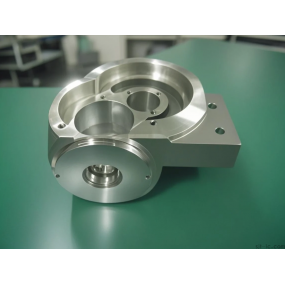

Stamping parts are mainly metal or non-metal sheets, with the pressure of the press, stamped and formed by stamping dies. Compared with castings and forgings, stretching stamping parts have the characteristics of thin, uniform, light and strong. Stamping processing plants can use stamping to make stamping parts with ribs, ribs, rugged or flanged that are difficult to make by other methods to improve their rigidity. Because of the use of precision molds, the accuracy of stretching stamping parts can reach the micron level, and the repeatability is high.

With the improvement of the quality of stamping and drawing die products, the requirements for die quality and life are getting higher and higher. The useful way to improve the quality and life of dies is to develop and use new die materials and new heat and surface treatment processes to continuously improve the performance and processing performance.

Wear resistance is also an important performance index of drawing die. When the part is formed, the metal and the surface of the mold cavity generate relative movement, which wears the surface of the cavity, so that the size, shape, precision and surface roughness of the mold change and fail. The wear resistance of the mold is determined by the heat treatment of the mold, especially the surface heat treatment. The main basis for stamping processing plants to evaluate the wear resistance of the mold is still hardness.  1. Hardness

1. Hardness

2. For hardness > 350HB, the hardness of the conjugate gear is the same as that of the drawing die.

3. In terms of soft and hard tooth surface matching, if the pinion gear is treated with surface hardening, the large gear can be treated with nitriding, carburizing, etc. Taking the steam turbine reducer as an example, the hardness of the automatic gear shaft is 285-320HB, and the hardness of the passive gear is 245-285HB.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque