Ultra-high speed machining technology is an important part of precision machining technology, because precision machining requires high accuracy and small error standards, so it is necessary to work hard on machine tool processing and superhard materials to solve these problems. By improving the high-precision machining ability of machine tools, material cutting speed and so on can be solved.

So what is ultra-high-speed machining technology? Let‘s take a closer look:

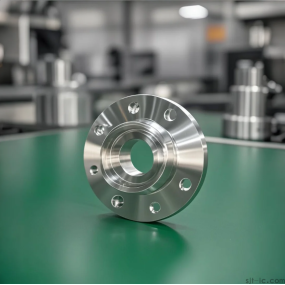

Ultra-high-speed machining technology refers to the use of super-hard materials for cutting tools, which greatly increases the cutting speed and feed rate to improve the data removal rate, machining accuracy, and machining quality.

The cutting speed limit of ultra-high speed machining in Shenzhen machinery processing plant varies depending on the different workpiece data and different cutting methods. At present, it is generally believed that the cutting speed limit of ultra-high speed cutting various materials is: aluminum alloy has exceeded 1600m/min, cast iron is 1500m/min, ultra-heat-resistant nickel alloy is 300m/min, titanium alloy is 150-1000m/min, and fiber reinforced plastic is 2000-9000m/min.

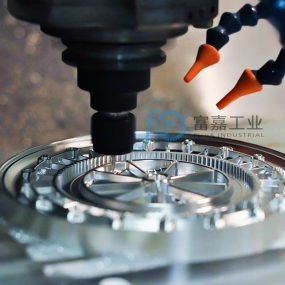

All kinds of cutting, the cutting speed of the process is limited to: turning 700~ 7000m/min, milling 300~ 6000m/min, drilling 200~ 1100m/min, grinding 250m/s or more, etc.

All kinds of cutting, the cutting speed of the process is limited to: turning 700~ 7000m/min, milling 300~ 6000m/min, drilling 200~ 1100m/min, grinding 250m/s or more, etc.

Ultra-high speed machining skills mainly include: ultra-high speed cutting and grinding mechanism research, ultra-high speed spindle unit manufacturing skills, ultra-high speed feed unit manufacturing skills, ultra-high speed machining tools and abrasives manufacturing skills, ultra-high speed machining online active detection and control skills, etc.

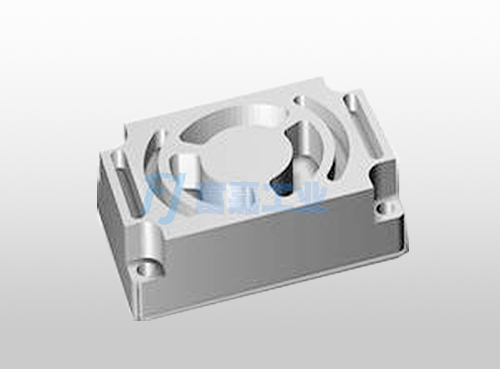

Ultra-fine machining at that time referred to the processing technology with a dimensional accuracy higher than 0.1 μm, a roughness Ra less than 0.25 μm, and a resolution and repeatability higher than 0.01 μm for the positioning accuracy of the machine tool used, also known as sub-micron processing technology, and is being developed towards nano-scale processing technology.

The ultra-fine processing skills of Shenzhen Machinery Processing Plant mainly include: the mechanism of ultra-fine processing, the equipment manufacturing skills of ultra-fine processing, the ultra-fine processing and grinding skills, the ultra-fine measurement skills and error compensation skills, and the premise of ultra-fine processing tasks.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque