to some dangers. We all know that if the machine tool is not operated carelessly, it may lead to danger. In the actual operation process, there are many small processing plants that occasionally have tragic incidents due to careless operation and lax management. So what dangers should CNC Machining pay attention to?

First, the probability of danger in the actual operation of the transmission device is relatively large. The transmission of the machine tool is generally composed of gear parts, transmission chains and transmission belts. If these parts are not fully considered in the design of safety, no protective layer is designed, and the rotating part is exposed, then it is very likely that the worker‘s hand or clothes will be twisted into the device, resulting in injury. Second, the pressure part of the pressure machine may cause danger. Generally common punches, crushers, molding machines, cutting machines, etc. are all pressure machines, because most of these equipment need to be operated manually, and the operation of personnel cannot avoid human errors caused by fatigue or mood swings of personnel, so it is also prone to injuries. Third, the danger from machine tools is also a danger. Since machine tools are mostly high-speed cutting machines, they are very dangerous. Factors such as cutting tools, spatter, and impact caused by the improper position of the operator‘s station can all lead to personal injury accidents.

First, the probability of danger in the actual operation of the transmission device is relatively large. The transmission of the machine tool is generally composed of gear parts, transmission chains and transmission belts. If these parts are not fully considered in the design of safety, no protective layer is designed, and the rotating part is exposed, then it is very likely that the worker‘s hand or clothes will be twisted into the device, resulting in injury. Second, the pressure part of the pressure machine may cause danger. Generally common punches, crushers, molding machines, cutting machines, etc. are all pressure machines, because most of these equipment need to be operated manually, and the operation of personnel cannot avoid human errors caused by fatigue or mood swings of personnel, so it is also prone to injuries. Third, the danger from machine tools is also a danger. Since machine tools are mostly high-speed cutting machines, they are very dangerous. Factors such as cutting tools, spatter, and impact caused by the improper position of the operator‘s station can all lead to personal injury accidents.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque