Stamping die is a special process equipment used in cold stamping processing to process materials (metal or non-metal) into parts (or semi-finished products), known as cold stamping die (commonly known as cold stamping die).

a. Unus processus mollus est mollus, quæ solum unum pertinet in unum plagam press.

b. Molda composita unum est workstation, et in una stroca press, mold a est, qui conclusit duos aut plures processos pulsere simul in eadem workstation.

c. Mors progressivus (etiam continuous die) habet duas aut plures workstationes in directo nutritionis raw material is. It is a mold that completes two or more stamping processes on different workstations in one stroke of the press.

d. The transfer mold combines the characteristics of single process molds and progressive molds. By using a robotic arm transfer system, the product can be quickly transferred within the mold, greatly improved production efficiency, reducing production costs, saving material costs, and ensuring stable and reliable quality.

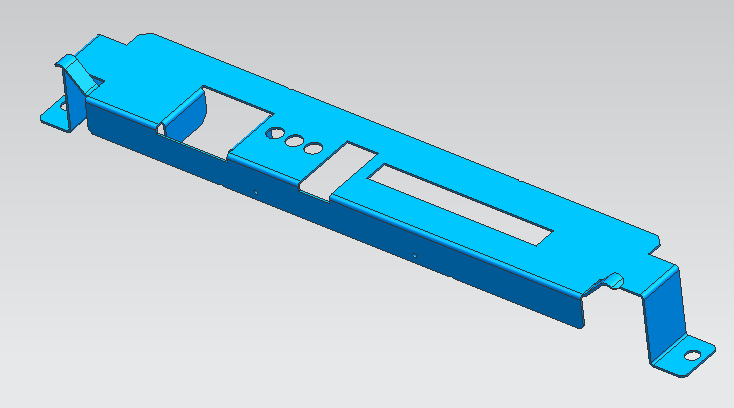

Produktus finitus est sicut sequitur

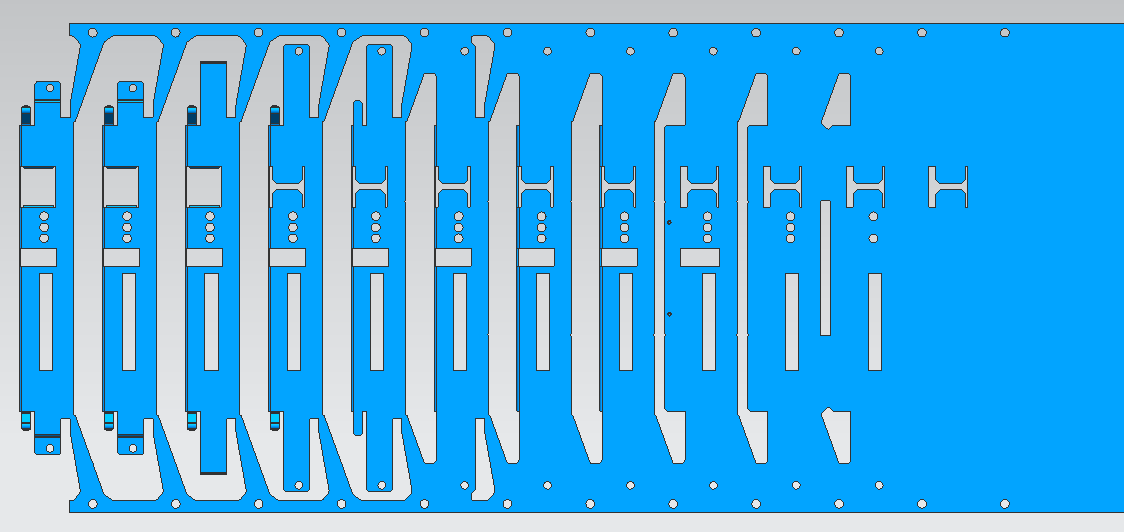

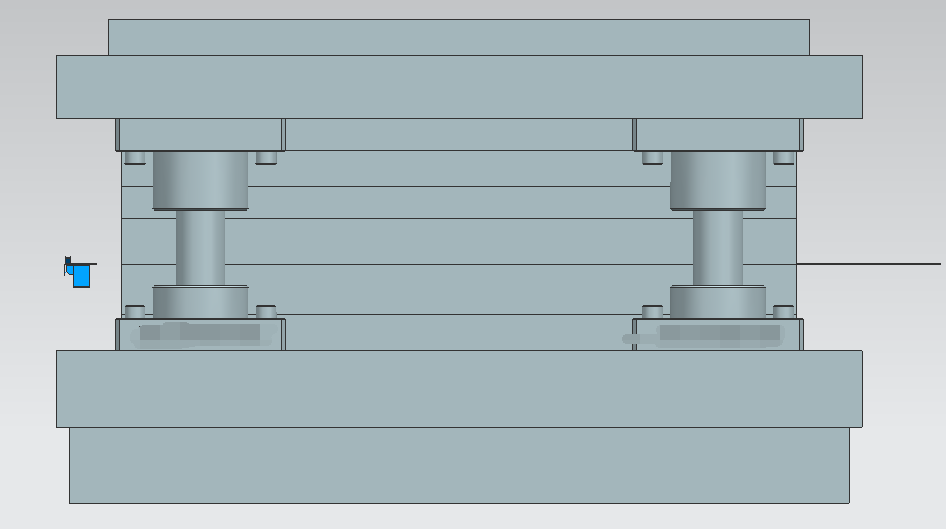

Distributed stamping is shown in the following figure

Quid de hoc consilium?

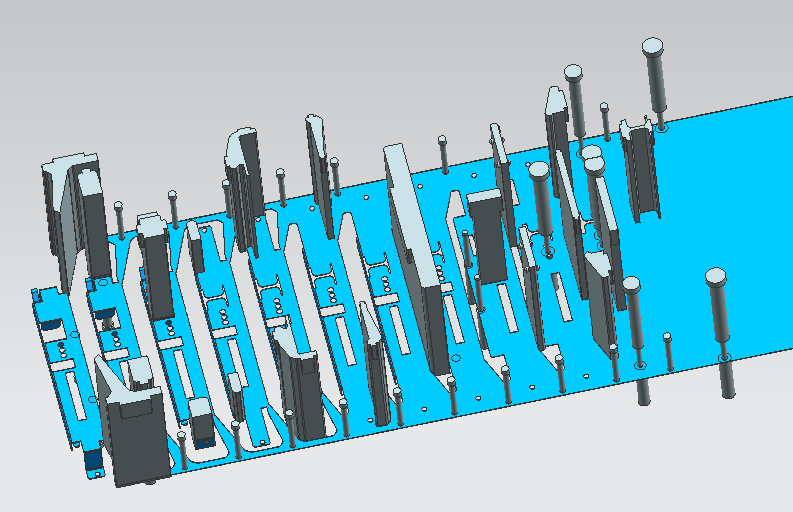

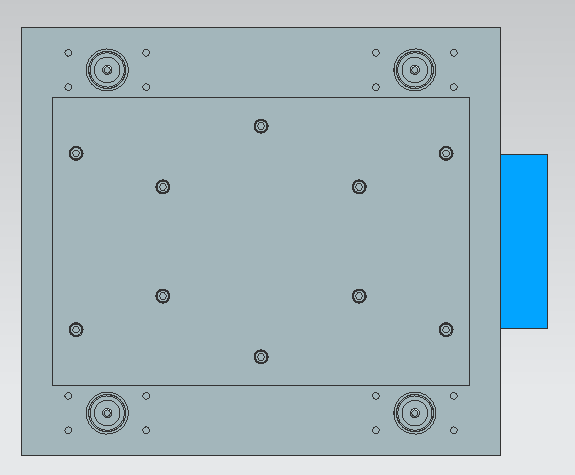

The arrangement of punching needles is as follows

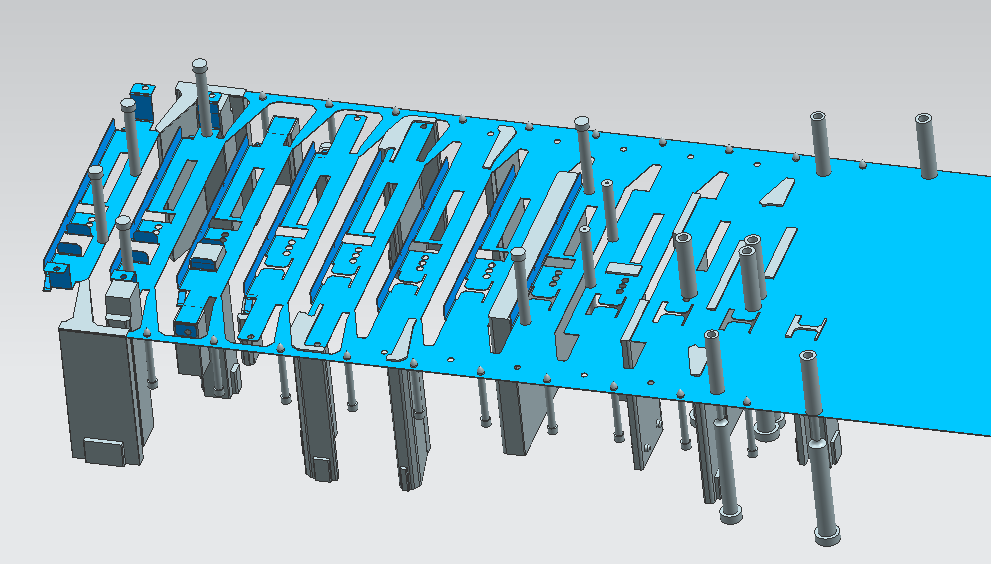

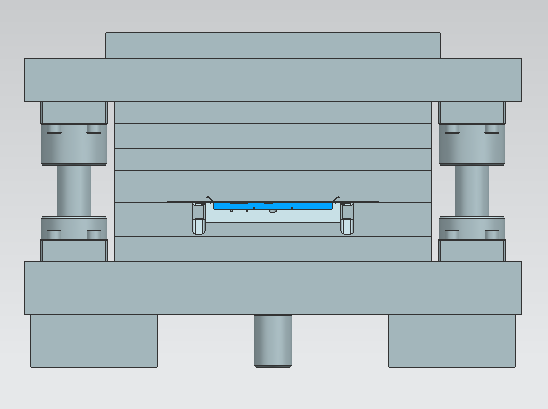

Total structure of the mold

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque