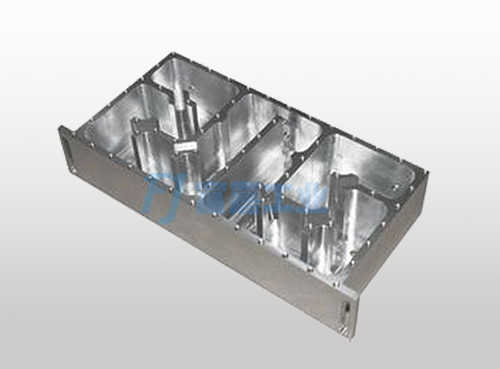

CNC lathe processing has been increasingly used in modern manufacturing, and play the ordinary lathe can not match the advantages, CNC numerical control lathe processing mainly has the following characteristics:

1. The CNC lathe machining transmission chain is short. Compared with ordinary lathes, the spindle drive is no longer a motor, belt, or gear pair mechanism, but a transverse and longitudinal feed is completed by two servo motors respectively. No longer using traditional components such as hanging wheels and clutches, the transmission chain is greatly shortened.

2. High rigidity, in order to match the high precision of the numerical control system, the rigidity of the CNC numerical control lathe is high, so as to adapt to the high precision processing requirements.

2. High rigidity, in order to match the high precision of the numerical control system, the rigidity of the CNC numerical control lathe is high, so as to adapt to the high precision processing requirements.

3. Light drag, the tool holder (table) moves with a ball screw pair, with little friction and light movement. The support-type special bearings at both ends of the screw have a larger pressure angle than ordinary bearings, which are selected when they leave the factory; the lubrication part of CNC numerical control lathe processing adopts oil mist automatic lubrication, which makes CNC lathe processing light.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque