Con conversionem conscientiae videi et consummationis hominum necessitates sunt, crescens postulas tabulatorum metalorum inter multos homines factus est. Our common metal tableware uses edible 304 stainless steel, which combines safety, environmental friendliness, and aesthetics. So how was this type of tableware produced?

Materium crustum tabulae calicis calicis est certe calicis inmaculatus, quod secitur et secitur in plateis calicis inmaculatus. Cubiculas calicis inmaculatis quasi exemplum necessaria est ut machinam laser is seceret et seceret materiales in plate a calicis inmaculatis secundum mensuram maculae Sequentes gradus similes sunt antiquum procedurae auri et argenti fabricationis. Materium succidit semper fabricatur, et finem totum processionem perfectum est per gestionem mortem pro stampionis.

Utilia in cafeteria nostra facta processuntur aedem methodo quam cūkas. Procedus omnium tabulatorum metallorum similitudinem habet, quod primum machinam laserorum sequitur ad secendum, et qui punctum est, primum in tabula punctum est. Then proceed with stamping forming.

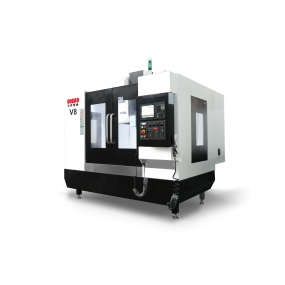

laser cutting machine

laser cutting machine

It is worth noting that the current cutting process has greatly improved compared to before. Laser cutting machines can cut and align themselves according to the drawings, reducing material waste and lowering production costs. Design and complete the required cutting requirements according to the drawings; Knowing the production process of metal tableware makes the food delicious.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque