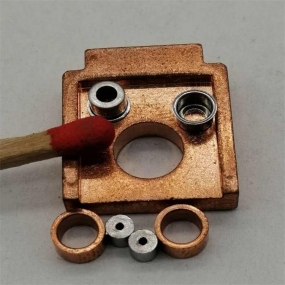

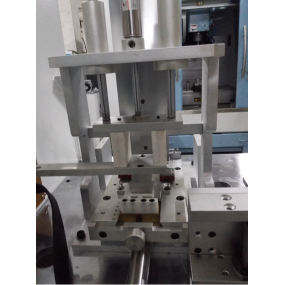

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

quattuor praevaluationes partes metallorum:

During the metal stamping process, the size and shape accuracy of the metal stamping parts are guaranteed by the mold, which generally does not damage the surface quality of the stamping parts. Moreover, the service life of the mold is generally long, so the quality of metal stamping is stable.

2. Stamping metallis potest partibus cum ampliis dimensionibus et formis complexis procedere, sicut parvi stopwatches, trabes longitudinis automobilis, panelis etc. Due frigido deformatione et indurabilia materiae in medio stampionis metallorum, fortitudo et robusto stampionis metallorum utraque alta sunt.

3. Process metallici stampionis excelsa productivitate est, operatio convenienta, et facile est mechanizationem et automationem facere. Hoc est, quia stampio metallo dependet on stamping molds and stamping equipment to complete the processing. Punctus pulsae regulae duodecim vicibus per minutam attingere potest, et pressio velocitatis velocitatis gentibus aut etiam milibus vicibus per minutam attingere potest. Omnem pulsae pulsae potest punctum attingere.

4. Metallum pulsere generale non producit cipes aut solitudines, minores materia requirit, et alios calefactores non requirit. Therefore, it is a material saving and energy saving processing method, and the cost of metal stamping parts is low.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque