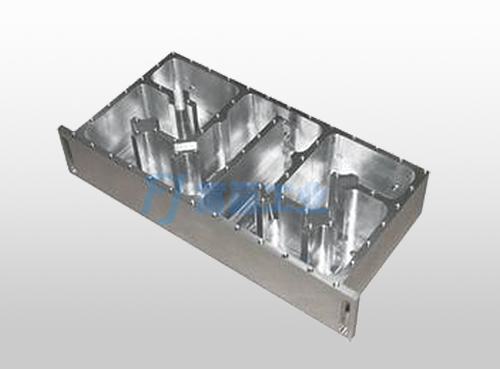

Box parts are typical parts in mechanical parts, such as lathe bedside box, gear transmission box, gearbox, etc., which are one of the basic parts of the machine. It keeps the axes, bearings, sleeves and gears in the machine and components in the correct position, and makes them move in harmony with each other according to the pre-designed transmission relationship to form a whole. The assembled box parts are installed on the machine with the design reference plane of the box, so the processing quality of the box not only affects its assembly accuracy and motion accuracy, but also has a decisive impact on the working accuracy, performance and life of the machine.

First, the design of CNC lathe machining process route

The box requires a lot of surface processing, such as lathe bedside box, gear transmission box, etc. In these machining surfaces, the machining accuracy of the plane is easier to ensure than the machining accuracy of the hole. Therefore, the machining accuracy of the main shaft hole (main hole) in the box and the machining accuracy of the hole system have become the key issues in the process. Therefore, in the arrangement of the process route, I prefer to pay attention to a few points.

(1) The processing sequence of the first face and then the hole

Machining the plane first not only removes the uneven surface of the blank and the surface of the sand, but also more importantly, when machining the holes distributed on the plane, it is convenient to scribe and correct, and when the boring tool starts to bore, it will not generate shock vibration and damage the tool due to the uneven end face. Therefore, it is generally best to machine the plane first.

(2) The rough and finishing stages should be separated

The box structure is complex, the accuracy of the main surface is high, and the cutting force generated during rough machining of CNC lathes,

The box structure is complex, the accuracy of the main surface is high, and the cutting force generated during rough machining of CNC lathes,

The clamping force and cutting heat have a significant impact on the machining accuracy. If the rough machining is performed immediately, the internal stress of the workpiece deformation caused by various reasons after the rough machining is not fully released, and it cannot be eliminated during the finishing process. This results in the deformation of the box during processing and unloading, which affects the final accuracy of the box. I believe that during the rough machining process, it is best to loosen the fixture several times to release the internal stress as much as possible in time to ensure the maximum processing quality of the box.

(3) The decision to centralize or decentralize the CNC lathe machining process

The separation of the coarse and finishing stages of the box body conforms to the principle of process dispersion, but in medium and small batch production, in order to reduce the number of machine tools and fixtures used, and to reduce the number of handling and installation of the box body, the coarse and finishing stages can be relatively concentrated and placed on the same machine tool as much as possible.

(4) Arrange appropriate heat treatment procedures

The structure of the casting box is complex, the wall thickness is uneven, the cooling rate during casting is inconsistent, it is easy to produce internal stress, and the surface is hard. Therefore, sandblasting, quenching and tempering personnel should be reasonably arranged after casting

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque