01

Processing equipment

1. Ordinary lathe:

Lathe prima est pro manipulatione fabricationis, discis, sculptilibus et alias opera cum superficie rotationibus, et est maxima utilis typus instrumenti machinae in fabricatione mechanicae. (Potet precision 0.01mm attingere)

2. Ordinary milling machine:

It can process flat surfaces, grooves, as well as various curved surfaces, gears, and more complex profiles. (Potet precision 0,05mm attingere)

3. Grinding machine

Grinder instrumentum machinae est qui faciem artificis pulsat. Grassiores maxima rotae velocitatis rotae rotationum rotationum ad grindum utilizant, quando alii instrumenti gravitationis, sicut olei, cineres abrasii, et abrasii liberi pro processione, sicut machinae ultra precision machinae, cineres abrasive, grinders, et machinas pulsatoris. (Potet precision 0,005mm attingere, parvi partes 0,002mm attingere potest)

4. Fitter

Operationes inter principes inter filios, speculatores, markos, fluctus, metientes, metientes et tritura, scrapientes, rigentes, rigentes, bending et fluentes.

5. CNC lathe

Mainly processing batch products, high-precision parts, etc. (Potet precision 0.01mm attingere)

6. CNC milling machine

Mainly processing batch products, high-precision parts, complex parts, large workpieces, etc. (Potet precision 0.01mm attingere)

7. Wire cutting

Elektrom lentem trabem aerum est, et mediam trabem molybdenum est. Lente fertilibus processionis alta precision et bona superficie splendor. Procede quaedam rupum precisium, grooves, etc. (Slow wire walking can achieve an accuracy of 0.003mm, while medium wire walking can achieve an accuracy of 0.02mm)

8. Spark machine

Electrical discharge machining (EDM) can process materials and complex shaped workpieces that are difficult to cut by ordinary cutting methods (such as groove corners, small holes, deformed holes, and hard alloys), without cutting force, and without defects such as burrs and tool marks. Not affected by material hardness or heat treatment conditions. (Potet precision 0,005mm attingere)

02

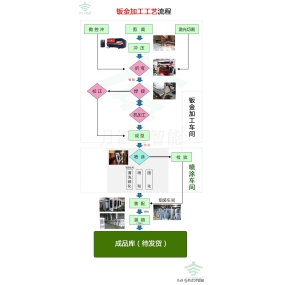

technological process

Specificatio procedentis machinationis unus est ex document is procedentibus qui procedura machinationis et modis operationis partium indicant. It is a process document written in a prescribed form under specific production conditions to guide production.

Procedus machinationis parterum ex multis proceduris compositus est, quorum unusquisque in pluribus instaurationibus, workstationibus, gradibus et secessionis potest dividere.

Procedores, quæ opus esse includiti in manufacturatione procedura, determinantur a complexitate structurae processionis partibus, necessitatibus machinationis accuracatis, et generis productionis.

Different quantitates productionis in diversis technicis processionis resultant.

Processus scientiam

1) Holas accurates minus quam 0,05 a militia CNC non potest machinare et machina CNC require; Si per foveam fuerit, etiam cauda secetur.

2) Cellas precisiis (per holas) post extinguendum praeparata sunt fertilibus inter processionem; Cultra pulchra machina difficile requirunt ante extinguendum et machinam precision post extinguendum. Non precision holas ante extinguendum potest facere (relinquens terminationem 0.2 in unam latere).

3) Slots with a width of less than 2mm require wire cutting, and even deep grooves with a depth of 3-4mm require wire cutting.

4) Minimum allowance for rough machining of quenched parts is 0.4, and the allowance for rough machining of non-quenched parts is 0.2.

5) Tenitudo coating is generale est 0.005-0.008, et secundum granditudinem antequam platitur.

03

Processo horas operantium

Tempus quota est tempus pro completione processi, et indicator labor is productivitates est. According to the time quota, production plans can be arranged, cost accounting can be carried out, equipment quantity and personnel staffing can be determined, and production area can be planned. Pro hoc quota temporis constituit regulas procedentis.

The time quota should be determined based on the production technology conditions of the enterprise, so that most workers can achieve it through hard work, some advanced workers can exceed it, and a few workers can achieve or approach the average advanced level through hard work.

With the continuous improvement of production technology conditions in enterprises, time quotas are regularly revised to maintain the average advanced level of quotas.

Tempus quota usus a combinatione personālum et operatorum procedentium determinatur per summarizationem praeterientium experientiam et referendum ad relevant informationes technical ad directum estimationem. Alternatively, it can be calculated by comparing and analyzing the time quota of workpieces or processes of similar products, or determined by measuring and analyzing the actual operating time.

=preparation hours+basic time

Tempus preparationis refert ad tempus consumptum ab laboribus ad cognoscere se cum documentis procedentibus, materialibus raw collect, fixturas installare, instrumentis machinae adjustare et fixturas disassemabilis. Methodus computationis: Estimata based on experience.

Tempus basis est tempus metallum extinguere.

04

Quotatio metodo calculationis costis

Processing cost=(material cost+processing cost) * 1.2

The coefficient of [1.2 includes management fees]

Equipment cost=(processing material cost+processing cost+purchase cost+assembly and debugging cost+design cost) * 1.2

The coefficient of [1.2 includes management fees]

Material cost=weight (density * volume) * unit price (yuan/kg)

Processing fee=process hours * unit price (yuan/hour)

Procuratio Iaponica (yuan)=pretium emere (yen)/exchange rate

The cost of domestic procurement products will be quoted by the supplier

Design fee=working hours * unit price (yuan/hour)

Informatio quotationis:

1) Lathe: 60 yuan/hour

2) Milling machine: 60 yuan/hour

3) Grinding machine: 60 yuan/hour

4) Fitter: 80 yuan/hour

5) Processing center: 60-120 yuan/hour

6) CNC lathe: 60-120 yuan/hour

7) Spark machine: 80-150 yuan/hour

8) Slow wire cutting: 60-150 yuan/hour; Prius initionis parvulorum est 80 yuan, cum magnis elementis, area 0.06-0.08 yuan/mm2 est

9) Fine hole discharge: carbon steel, tungsten steel, 1 yuan/mm for sizes up to and including 0.3, 2-3 yuan/mm for sizes below 0.3; ¥ 0.3 et supra 1.8-2 yuan/mm

10) Management fee: Costa price * 0.2

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole