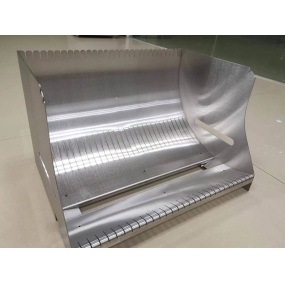

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

In the era of rapid technological updates, stamping companies need to continuously improve their existing production processes in order to better produce products that meet customer satisfaction, even exceed customer expectations, improve production efficiency, and have stronger market competitiveness. Below, we will introduce 7 things to pay attention to in metal stamping processing.

Processo

1. Valor termini oportet esse

Selection recta valorum angularum habet influentiam significantiam super qualitatem partium puncti precision. Usually, the higher the edge value, the better the accuracy, and the minimum should be selected while meeting the conditions of cutting surface quality.

2. Using precision molds for processing

When there are higher requirements for the cross-sectional quality and dimensional accuracy of the workpiece, precision stamping technology can be used.

3. Reasonable mold clearance

Parva clearance est principium pulchritudinis precision mortuum, et granditudo clearance et uniformitatis eius secundum extinguentem extinguentem directo effectum est qualitatem superficie pulchritudinis partee. The fine punching clearance is mainly determined by the thickness of the material, and is also related to the stamping profile and the material of the work piece. Interfusio nimis magna est, et materia deformation is regionis plus tensionem subiecta est, resultat in tensionem, quod est causa microcrackum et lacrimarum.

Appropriate backpressure

Back pressure is an important factor affecting the quality of precision machined parts. Excessive back pressure can increase the load on the punch and shorten the service life of the stamping die; Previce little back pressure can affect the dimensional accuracy, flatness, and shear surface quality of compressed parts. On the premise of ensuring the quality of stamped parts, it is necessary to adjust them to the lower limit as possible in the actual process.

5. Avoide lacrimandum opus

Utilizate fortitudinem vacuum tenentis et retrorsum pressionem ejectoris pinnis, et minimum punching gap utilizate, ut prohibetur lacrimandum materiae in fine nutritione procedentibus et deformationem plasticam garantiam.

6. The edge pressing force should be appropriate

In order to ensure the sound quality of compressed parts, reduce power consumption, and increase the service life of the mold, it is necessary to correct calculate and set the blank support force. Si fortitudo vacuum tenentis nimis parvus est, pressure static fluid is materiae in deformatione zona minima est, quod non est conducive ad stampionem. et erunt laci super superficiem tunicae quae influent qualitatem superficie tunicae Si fortitudo vacuum gripperi nimis magna fuerit, consummatio potentiae excessiva generat, conflicet structuram molae, et breviabit vitam servitutis molae.

7. Processing with precision punching machine

The fine feeding process requires the equipment to provide punching force, billet gripper force, and top plate force simultaneously, which is usually carried out in a dedicated press.

Zhejiang Yiwei Precision has 36 years of experience in stamping parts processing, metal stretching, and precision injection molding customization, supporting mold development and design. It can produce various automotive stamping parts, stamping stretching parts, embedded injection molding, precision injection molding parts, thinning stretching parts, and deep stretching parts. The company implements 5S on-site management, TPM equipment management, and has passed the IATF 16949 quality system certification. The manufacturing accuracy of 0.01mm products is welcome to customize with drawings and samples!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque