1. Punching inspection standards

1

1.2 Anguli acuti non explicite indicati in diagrammis (nisi aliud indicati) omnes R1.5 sunt.

1.3 Burres generated during stamping processing should have no obvious protrusions, indentations, roughness, scratches, rust or other defects on exposed surfaces such as door panels and panels.

1.4 Burra: Post punching, altitudo burra L5% t (t est altitudo plateae).

1.5 Scratches and cultro marks: It is qualified to touch with hands without scratching, and should be 0.1.

2. Bending inspection standards

2.1 Burra: Altitudo turbae extrudentis post bending est L10% t (t est densitate plateae). Ecce aliud specificatum est, angulum rotundum intra fixum R1 est.

2.2 Imprinting: visible creases, but not felt by hand (can be compared to the limit sample). 2.3 Lingua et dimensiones cum drawingibus consistent.

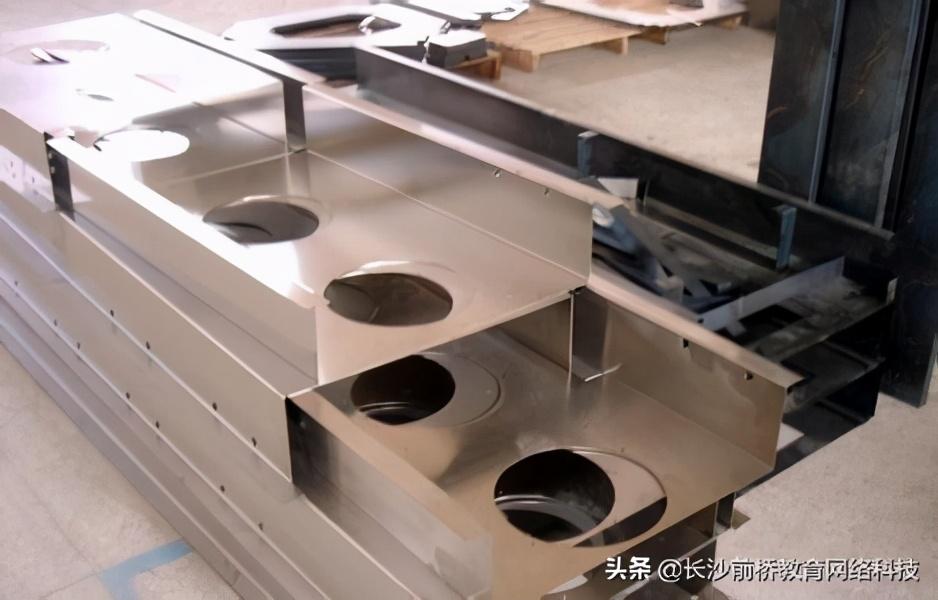

3. Inspection standards for Sheet Metal Processing parts

3.1 Riveting parts

After pressing on components such as rivet nuts (columnas), rivet screws, expansion rivet nuts (columnas), and pull rivet nuts, the threads non formformant (the nuts or screws can freely enter and exit without jamming). The rivet parts should be level with the plate surface et non permittit protrude or sink (the touch should be smooth). The rivet parts should be perpendicular to the plate surface, et nulla deformatione aut pig mouth phenomenum in flut area post presspressionem. Altitudine et pariusque altitudine pull pacis qua altitudine et altitudine quam altitudinis pacis pull pacis uniformum est.et non erit in summo incensum.

4. Welding

4 longitudo et altitudo plagae non excedet 10% longitudinis et altitudinis requirentis.

4.2 Coniuncta sollemnitatis: longitudo coniunctis sollemnitatis 8-12 mm esse, positio coniunctis sollemnitatis simetricalis esse, et positios superioris et inferioris unificabuntur. Si sunt opus speciales ad punctos in drawingibus processoris, sequere drawingibus.

4.3 Spot welding spacing should be less than 50mm, the diameter of the welding points should be less than 5, the welding points should be arranged evenly, the depth of the indentation on the welding points should not exceed 15% of the actual thickness of the plate, and there should be no obvious welding scars left after welding.

4

Postquam ferebatur, superficie exterioris partibus liberi sunt defectus, sicut inclusio, portis, pulveres, pulveres, depressiones, etc. defectus interioris superficie non oportet apparere et non efficiare ecclesiam. Unas importantes partes, such as door panels and panels, should also be subjected to post weld stress to prevent workpiece deformation.

4.6 External surface of welded parts should be ground flat. If it is a powder coated or electroplated part, the roughness after welding should be Ra3.2-6.3, and for painted parts, it should be Ra6.3-12.5.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque