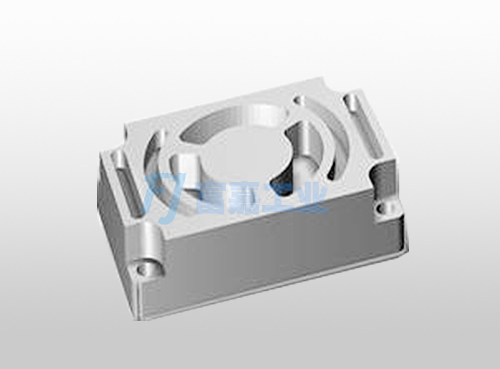

At present, the demand for titanium alloy precision parts processing in the industry is increasing, because it has excellent toughness and excellent corrosion resistance, and can be used to make medical body implants, golf club heads, and military armor.

However, the machining of titanium alloy precision parts is very difficult, which intimidates mechanical technicians. They believe that the super performance of titanium alloy greatly reduces its machinability "ability", making it extremely challenging to cut.

Shenzhen Fujia Industrial Co., Ltd. has been engaged in the processing of titanium alloy parts for a long time. The factory production equipment is all produced by the Japanese Star five-axis numerical control composite milling machine. It has a complete quality inspection system and a complete product parts auxiliary design team. At present, the company has rich production experience in titanium alloy, stainless steel, copper alloy, high-strength steel alloy and other materials.

Shenzhen Fujia Industrial Co., Ltd. has been engaged in the processing of titanium alloy parts for a long time. The factory production equipment is all produced by the Japanese Star five-axis numerical control composite milling machine. It has a complete quality inspection system and a complete product parts auxiliary design team. At present, the company has rich production experience in titanium alloy, stainless steel, copper alloy, high-strength steel alloy and other materials.

Shenzhen Fujia Industrial Co., Ltd. was established in 2000. It is a professional company specializing in precision machinery parts processing, complex precision parts processing, non-standard parts processing and titanium alloy processing. It provides various types of precision machinery parts processing, precision parts processing and tooling fixture processing for solar equipment, medical equipment, electronic equipment, photoelectric communication equipment, and office automation equipment. It has rich experience in high-precision titanium alloy parts processing, shaft parts processing, semiconductor equipment parts processing, etc.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque