The unique tool magazine of CNC lathe machining center can realize the function of automatic tool change and spindle orientation, which is more suitable for product processing in the assembly line, so the price is higher than that of general numerical control machine tools. Correct selection is the key to making good use of the machining center and making the CNC Machining center play a role.

CNC lathe machining center selection strategy:

1 Selection procedure

A correct and comprehensive understanding of the machining center is the basis for type selection and ordering. It is necessary to have a comprehensive and detailed understanding and grasp of the performance, characteristics, types, main parameters, functions, scope of application, and deficiencies of the machining center. On the basis of a full understanding, the following procedures can be developed.

2 selection

2 selection

Type selection

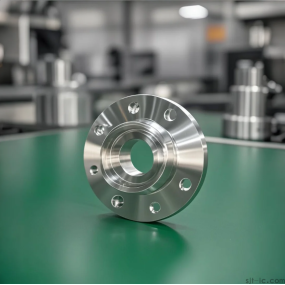

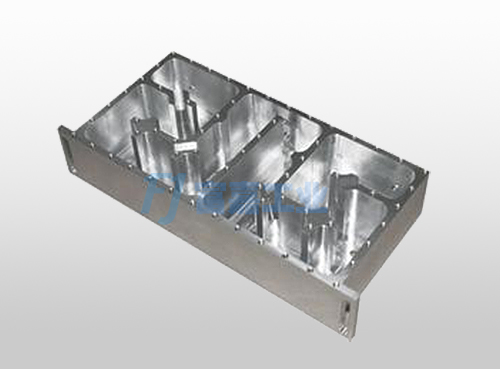

Considering factors such as the CNC lathe machining center process, the processing object with good equipment, range and price, choose according to the selected part family. For example, machining workpieces with more than two sides or holes and surfaces arranged radially around them, such as various boxes, horizontal machining centers should be selected; single-sided machining workpieces, such as various plate parts, should be selected vertical machining centers; when machining complex curved surfaces, such as wind guides, integral impellers on engines, etc., a five-axis machining center can be selected; the position accuracy of the workpiece is higher, and a horizontal machining center is used. When multi-sided machining needs to be completed in one clamping, a five-sided machining center can be selected; when the workpiece size is large, such as machine bed, column, etc., a gantry machining center can be selected. Of course, the above points are not certain, especially the numerical control machine tools are developing in the direction of compounding, and ultimately the decision must be made under the conditions of process requirements and capital balance.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque