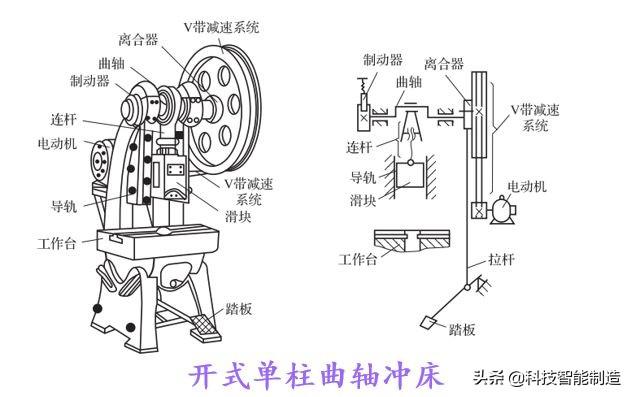

Using stamping equipment and dies to separate or deform metallic or non-metallic sheets, in order to obtain blanks or parts with a certain shape, size, and performance

1,

2,The basic process of stamping

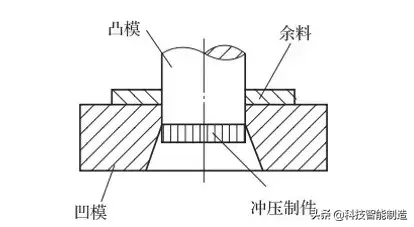

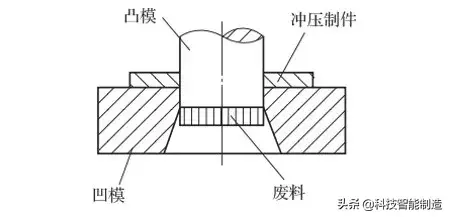

1. Blanca: Using a die to separate the sheet metal from the blank in a closed contour

Using punching to obtain a certain shape of the workpiece or billet

Separate the material inside the stamping blank with a closed contour to obtain perforated parts

2. Cutting: Separate parts or blanks from the sheet metal according to unclosed contour lines

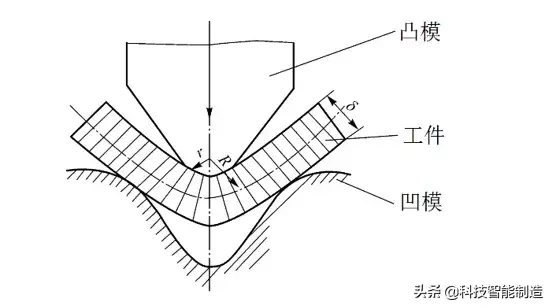

3. Bending: Bend the sheet or profile into a certain angle using a punching die

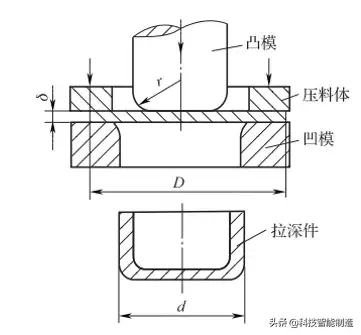

4. Graficum profundum

Forming the sheet metal into hollow parts while keeping the thickness basically unchanged

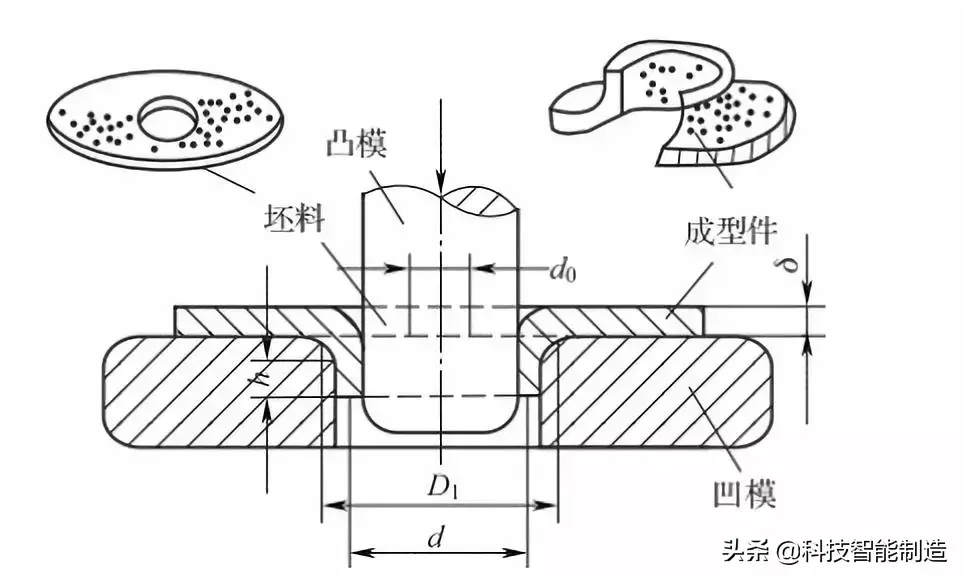

5. Flanging

Using the method of expanding holes on flat billets with holes, the plate is flipped into a straight edge along a certain curvature

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque