Quotatio non includet costas transportationis et profita (a mercato based on MOQ), quae non sunt in costa includitae.

Valor profiti adjusta est based on MOQ:

MOQ< 5PCS Profit=Costa X60%

MOQ< 20PCS Profit=Costa X50%

MOQ< 100PCS Profit=Costa X40%

MOQ< 200PCS Profit=Costa X30%

200< MOQ< 500 Profit=Costa X25%

MOQ> 500PCS Profit=Costa X20%

Profit=(material cost+table processing fee+purchased parts fee+material loss fee+processing fee+transportation fee) X profit parameter

=depends on MOQ (20% -60%)

Final quotation of the product=material cost+surface processing fee+external procurement fee+loss fee+processing fee+transportation fee+profit

Costa materiae platae (platea steela, etc.)=volumen x gravitate particula x unitate precisa=longitudine x latitudine x plateae densitate x densitate x perdita x precisa unitate

Note: (Density: Mass per unit volume, Specific gravity: Weight per unit volume.) Actually, it's basically the same, but later in 1984, the term weight was removed from the national unit of measurement, so specific gravity became a thing of the past. Nowadays, what we verbally call specific gravity is actually density.

Loss rate: Cabinet/rack=115% Chassis/rack=122% Box=130%

=length of the profile on the drawing+10mm

Net weight=cross-sectional area of aluminum profile x actual material length (drawing profile length+10m m)/10x1000000 x quantity x density (2.75g/m ³)

Gross weight=net weight x loss coefficient (cabinet 115%, plug-in 122%, box module 130%)

=unit price x gross weight

Material loss cost=(material cost+surface processing fee+external parts cost) X0.03 (0.03 is the loss rate)

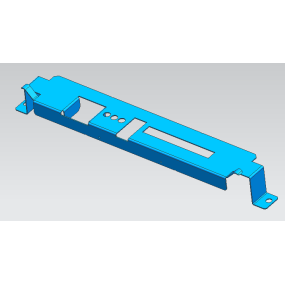

Actual material used for sheet metal parts=longer edge of the unfolded surface x shorter edge of the unfolded surface x loss coefficient

S loss coefficient formula=actual processing area/developed area of the part

1. Quando S< At 0.05m ², the loss coefficient is 1.38%

Quando 0,05m ²< The loss coefficient at S< 0.1m ² is 1.23%

3. Quando 0.1m ²< The loss coefficient at S< 0.25m ² is 1.17%

4. Quando 0.25m ²< The loss coefficient at S< 0.6m ² is 1.12%

5. Quando S> The loss coefficient at 0.6m ² is 1.06%

When MOQ< At 100PCS, the cost of preparing the computer bed equipment is required. Formula=(30-50) X Number of sheet metal parts/MOQ

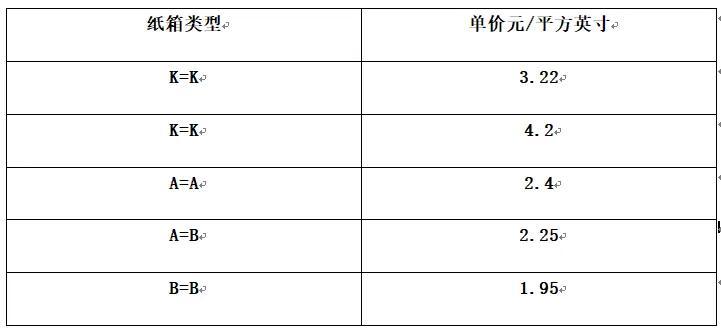

Typus Cartonis (cata cista 20 kg superire non potest)

Algoritmus Cartonis: [(longitudo+latitudo+2) x (latitudo+altitudo+2)]/500x pretio unitatis, i.e. inches quadratis/500x pretio unitatis

Paper/flat card algorithm: (length+1 inch flash) x (width+1 inch flash)/1000x unit price

Algoritmus saccis Plastique: 0.08x longitudo (m) x latitudo (m) x 1.84x pretium universis (anti static 16 yuan/kg, regular PE 15 yuan/kg)

Common wooden board specifications: 800X600X140, standard 5T vehicle can accommodate 36 wooden boards, and the height cannot exceed 1.5M

Specification of extended wooden board: 2000X800X140 (each board cannot exceed 400Kg)

=L9MxW2.4MxH2.5M (volume=54m ³)

Freight including tax=500/Total quantity loaded x 1.17

Total quantitate loading=(longitudo tabulae ligneae/longitudinis tabulae tabulae) x (latitudo tabulae ligneae/latitudinis tabulae tabulae) x (altitudo tabulae tabulae 1500/altitudinis) Unitate: mm

Exemplo: Dimensio Cartonis: 9 (1/2) x9x7 (1/2) 2PCS per box

Longitudo 9 (1/2) x 25.4=241.3 800/241.3.=3.319 (sume integrum)

Width 9x25.4=228.6 600/228.6=2.62 (taking whole numbers)

High 7 (1/2) x25.4=190.5 1500/190.5=7.87 (rounded to whole number)

=3x2x7x2x36=3024

Card usage=freight including tax x 36/500 or=1/total number of cards per card

Tempus ecclesiae rationale esse, et sub 2U, non potest ultra 1,5 yuan

Screw assembly/riveting time: 1U=25S, 2U=35S, cabinet/rack/chassis=45S

The standard assembly time for cardboard boxes is 40 seconds

Procedentes costas pro singulis partibus

Cutting=2 yuan/minute

Shuchong=3.35 yuan/minute

Laser=4.47 yuan/minute

Bending L< 600mm=0.36 yuan/culter L< 1200mm=0,55 yuan/knife L ≥ 1200mm=0,8 yuan/knife

Polishing/polishing=0.45 yuan/minute

Drilling/chamfering/sinking/tapping=0.08 yuan/hole

Drawing=19 yuan/M ² oxidation=20.5 yuan/M ²

Electric welding=0.97 yuan/minute (full welding 1cm=15S, spot welding one point=12S)

Calibration/machining=1 yuan/minute, collision welding=0.12 yuan/point

Mater seminis/columna=0.12 yuan/PCS

Artificial punching machine: 45T=0.13 yuan/time 60T=0.16 yuan/time 80T=0.2 yuan/time

110T=0.25 yuan/time 160T=0.29 yuan/time 200T=0.33 yuan/time

M250T=0.35 yuan/time, 400T oil pressure=0.49 yuan/time

Impressio schermi: 0.65 yuan/time

Assembla: 0.5 yuan/minute (clausur 0.1 yuan/pcs, flumina 0.05 yuan/pcs, flumina 0.08 yuan/pcs)

Back glue=100 yuan/M ²

Spray coating: G127/G150=21.8 yuan/M ² G129/G107=20.1 yuan/²

G108=25.9 yuan/M ² G139=43.7 yuan/M ²

G133=44.4 yuan/m ²

Stainless steel passivation (G011)=5.98 yuan/kg

Plating Nickel=8,12 yuan/kg

T001=6 yuan/M ²

G002=25.64 yuan/M ²

Tin plating=273.05 yuan/M ² Silver plating=99.27 yuan/M ²

Omnes pretiosa universis hic non includent taxas

Calculatio tonnagi machinae punching manus: P=TxCxMX1.3/1000 tonnis

T=material thickness C=punching perimeter M=shear strength 1.3=sum of unloading force+pushing force+top material force

Film 18 yuan/sheet (A4), film algoritmus (non A4)=length x width x 0.08 minimum (20cm x 30cm) x 0.08=48 yuan

Standard working hour statistics table

Laser cutting hours (T=0.5-1.5)

Horae opus ad cargam/discargam singulam partem opus=1 minuta/1. Numero pars quae ex toto parte materiae secere potest

Numero partium universae materiae=[2500 (longitudo plateae standard/longitudo operantium)] x [1220 (latitudo plateae standard nostra/latitudo operantium)

Laser cutting working hours (T=2.0-2.5)

=number of cutting holes x average cutting speed+cutting edge length x average cutting edge speed

The loading/unloading time for a single workpiece is 1.5 minutes per piece of material that can be cut

The number of pieces that can be cut from the entire piece of material=[2500 (effective length after removing excess material/length of workpiece)] x [1220 (effective width after removing excess material)/width of workpiece]

Relax rate:

1. Line changing is generally 5% (cutting a small number of workpieces)

Time required for X-axis movement is generally relaxed by 3% -5%

3. Tempus motionis Y-axis opus est a 1% -3%

Laser (T3.0-3.5) est supra

Laser (T4.0)

=loading/unloading time+number of cutting holes x average cutting speed+cutting edge length x average cutting speed

The loading/unloading time for a single workpiece is 1.5 minutes per piece of material that can be cut

The number of pieces that can be cut from the entire piece of material=[2500 (effective length after removing excess material/length of workpiece)] x [1220 (effective width after removing excess material/width of workpiece)]

1. Cutting bed working hours=(material handling CT+cutting CT) x number of people=total CT time x number of people

2. The material handling operation takes 10 minutes (2 minutes to push the cart to the raw material warehouse+4 minutes to load the cart+4 minutes to push the loaded cart to the cutting bed), with a maximum of 20 pieces per cart. The formula is 10 minutes/the number of workpieces that can be cut per piece of material/the maximum number of materials per cart is 20 pieces

3. CT time=(homework time+homework time) x relaxation rate

4. Relax rate includes: 1. Physiological relaxation of 5% -10%, such as drinking water or using the toilet

2. Relax fatigue by 2% -8%, such as resting or waiting for work

3. Relax efforts by 1% -5%

=loading and unloading time+punching time+tool changing time

Nota, quaeso, quia pulveres in stock aut produktis non sunt, cum paletas speciosas colores in quotatione.

Quando pulvere non est disponibile, in produktum a tempore 100KG distribuetur, cum pretio unit at is 25 yuan/KG

About 2500 yuan will be allocated to MOQ as purchased parts

Special powder spraying algorithm=25 * 100/MOQ

Take similar sand and orange grain codes for manual codes in the quotation template

Allocatione molda costis:

For example, in 20230328, if the demand for this code is 10000 sets and the mold cost is 10000, 50% of the order (i.e. 5000 sets) will be allocated to these 5000 sets. If the customer requests to allocate it to these 5000 sets, the mold cost allocated to the product will be 10000/5000=2 yuan. If it exceeds 5000 sets, the price will need to be lowered again (the mold cost is no longer included in the excess part)

MOQ< 3000, same mold processing cost, same CNC processing cost, minimum MOQ ≥ 2500

Exemplo: Mold fee of 16000 yuan, MOQ=4000PCS

Post partem unius mold=16000/4000=4 yuan

Costa externorum partes et processionis secundum moldus est 10 yuan

Vere costa est 10+4=14 yuan

Actual market reported expenses to customers=cost x profit

When MOQ< 3000PCS customers do not agree to mold opening. If the CNC of the parts can meet the processing requirements, the mold will not be opened.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque