In the CNC Machining of threads, how to determine the cutting parameters of threads is probably chosen by many frontline operators based on experience. It is undeniable that practitioners can gradually explore and find cutting parameters that are in line with the actual production of enterprises through careful observation over time. However, for most practitioners, it is necessary to further master some empirical formulas of thread cutting in order to quickly grasp the precautions in thread cutting process.

Think about it, in the entire CNC machining process, thread machining is the most complex and involves the most formulas. Exemplo, quam est latitudinem instrumenti sequentis ad machinationem virgae? Quomodo maiorem diametrum, minimum diametrum, et diametrum externum calculari est? Quot horae interiores effectae sunt? Quid velocitas spindali ferri est? Quomodo sinistra et multi ligna agentur? Quot vicibus ferrum pascitur et quid ferrum radicalum pro singulis instrumentis est?

quidam enim praecipientibus cognoscentur et principibus numquid difficile invenient Estne etiam quod solum in experientia magistrae processum est? Estimat hoc articulum scribere pro novissimo. Listam et summarizam relevant scientias punctus de usus triangular is exterioribus in machinis CNC.

Thread processing

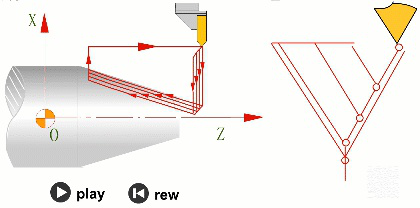

Ex grafeo videtur quoniam cutor ligna quattuor vicibus ambulavit, et fertilis radial is graduum declinet. Quanti semel minuet? If the thread cutter needs to run 3 times, 5 times, etc., how much radial feed should be taken for each run? Hoc est sermo importante ad discutionem hodie!

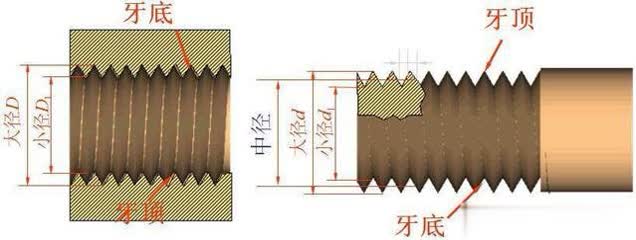

Basic parameters of threads

In actual machining, the outer diameter d of each actual cutting thread is different. For plastic materials, d=d-0.1p; minor diameter d2=d-2H=d-2X0.65 (0.54) P, where 0.65 represents the empirical coefficient; Velocitate maxima n spindle est 1200, n1200/p-80, et 80 est factor securitatis, quod etiam formula empirica est. Fertilibus F F est f=p unius virgae et f=S multitudinis virgae. Altissimus est maximus, sed ad explicationem numeri passorum et fertilium temporis pro singulis lignis.

In armatura lignorum, quando tempore pascuae continuo declinet, est etiam formula calculi pro tempore pascuae singulorum viarum, sicut sequitur

Ax representat the radial feed rate each time, n represents the number of tools passes, and j represents the number of tools passes per pass. The first pass is 0.3, followed by 1, 2, 3..., depending on the number of cuts completed.

Exemplo, in lignis externis cum alto 1,5mm, tota profunditudinem dierum 0,94mm et 6 fertilibus transibit, tempora fertilis per singulam passam calculata est sicut sequentes

Primus cutus: a1=0.94/50.3=0.23mm;

Secundum cutum: a2=0.94/51=0.42mm, cum fluctum rate 0.42-0.23=0.19mm;

Tertius secitus: a3=0.94/52=0.59mm, cum fluctum rate 0.59-0.42=0.17mm;

Quartus secitus: a4=0.94/53=0.73mm, cum fluctus velocitus 0.73-0.59=0.14mm;

quinta secitus: a5=0,94/54=0,84mm, cum fluctus 0,84-0,73=0,11mm;

Sexto secessio: a6=0.94/55=0.94mm, cum fluctus velocitus 0.94-0.84=0.10mm;

Profesionis enim, qui frequenter procedere ligna, propositur supra formulas magistrare.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque