1,High demand rotating parts 1 Parts with high precision requirements, due to the good rigidity of CNC lathes, have high manufacturing and tool setting accuracy, and can be easily and accurately machined

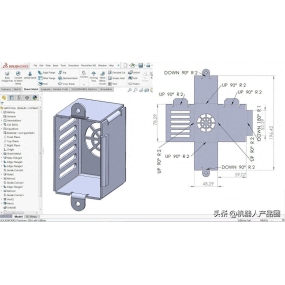

Work compensation or even automatic compensation, so it can process parts with high dimensional accuracy requirements. In general, conversion parts with seven levels of dimensional accuracy should not be difficult. In aliquid situationibus raedas pulsere possunt. In addition, due to the high-precision interpolation operation and servo drive of the tool movement during CNC turning, coupled with the good rigidity and high manufacturing accuracy of the machine tool, it can process parts with high requirements for straightness, roundness, and cylindricity of the generatrix. Formus arcarum et alterum curvas contourum est multo proximus ad figuram geometricam in drawinge quam illud lathe copyationis. Parts with curved generatrix shapes are often inspected using CNC wire cutting and slightly polished templates. Precisio formae partium quae a conversione CNC producuntur non inferior erit ad precision formae suae prototipi. CNC conversatio optime efficata est in improving precision positivae. Multi partes quas alta positiva accuractia requirant non potest cum latis tradicionalis conversari et solum per subsequente grinding aut alios modos compensari potest. Precisio positionis partium conversionis prima dependit on the number of times the parts are clamped and the manufacturing accuracy of the machine tool. If high positional accuracy is found during machining on a CNC lathe, it can be corrected by modifying the data in the program, which can improve its positional accuracy. However, it is not possible to perform this correction on traditional lathes. 2. A rotary CNC lathe with good surface roughness can process parts with low surface roughness, not only due to the rigidity and high manufacturing accuracy of the machine tool, but also due to its constant speed cutting function. When the material, precision machining allowance, and cutting tool are determined, the surface roughness depends on the amount of feed and cutting speed. At turning the end face on a traditional lathe, due to the constant speed during the cutting process, theoretically only a certain diameter has the smallest roughness. In fact, it can also be observed that the difficulty inside the final face is inconsistent. Using the constant speed cutting function of a CNC lathe, the optimal speed linear can be selected to cut the end face, resulting in a small and consistent roughness. CNC lathes are also suitable for turning parts with different surface roughness requirements. Areas with low difficulty can be achieved by reducing the amount of cutting, which is not possible on traditional latches. 3. Ultra precision and ultra-low surface roughness parts such as magnetic disks, recording machine heads, multi sided reflectors for laser printers, optical equipment such as rotary drums for copiers, lenses and molds for cameras, as well as contact lenses, require ultra-high contour accuracy and ultra-low surface roughness. They are suitable for processing on high-precision and high-performance CNC lathes. Lenses used for plastic astigmatism that were previously difficult to process can now also be processed using CNC lathes. The contour accuracy of ultra precision machining can reach 0.1 μ m, and the surface roughness can reach 0.02 μ m. The minimum setting unit of the CNC system used for ultra precision machining should reach 0.01 μ m. The material of ultra precision turning parts used to be mainly metal, but now it has expanded to plastic and ceramics. 2 , propter functiones interpolation is linearum et circularum CNC lathiorum, alios dispositivos CNC etiam functiones interpolationis curvae non circularum habent. Pro hoc, potest convertere partes rotarias formas complex as compositas ex lineis rectis et curvae planaris, etiam partes difficilis dimensionibus controlli, sicut partes shell cum claudis surficibus interioris formationis. In figura 5-1 monstrata est superficie speluncae interioris inclusionis particuli parva os et venter magnum, quod in lathe regulari machinatur non potest, sed facile machinatur in lathe CNC. Curvas qui fabricant contum parterum a equationibus mathematicis aut curvas listatis descriptae sunt. For contours composed of straight lines or arcs, directly use the straight line or arc interpolation function of the machine tool. For contours composed of non circular curves, non circular curve interpolation function can be used; Si instrumentum machinae elegitae non habet functionem interpolationis curvatoris, primum line a recta aut arca accedet, et tunc interpolatum est et secundum functionem interpolationis lineae rectae aut arcae interpolationis. If both traditional lathes and CNC lathes can be used for turning circular and conical parts, then CNC lathes can only be used for turning complex shaped rotating parts.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque