Importantia altae difficultatis pulseris materiae mortis

Stemping mold is a commonly used mold in industrial production, which is formed by stamping on metal sheets through the mold to achieve the desired shape and size. Stamping molds are important tools for manufacturing various metal products, such as components for automobiles, machinery, electronics and other products. Pro hoc qualitatem et perfectionem mollium pulserum crucial est pro qualitate et functione produktorum. Fortitudo stampionis materiae moriae est unus de factoribus importantibus qualitatem et actionem suam determinantes. Altior material difficile potest certare resistentiam vestimenti et durabilitatem molae, permittant illum multo tempore in productione sine deficito. At the same time, material hardness also affects the accuracy and efficiency of stamping forming, as molds with high hardness can better maintain their shape and size, thereby better ensuring the quality of the finished product. Pro hoc, elegit adequatum stampionem materiae morientibus et secundum altam duritatem eorum est step importante in manu superqualitatis stampionis morientibus.

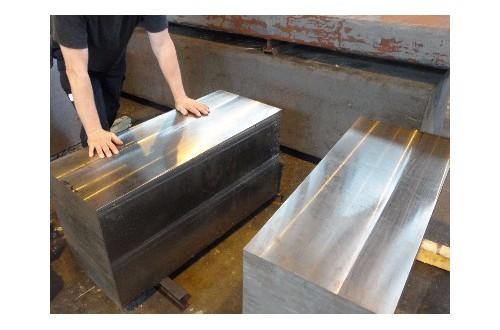

Common stamping die materials

In hoc tempore, communem gestationem materiae morientibus includent sequentes:

1. Stola velocitatis alta (HSS)

Vellum velocitatem est ferrum altitudinis cum characteribus sicut fortitudo alta, fortitudo alta et resistentia alta.

Unus est ex ideal is materialibus ad fabricationem alta precision et alta qualitate stampionis mollis. Fortitudo altae velocitatis steel is usus inter 60 ~70HRC est, qui potest confortare opus maximae pulserum. At the same time, high-speed steel has also good processing performance, and its hardness and wear resistance can be improved through processes such as heat treatment.

2. Alloy tool steel

Stella Alloy est typus fertilis fertilis qui continet elementos allogandum, qui habet altum difficile et resistentiam gerit. Usually it used to manufacture large and complex stamping molds because its hardness can reach 70-80HRC, making it more suitable for manufacturing high-quality molds than high-speed steel.

However, the processing performance of alloy tool steel is relatively poor, requiring higher processing difficulties and cost.

3. Stella speciala

In addition to high-speed steel and alloy tool steel, there are also special steel materials that can be used to manufacture stamping molds, such as cold work mold steel, hot work mold steel, stainless steel, etc. Haec materia proprietatem et utilizationem habent, et materia adequa elegere sunt based on specific production requirements.

Comparison Table for Hardness of Stamping Mold Materials

The following is a commonly used difficulty comparationis table for imprimisation materiae: materiae: nomen Material: Hardness.Stella ASP60. 62-68. Stella M2. 60-65. Stella M42. 65-70. Nota est, quod materia diversa pulsera morientur habent diversas necessitates difficultatis in diversis productionibus. When selecting materials, it is necessary to determine the most suitable material and hardness based on the actual situation.

Quomodo improvisi fortitudinem pulseris materiae morientibus?

In addition to selecting suitable materials, the hardness of stamping die materials can also be improved through the following methods:

1. Treatment calide

Treatura calefacti modo usus est ut difficiles materiae meliores faceret. Conducentes calefactibus et frigidis procedentibus materiae, crystalis structura et proprietates illius cambiare potest, tunc improvens difficultatem eorum et resistentiam portare. Metodos calefactionis usus sunt extinguere, temperatura, normalizare, etc.

2. Meditate superficie

Surface treatment is a method of improving the hardness and wear resistance of a material by altering its surface structure and properties. Common surface treatment methods include nitriding, carbonization, nitriding, etc.

3. Coating treatment

Coating treatment is a method of coating a material surface with a special layer to improve its hardness and wear resistance.

Materiales commune coatingum titanium, nitrides, carbides, etc. Notum est, quod si supra metodes difficultatem et resistentiam materiae habere poterunt, etiam in alteris proprietatibus materiae, sicut difficile et difficile, efficient. Hoc ergo, cum haec metodes elegit et utilizat, necesse est intellegere rex situationem.

conclusion

Fortitudo stampionis materiae mortuorum est factor importante in manufacturo superqualitatis stampionis mortuus est. Elegans adequatus materiae et improving their hardness through appropriate methods can ensure that the mold will not fail during long-term use in production, while also improving the accuracy and efficiency of stamping forming. In process seleccionis et imprimisi materiae mortis, necesse est comprehensive considere situationem factam et elegere materiales et metodes optimum adequatos.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque