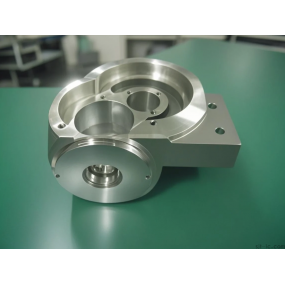

Precision stamping parts processing plants generally experience iron filings during trimming of stamping dies, especially around the lower mold waste knife. Iron filings not only seriously affect product quality and mold appearance cleanliness, but also reduce production efficiency. What should be done to prevent this phenomenon from occurring?

1. Rationalization of edge clearance

The unreasonable method of plate out of shape and edge gap is to use OP10 drawing plate to buckle the profile of each part of the grinding edge mold, and at the same time repair the upper and lower edge gaps and adjust the ingress depth.

2. Waste knife arrangement and structural optimization

(1) Under the premise of the size allowed by the waste conveying equipment and the die structure, the arrangement of the waste knife can be minimized. For example, the Shanghai Volkswagen waste knife specification clearly states that the waste knife should be avoided as much as possible. (2) Optimization of the structure of the waste knife. Compared with the two, in fact, there are only two differences in the Korean waste knife: one is that the edge part only leaves a plane of about 5mm, and the others are all punched into a bevel, so that iron filings will not accumulate. Second, where iron filings may be brought into the mold cavity, the waste knife is made of forgings, not castings.  3. Rotating waste knife

3. Rotating waste knife

The traditional waste knife is difficult to separate the trimming from the waste cutting, especially in the intersection of the waste knife and the trimming edge, where the trimming iron filings are most likely to occur. Shanghai Volkswagen requires a rotating waste knife for the cover waste knife. This kind of waste knife can realize the separation of trimming and waste cutting, which can greatly reduce the occurrence of iron filings.

4. Optimize the mold structure and pay attention to appropriate emptying

Automated or high-speed line production of molds, due to the faster production tempo, if the structure of the stamping die is unreasonable, negative pressure occurs inside the cavity, and the relatively positive pressure air flow outside the cavity sucks the iron filings that occur during trimming into the cavity, and then causes crushing injuries on the surface of the parts. It can also be seen at the production site of the precision stamping parts processing factory that although the molds of Japan and South Korea also lose iron filings during trimming, they rarely bring into the cavity and crush the parts, and the domestic molds often bring iron filings into the cavity. A large part of the reason is that the domestic molds are either not empty or "empty but not through".

5. Install air blowing equipment for improvement

The working process of the sub-trimming die blowing equipment is as follows: between the upper model surface insert and the waste cutter, the blowing pipe is installed, the compressed air valve switch is controlled by the angle of the press slider, and then the iron filings generated by the waste cutter are blown off.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque