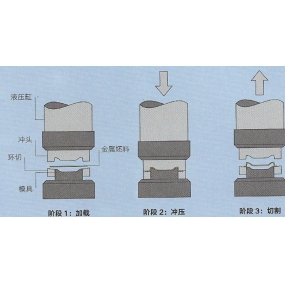

Customization by Emma Technology Co., Ltd. refers to the use of stamping technology to process and customize hardware according to customer needs and requirements. Stamping hardware is a common metal processing method, which uses stamping molds to process metal materials in the desired shape and size.

Customization of hardware stamping processing has the following characteristics:

1. Flexibilitate: Processum digitorum hardware secundum necessitates clientes customizatur, et potest diversas formas et dimensiones produktorum hardware, sicut lapides metallorum, fixturas metallorum, partibus metallorum, etc.

2. Efficiency: Hardware stamping processing uses molds for processing, which can achieve mass production, improve production efficiency and product quality.

3. High precision: Hardware stamping processing adopts professional stamping equipment and molds, which can achieve high-precision processing and ensure the accuracy of product size and shape.

4. Wide range of materials: Hardware stamping processing can process various metal materials, such as steel, aluminum, copper, stainless steel, etc., suitable for different industrial fields and application scenarios.

5. Low cost: The investment in hardware stamping processing equipment and molds is relatively low, which can achieve large-scale production and reduce production costs.

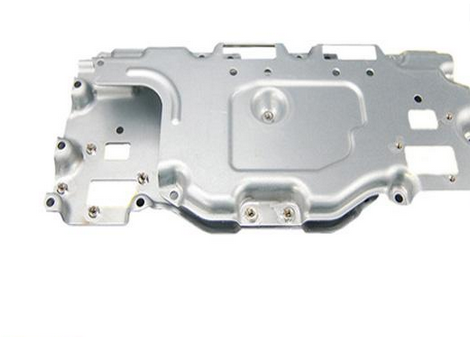

Hardware stamping customization is widely used in industries such as automobiles, electronics, home appliances, machinery, etc., and can meet the needs of different industries for hardware products. In the automotive industry, hardware stamping customization can be used to manufacture automotive components, such as body panels, seat frames, etc. In the electronics industry, hardware stamping customization can be used to manufacture the shells and structural components of electronic products. In the home appliance industry, hardware stamping customization can be used to manufacture the shells and accessories of home appliance products. In the mechanical industry, hardware stamping customization can be used to manufacture structural and connecting parts of mechanical equipment.

In breve, personalizatio hardware est flexibile, efficabile, et precisa procedentia, qua potest occurrere opus diversorum industriarum hardware produktorum et emissoribus produktis optimissimis qualitatis providere.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque