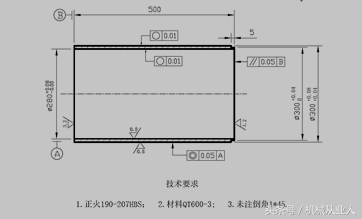

1. Analysis of part drawings

1) The coaxiality tolerance of the outer circle to reference A is ± 0,05mm;

2) The parallelism tolerance of the right end facing the reference plane B is 0,05mm;

3) The roundness tolerance of the external surface is 0,01mm;

4) The roundness tolerance of the inner surface is 0,01mm;

5) Normalised 190-207HBS;

6) Material QT600-3

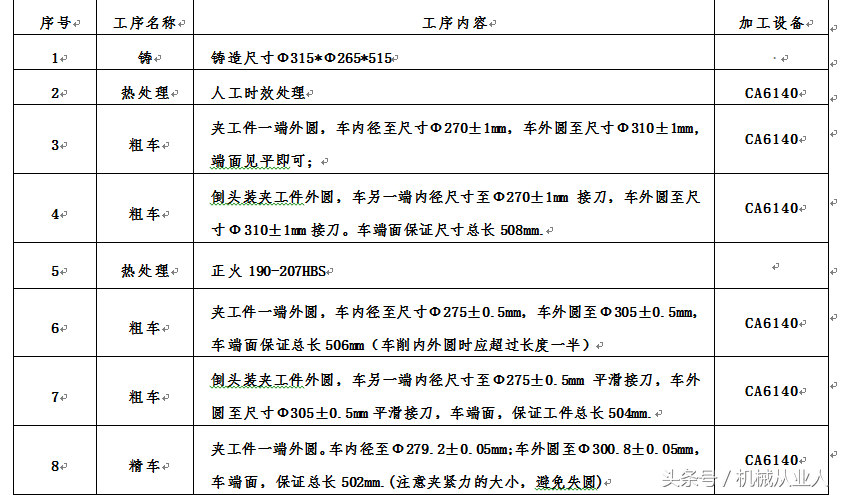

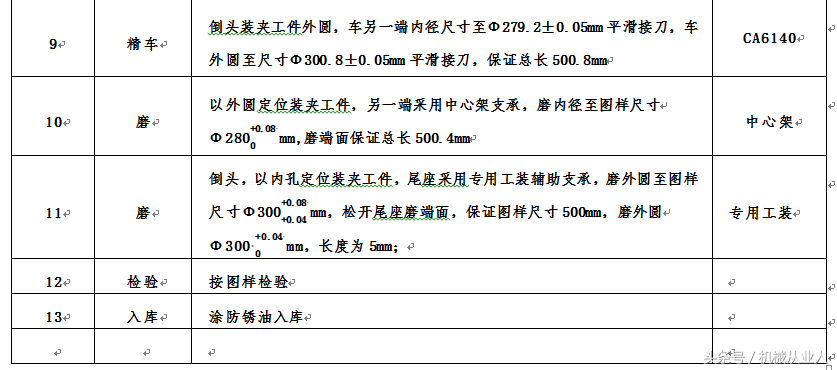

2. Cylinder liner machining process card

3. Analisi procedentis

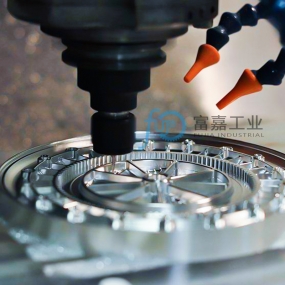

1) Lineae cylindri tinctis partibus est. Due pauperum rigiditatem thin-walled workpieces, they are prone to deformation during the turning process due to cutting and clamping forces, which affects the dimensional and shape accuracy of the workpiece. Therefore, reasonable selection of clamping, tool angle, cutting amount, and cutting cooling lubrication are all key factors to ensure the machining of thin walled parts;

2) Precisio circulorum interiorum et exteriorum parterum relative altum est, et robustum et pulchrum machinationem inter processionem separabitur;

3) When the cylinder liner is finally used, it is pressed into the cylinder block and the internal diameter size is machined again. The end of the cylinder liner with a diameter of 300 (+0.04/0) * 5mm plays a positioning and guiding role during pressing.

Explanation:

1. A causa de nescientia tolerantium superioris et inferioris et cartas procedentis in documento import are, aliquid partes in formato imaginis sunt;

2. Scripta cartarum procedentium non est unica. Utrum machinas ordinaras in exemplum accipiant, spero ut utile esset.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque