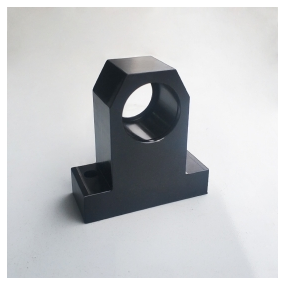

In the electronics industry, sheet metal chassis casings are often used to protect and protect internal components, while also considering their functionality and aesthetics. Below, Gu Ermei introduces several common surface treatment methods for sheet metal chassis casings.

1. Spray molding

Spray molding is one of the most widely used surface treatment methods for sheet metal chassis casings. Prima cogitatio spray molding est prohibere oxidationem chassis casing et multiplicare aestheticam suam.

2. Anodizatio

Anodizatio est procesus protektionis oxidium in metallis, quasi aluminium, titanium et magnesium formationis. Anodizing the shell of the sheet metal chassis can enhance its hardness and corrosion resistance, while also providing unique colors and textures.

Customization of chassis and cabinets

3. Drawing Wire

Diagramma wire refert to the process of processing metal surfaces into different textures through friction. The wire drawing process can provide a beautiful appearance and enhance the anti-slip and corrosion resistance of the sheet metal chassis shell.

Superiora sunt aliquid usus facie tractionis in processione casings metallis chassis. Each process has its unique characteristics and application scenarios, and we can choose the most suitable surface treatment method according to specific needs. Si oportet facere sciliculam cassis metallorum, liber sentite excambire exemplos~

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque