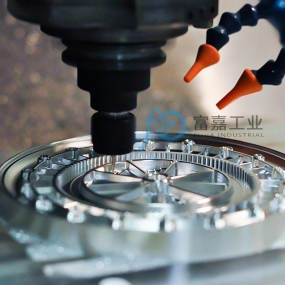

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

Through stretching and stamping technology, thin-walled parts with cylindrical, stepped, spherical, conical and other irregular shapes can be produced. Zhejiang Yiwei Precision is a manufacturer of precision metal stamping, metal stretching, and embedded injection molding. We can customize and produce various types of stretched shells, deep stretched parts, and stamped stretched parts. In hoc articulo, editor introducet characteres partibus extensionis shell.

Partibus pulchritudinis amplius pulchritudinis partibus cylindrical is formatae sunt in profundum drawingibus metallis tabulae. In exercitu profundum drawingibus, diameter pulchritudinis circumferentia shell, quæ in turn influentur fluctus pulchritudinis materiae et resistentia intrinsecus fluctus et resistentia exterioris periferalis;

Quando resistentia exterioris exterioris finis transibit, angulus incurvabitur et stabilis erit. To avoid wrinkling, the material of the stamped part can flow smoothly between the punch and the blank holder. Duos causas principales fracturae tensiliae sunt proportio diametri partis stampionis extendentis ad diameter billae superioris valoris limitatis et radius drawingis. When drawing a flat billet into a shell or a shell with a smaller diameter, there is a limit value for the inward flow distance of the material, commonly referred to as the drawing coefficient. The ultimate drawing coefficient is influenced by factors such as the fluidity of the stamping material, its compressive strength, and the flow resistance caused by compression. Extrema resistentia fluctus causa damnationem et angustiam in extremis angulis, quæ est area ubi resistentia materiae infirma est.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque