Intellectus qualitatem partium metallorum ad omnem industriam crucial est. But how should we measure it? Deeply delve ve and find a comprehensive answer.

Metodo mensurae qualitatem partium metallorum est verificare accuracionem partium stampionis, consistentiam singulorum partium, et si defectus sunt, sicut flamma aut mala.

Although the above content provides a quick answer, there is still much to understand the complexity of the quality of Metal Stamping parts. In illo profunda delubramus.

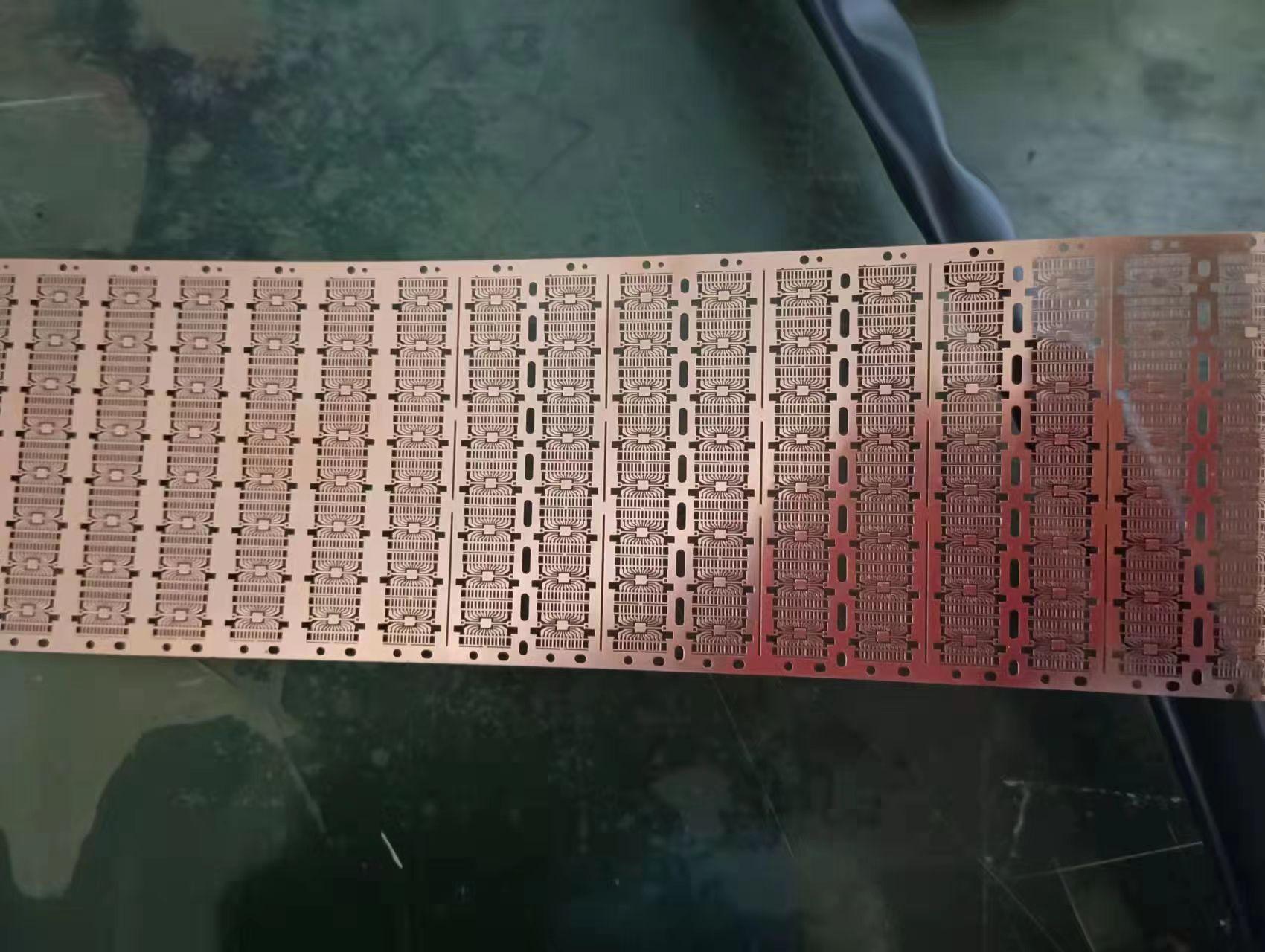

The core of understanding metal stamping is the manufacturing process of converting flat metal plates into specific shapes. Hoc per usum instrumentorum et molarum specializatorum effectum est qui altum pressionem faciunt ad deformationem et secant plateam metallim secundum design desideratum.

Secundo operationes interactiones, haec processus in diversis sortibus divisurus est, sicut punching, cutting, extrusion, bending, lingua cutting, rubicula pressing, et material fluctus. Each operation has its unique purpose, from punching holes in metal plates to raising them to create raised patterns (ribs).

Metallum pulchritudine magna significatur in diversis industriis. It is the cornerstone of industries such as automotive, electronics, aerospace and health care. Reage quare stampio metallo amplius utilizat est quia precisa, cito, et economica multa partes complexas producere potest. Utrum paneli corporis raedarum sunt, connectores in dispositivis electronicis, aut componentes in instrumentis domus, stampionis metallis crucial est in conversionem design in realitatem.

Essentially, metal stamping is not only a process, but also an art that combines engineering precision with material science to produce parts that power our daily lives.

Clave indicator qualitatis stampionis metallorum est secundum qualitatem stampionis metallorum, quod possit assecurare quod finis produktus conformetur ad especificationes expectatas et functiones expectatas facit. Sequentes sunt alii de principibus indicatoribus, de quibus professores curantur quando evaluantur qualitatem stampionis metallorum parterum:

Precisio parterum pulsere

Precisio est lapis angularis qualitatis partium metallorum. Accurata et errora partibus liberis stampis significant quod omnis parte produxit complicit in design specificationibus. Utrum in maquina aut parte in multitudine magna est, hoc precision assegurat quod parte perfecto aderit ad expectatum aplicationem. Any deviation, even a small one, can lead to malfunctions, reduce efficiency, and even safety hazards. Therefore, various industries invest heavily in advanced machines and skilled operators to achieve the highest level of accuracy.

Batch consistency

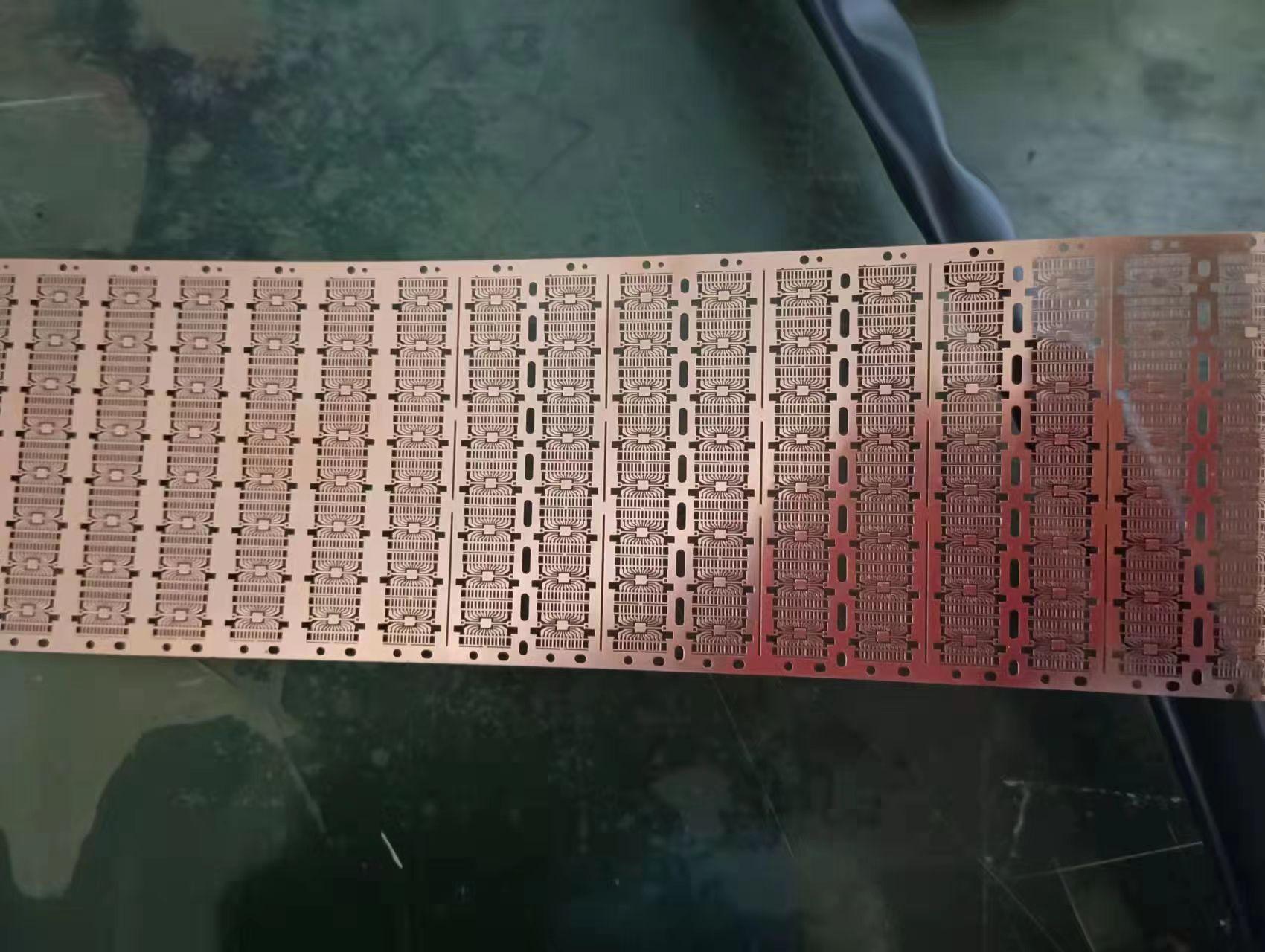

Quando individua precision partes commendabiles sunt, consistentiam in productione massae attingere est verum qualitatem certaminem. Consistentia secut ut omnem partem, ab initio usque ad novissimum in productione procedentibus, aeque altos standardes tenet. Haec consistentia crucial est, sublime in industriis, quales automobilis aut electronicae, qui milia partes identicae require. Inconsistent batches can lead to increased losses, rising costs, and potential product recalls, therefore consistency is an important quality indicator.

Nullus defectus

Defecti in partibus metallis, sicut ardores, malignantia, aut universae superficies, manifesta sunt errorum in productione.

Raedae rubra aut protrusiones non volebantur, saepe causae sunt operationibus. They can hinder the assembly process and even pose safety risks. Misalignment refert to the mismatch between parts and design intent, resulting in incorrect assembly. Superficie inequalitate potest causa a impropera operatione materiae aut problema in tempore stampionis. Absentia haec defecti clara indicator qualitatis est. It signifies a meticulous attention to detail, strict quality control measures, and the use of state-of-art machines.

In breve, haec clave indicatores closely monitorentur ut assegurantur ne solum perfecto functioni sunt, sed etiam fidelis et securis, adequas ad optimas suas.

The tools and techniques for measuring quality ensure that the quality of metal stamping parts is not only related to the final product, but also to the processes and tools used to achieve the product. To maintain the highest standards of metal stamping, it is necessary to combine advanced tools with powerful quality control technology.

Testing tools

Calipers: Calipers unus est de instrumentis maxima utilibus ad mensuram distanciae inter duos contra superficies objecti. sunt diversa typa caliperorum, inclusive vernier caliperos, caliperos dial, et caliperos digitales, unusquisque cum diverso nivello precision. Micrometrus: Comparat caliperos, micrometri accuracionem altior habent et parva mensura sunt. Micrometrus instrumentum scurrum utilit ut mensuraret dimensiones millesimam inchorum aut minorum. Gauge: Haec instrumenta specializata sunt, quas speciosa mensurae agentur. Exemplo, "; Normal/Abnormal "; The gauge checks the workpiece according to the allowable tolerance to ensure that the workpiece is not too large or too small. Alii typi instrumentorum mensurae, sicut anguli profundi aut anguli anuli, ad speciosa mensurae purposes utili sunt. Quality Control Technology

Statistical Process Control (SPC): Haec metodo technicas statisticas utilizat ut proceduram productionis monitoretur. Analizante datus exemplorum, SPC potest deviationes de proceduras standard ad corrigendum temporis identificare. Hoc modus activus est ut qualitatem stabilem asseguratur. Visual inspection: Aliquando oculus hominis optimus instrumentum est. Inspectores docti partibus videlice inspectabunt defectus, sicut flamma, discoloratio, aut mala. Quamquam haec metodo simplex videtur, saepe effectus est, subito cum aliis technologibus combinatus. Automatic quality inspection: With the advancement of technology, automated systems equipped with cameras and sensors can now detect parts at high speed. Haec systema celeriter defectum identificare potest, ut tantum alta qualitate partes sequenti stagi productionis intrare possunt. Using these tools and techniques in the metal stamping process, it can be ensured that each part meets the expected quality standards, thereby reducing loss, saving costs, and ensuring customer satisfaction.

The impact of quality on the final product: The quality of metal stamping parts is not only an indicator, but also a commitment to reliability, functionality and service life. When manufacturers prioritize quality, the final product benefits in multiple ways, directly affecting the user experience and the entire lifecycle of the product. The following is the impact of ensuring the quality of metal stamping on the final product:

Durabilitate: Exalta qualitate metallis stamping assegurat, ut singula parte ad maximum standards fabricatur, utilizat materiales rectos et prosessos. Haec modo produsae partes poterunt resistere portare, factores videntis et stresses mecanica. Exemplo, partibus metallis precisius in maquina perfecto fit, reddens unculum stressum super adjacentes componentes et extendens vitam produkti.

Functionalitatem: Procedus principis omnis produkti est expectata functionalitatem facere. Certificatione qualitatis stampionis metallorum assegurat ut omnes componentes precisa et precisa functionem suum faciant. Exemplo, connectores electricas accusatus in dispositivis optimis operati potest, permittant apparatum perfectum operare.

Aesthetics: Although the main focus of hardware stamping may be functionality and durability, aesthetics also plays a crucial role, especially in consumer facing products. High quality stamping technology ensures that product lines are simple, perfectly fitted, and as smooth as new. Exemplo, metallus pulsavit pro smartphone non solum apparatum protegit, sed etiam appellam visualem enhavit.

Costa efficientia: Investicio in qualitate expendita crescere videtur, sed in longo tempore expendit. Qualitatem altitudinis partibus potuerunt reddere necessitatem replacii, reparare et recumbere. Hoc non solum directos costas servat, sed etiam reputationem signorum protegit, ut servat fidem et fidelitatem.

Securitate: In industriis such as automotive or aerospace, the quality of metal stamping parts is directly related to safety. defectus in componente causam catastrophicam potest. Qualitatem assecuratio significat securitatem terminorum usatorum.

Environmental impact: Quality is also related to the environment. Produkti qualitatis altissimi longius vitae habent et necessitatem replacionis frequentiae reducunt. Hoc significat minus solitudinem, minus consummationem resursos, et minorem emissionem pedum carbon.

Conclusione: Metal stamping est lapis angularis fabricationis et actus est crucial in producentibus componentibus necessitatibus pro numero produktorum in vita nostra cotidie. Precisio, durabilitate, et functionalitate his componentibus directo influentur a qualitate procedentis stampionis. Ut locuti sumus, mensura et securitas qualitatem non solum probatio compliantiae est, sed promissio excellentiae, securitatis et sustinentiae development.

From the use of precision inspection tools such as calipers and micrometers to advanced quality control technologies such as statistical process control and automatic inspection, the industry has adopted numerous methods to adhere to the highest standards. These efforts not only ensure the optimal performance of the final product, but also improve its life span, aesthetics and safety.

In addition, the chain reaction of the quality of metal stamping parts is not limited to direct products. It can save costs, reduce environmental impact, and earn the continuation of confidence of consumers and stakeholders.

Essentially, the pursuit of quality in the metal stamping industry proves its commitment to providing the best products. Haec est procedus progressionis, innovation is, et firmae commitmenti ut certemus quod produkti, ex raedas usque ad minores instrumentos, ex eis optime possumus facere.

Intellectus qualitatem partium metallorum ad omnem industriam crucial est. But how should we measure it? Deeply delve ve and find a comprehensive answer.

Metodo mensurae qualitatem partium metallorum est verificare accuracionem partium stampionis, consistentiam singulorum partium, et si defectus sunt, sicut flamma aut mala.

Although the above content provides a quick answer, there is still much to understand the complexity of the quality of metal stamping parts. In illo profunda delubramus.

The core of understanding metal stamping is the manufacturing process of converting flat metal plates into specific shapes. Hoc per usum instrumentorum et molarum specializatorum effectum est qui altum pressionem faciunt ad deformationem et secant plateam metallim secundum design desideratum.

Secundo operationes interactiones, haec processus in diversis sortibus divisurus est, sicut punching, cutting, extrusion, bending, lingua cutting, rubicula pressing, et material fluctus. Each operation has its unique purpose, from punching holes in metal plates to raising them to create raised patterns (ribs).

Metallum pulchritudine magna significatur in diversis industriis. It is the cornerstone of industries such as automotive, electronics, aerospace and health care. Reage quare stampio metallo amplius utilizat est quia precisa, cito, et economica multa partes complexas producere potest. Utrum paneli corporis raedarum sunt, connectores in dispositivis electronicis, aut componentes in instrumentis domus, stampionis metallis crucial est in conversionem design in realitatem.

Essentially, metal stamping is not only a process, but also an art that combines engineering precision with material science to produce parts that power our daily lives.

Clave indicator qualitatis stampionis metallorum est secundum qualitatem stampionis metallorum, quod possit assecurare quod finis produktus conformetur ad especificationes expectatas et functiones expectatas facit. Sequentes sunt alii de principibus indicatoribus, de quibus professores curantur quando evaluantur qualitatem stampionis metallorum parterum:

Precisio parterum pulsere

Precisio est lapis angularis qualitatis partium metallorum. Accurata et errora partibus liberis stampis significant quod omnis parte produxit complicit in design specificationibus. Utrum in maquina aut parte in multitudine magna est, hoc precision assegurat quod parte perfecto aderit ad expectatum aplicationem. Any deviation, even a small one, can lead to malfunctions, reduce efficiency, and even safety hazards. Therefore, various industries invest heavily in advanced machines and skilled operators to achieve the highest level of accuracy.

Batch consistency

Quando individua precision partes commendabiles sunt, consistentiam in productione massae attingere est verum qualitatem certaminem. Consistentia secut ut omnem partem, ab initio usque ad novissimum in productione procedentibus, aeque altos standardes tenet. Haec consistentia crucial est, sublime in industriis, quales automobilis aut electronicae, qui milia partes identicae require. Inconsistent batches can lead to increased losses, rising costs, and potential product recalls, therefore consistency is an important quality indicator.

Nullus defectus

Defecti in partibus metallis, sicut ardores, malignantia, aut universae superficies, manifesta sunt errorum in productione.

Raedae rubra aut protrusiones non volebantur, saepe causae sunt operationibus. They can hinder the assembly process and even pose safety risks. Misalignment refert to the mismatch between parts and design intent, resulting in incorrect assembly. Superficie inequalitate potest causa a impropera operatione materiae aut problema in tempore stampionis. Absentia haec defecti clara indicator qualitatis est. It signifies a meticulous attention to detail, strict quality control measures, and the use of state-of-art machines.

In breve, haec clave indicatores closely monitorentur ut assegurantur ne solum perfecto functioni sunt, sed etiam fidelis et securis, adequas ad optimas suas.

The tools and techniques for measuring quality ensure that the quality of metal stamping parts is not only related to the final product, but also to the processes and tools used to achieve the product. To maintain the highest standards of metal stamping, it is necessary to combine advanced tools with powerful quality control technology.

Testing tools

Calipers: Calipers unus est de instrumentis maxima utilibus ad mensuram distanciae inter duos contra superficies objecti. sunt diversa typa caliperorum, inclusive vernier caliperos, caliperos dial, et caliperos digitales, unusquisque cum diverso nivello precision. Micrometrus: Comparat caliperos, micrometri accuracionem altior habent et parva mensura sunt. Micrometrus instrumentum scurrum utilit ut mensuraret dimensiones millesimam inchorum aut minorum. Gauge: Haec instrumenta specializata sunt, quas speciosa mensurae agentur. Exemplo, "; Normal/Abnormal "; The gauge checks the workpiece according to the allowable tolerance to ensure that the workpiece is not too large or too small. Alii typi instrumentorum mensurae, sicut anguli profundi aut anguli anuli, ad speciosa mensurae purposes utili sunt. Quality Control Technology

Statistical Process Control (SPC): Haec metodo technicas statisticas utilizat ut proceduram productionis monitoretur. Analizante datus exemplorum, SPC potest deviationes de proceduras standard ad corrigendum temporis identificare. Hoc modus activus est ut qualitatem stabilem asseguratur. Visual inspection: Aliquando oculus hominis optimus instrumentum est. Inspectores docti partibus videlice inspectabunt defectus, sicut flamma, discoloratio, aut mala. Quamquam haec metodo simplex videtur, saepe effectus est, subito cum aliis technologibus combinatus. Automatic quality inspection: With the advancement of technology, automated systems equipped with cameras and sensors can now detect parts at high speed. Haec systema celeriter defectum identificare potest, ut tantum alta qualitate partes sequenti stagi productionis intrare possunt. Using these tools and techniques in the metal stamping process, it can be ensured that each part meets the expected quality standards, thereby reducing loss, saving costs, and ensuring customer satisfaction.

The impact of quality on the final product: The quality of metal stamping parts is not only an indicator, but also a commitment to reliability, functionality and service life. When manufacturers prioritize quality, the final product benefits in multiple ways, directly affecting the user experience and the entire lifecycle of the product. The following is the impact of ensuring the quality of metal stamping on the final product:

Durabilitate: Exalta qualitate metallis stamping assegurat, ut singula parte ad maximum standards fabricatur, utilizat materiales rectos et prosessos. Haec modo produsae partes poterunt resistere portare, factores videntis et stresses mecanica. Exemplo, partibus metallis precisius in maquina perfecto fit, reddens unculum stressum super adjacentes componentes et extendens vitam produkti.

Functionalitatem: Procedus principis omnis produkti est expectata functionalitatem facere. Certificatione qualitatis stampionis metallorum assegurat ut omnes componentes precisa et precisa functionem suum faciant. Exemplo, connectores electricas accusatus in dispositivis optimis operati potest, permittant apparatum perfectum operare.

Aesthetics: Although the main focus of hardware stamping may be functionality and durability, aesthetics also plays a crucial role, especially in consumer facing products. High quality stamping technology ensures that product lines are simple, perfectly fitted, and as smooth as new. Exemplo, metallus pulsavit pro smartphone non solum apparatum protegit, sed etiam appellam visualem enhavit.

Costa efficientia: Investicio in qualitate expendita crescere videtur, sed in longo tempore expendit. Qualitatem altitudinis partibus potuerunt reddere necessitatem replacii, reparare et recumbere. Hoc non solum directos costas servat, sed etiam reputationem signorum protegit, ut servat fidem et fidelitatem.

Securitate: In industriis such as automotive or aerospace, the quality of metal stamping parts is directly related to safety. defectus in componente causam catastrophicam potest. Qualitatem assecuratio significat securitatem terminorum usatorum.

Environmental impact: Quality is also related to the environment. Produkti qualitatis altissimi longius vitae habent et necessitatem replacionis frequentiae reducunt. Hoc significat minus solitudinem, minus consummationem resursos, et minorem emissionem pedum carbon.

Conclusione: Metal stamping est lapis angularis fabricationis et actus est crucial in producentibus componentibus necessitatibus pro numero produktorum in vita nostra cotidie. Precisio, durabilitate, et functionalitate his componentibus directo influentur a qualitate procedentis stampionis. Ut locuti sumus, mensura et securitas qualitatem non solum probatio compliantiae est, sed promissio excellentiae, securitatis et sustinentiae development.

From the use of precision inspection tools such as calipers and micrometers to advanced quality control technologies such as statistical process control and automatic inspection, the industry has adopted numerous methods to adhere to the highest standards. These efforts not only ensure the optimal performance of the final product, but also improve its life span, aesthetics and safety.

In addition, the chain reaction of the quality of metal stamping parts is not limited to direct products. It can save costs, reduce environmental impact, and earn the continuation of confidence of consumers and stakeholders.

Essentially, the pursuit of quality in the metal stamping industry proves its commitment to providing the best products. Haec est procedus progressionis, innovation is, et firmae commitmenti ut certemus quod produkti, ex raedas usque ad minores instrumentos, ex eis optime possumus facere.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque