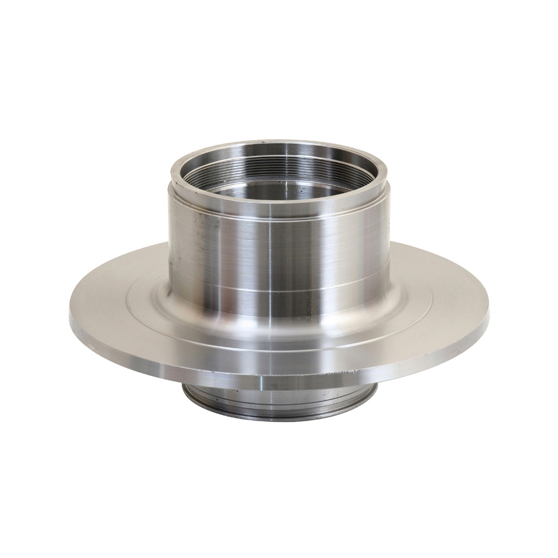

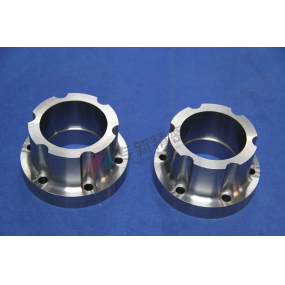

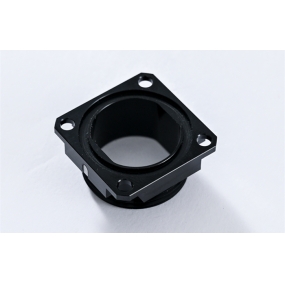

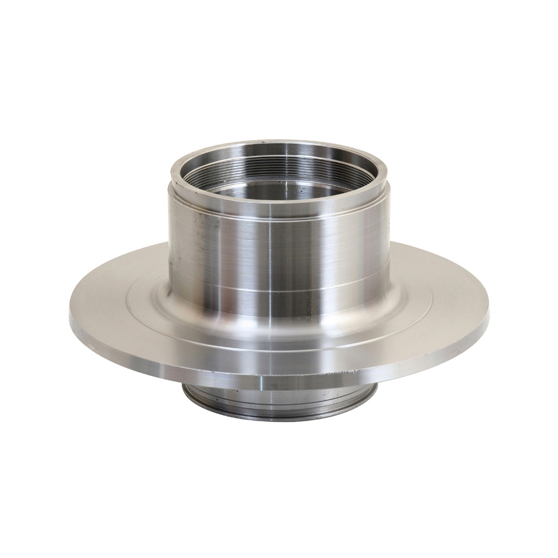

quattuor praevaluationes quinque axis CNC machinaturae centri sunt ut aestimat structuram verticalem et horizontalam swingam et semper verticem potest. The turntable adopts a worm drive structure with high transmission torque, suitable for low speed and heavy duty cutting; Alternatively, torque motor drive can be selected, with fast dynamic response, no reverse clearance, and no transmission mechanical wear, suitable for high-speed, high-precision light load cutting. Instrumentum machinae usus est quinque instrumentum machinae axis aut quinque centrum machinae axis. quinque axis CNC machina in industria aerospace usus est ut partibus corporis, partibus turbinis, et impelleris in superficie liberis. Descriptante motum instrumenti machinae CNC, systemam coordinatorum Cartesian dexteram utilizate; Assis coordinatus paralelatus ad axim principem definitur in axis Z, et coordinatus rotation is ventoris x, y et z axis A, B et C sunt respectively. Usually, five axis link refers to linear interpolation motion of any 5 coordinates, including x, y, z, A, B, and C. 1. Greatly shortened processing time: Due the automatic breakage of the drill bit shape used by global CNC deep hole drilling machines and the continuous discharge of high-pressure chip oil, there is no need to exit the drill bit midway and clean the chips. Velocitate processionis arboris 5-6 vices celerior potest quam illud de Twistris frigidis. 2. Edge grinding of cutting tools: Even without a specialized tool grinding machine, it is easy to grind again. (When proficient, you can grind it by hand). Deep hole drilling can be ground 50-60 times. Therefore, the service of deep hole drill bits is longer. Compared with Fried Dough Twists drills, the cost of cutting tools is not high. 3. Procedentes materiae cum alta duritate: a causa de facto, quia profunda rupa fluctus profunda CNC drills (drills in tres axis profunda rupa drills, quinque axis profunda rupa drills) de difficile ligatur, materiae cum difficile HRC40 procedere poterunt. 4. Delum abysso quinque axis adopt design integratum: slider in tota tabula diagrammarum per axis centrum hingetur, et servo motor condit diagrammarum ad rotationem per diminutorem. Dispositio rotation is in axis centro installatur ad controllendum angulum rotationis, ita ut spindle in quaeculum angulo in processionem, positionem et fortitudinem dilectionis accipiat.

Latin

Latin » »

» »

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque