Quanto scis de tecnologia industrial design? Metal Stamping and cold stamping technology are generally used to process metal sheets in shallow concave shapes or curved profiles. Ei habet characteres velocitatis processionis et altae precision. It can be used to produce a variety of daily products, from cars to metal pallets.

High processing cost, high mold cost, low to medium unit cost

Typical Applications: Automotive, Consumer Products, Furniture

Applicability · Large scale production

Qualitatem procedentem

Related processes: Deep drawing, Metal spinning, Bending forming

Circulus procedens · Circulus curtus (1 secunda usque 1 minuta)

Process Introduction: Metal stamping is a metal processing method that is based on the plastic deformation of metal. It uses molds and stamping equipment to apply pressure to the sheet metal, causing plastic deformation or separation of the sheet metal, thereby obtaining parts (stamped parts) with certain shapes, sizes, and properties. Stamping technology plays an important role in the manufacturing process of automobile bodies.

Metal stamping potest ut faciat formas metalicas concaves dissolutas, et opus processionis mollis relative altae sunt, et hoc processus est solum adequatus pro produktio magna scala. Haec processus est alta precision in processione et non est substantia variatio in densitate materiae. Quando proportio inter profundum et diametrum diminuit, processus machinatorium similis est valde profundum drawingibus, nec ex hoc procedentibus machinatorium diminuit profundum materiae.

Mass production of parts requires the comprehensive use of multiple forming and cutting processes based on progressive tools. Seria mollium in rapido processione essent. In processo partium machinationis, aliquando secundum operationem necessarium est in ex previa formata partibus. Aliquid partes quinque aut plures operationes opus possunt, quae numerum interactorum reflect. Haec processus lapides metallos in formas cylindricas, conicas et semifericas procedere potest. The frequent combination of stamping and pressing in the process provides a wide range of options for the entire design, such as when machining flange edges, asymmetric hubs, and shapes with perforations, the distinctive features of this process are evident.

Technical Description

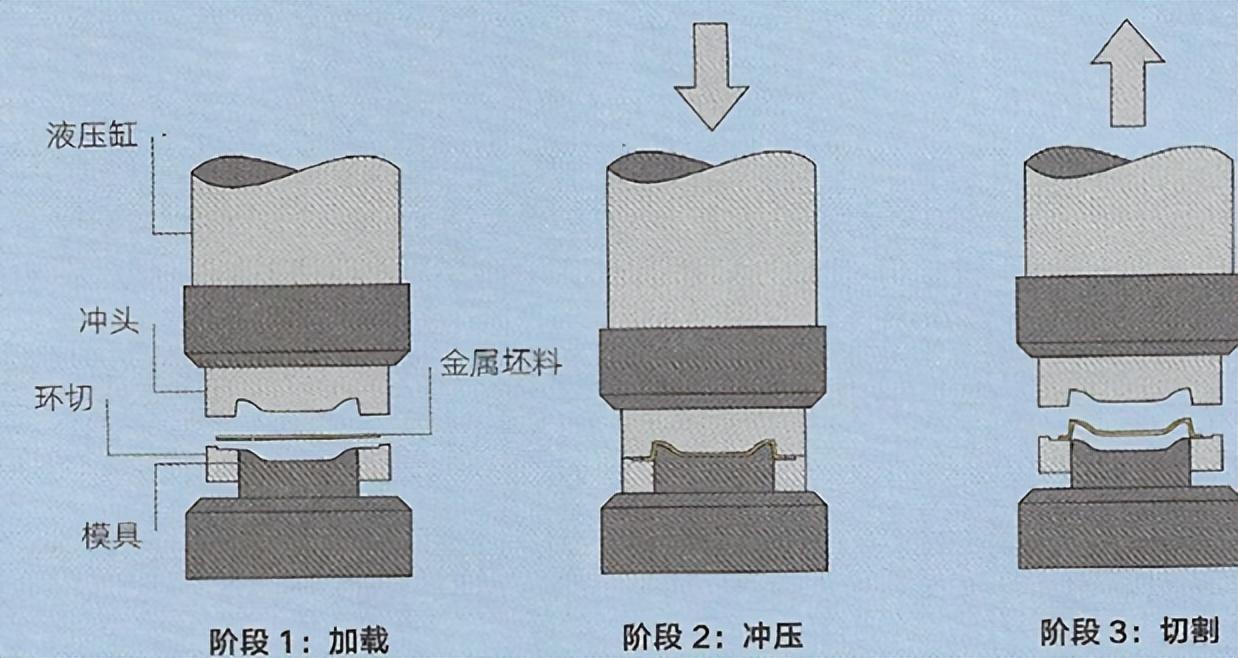

Procedus metallis stampionis in pulso puncho est transferre potestatem ad punchom per cylindrum hydraulicam aut apparatum mechanicum (sicut press cam). Generally, hydraulic cylinders are chosen because their pressure is evenly distributed throughout the entire stamping cycle, and those using mechanical devices also have a place in the metal processing industry.

Punches and molds are specialized and generally perform a single operation of forming or punching. In operibus, billae metalicae normale in taberna opus cargae sunt. Then clamp the punch and complete the forming process of the part in one stroke.

Post consummationem molationis ascendet et eiciet partem, in qua parte auferetur. Aliquando part is formatio est continuus processus, et post processionem, etiam transibit in processum stampionis. Hoc saepe cognoscitur quasi continuum fermentum.

Under these processing conditions, the processed metal parts are transferred to the next stage of processing. Haec processus manum aut per transferendum tracarum facere potest. Multi systemae automaticas sunt et altas procedentiae velocitates tenent. Proximus gradus potest inducere pressionem, stampionem, curritionem, aut alteram processionem secundariam.

Aplicatio tipica stampionis processionis maxima est. In industria automobilis magna multitudo technique processionis metallorum magna pulsantur aut extruxerunt, inclusive corpus, ostium linium et eductum.

Haec processus pro manipulatione corporum metallorum photographicum, telephonorum mobilum, televisionis casings, domus apparatum et MP3 ludentium utilitur. Culina et officio vasa, instrumenta, et cultri etiam hoc processum utilizat. Forma externa et struktura interiora parterum procedere potest utilis hoc processum.

Small batch production of parts using related processes is achieved through sheet metal processing, metal spinning, or bending forming. Haec procedentia similis similis sculptilibus metallis producere potest, sed praesentias magnas laboris requirant.

Quamquam parantes et profundos disegnantes similes sunt, adhuc differentia significantia sunt. Quando altitudo part is maior est quam 1/2 diametri, pars longitudo est, et murum densitudo diminuta est. Hoc graduum et lentem operationem opus est ut non excessive extensionem et lacrimam materiae evaderet.

Superplastic molding can produce larger and deeper parts using simple operations. However, this procession is limited to aluminum, magnesium and titanium because it requires the material to have superplasticity.

Profilus metallis in processione qualitate ductilitatem et fortitudinem metallorum parterum coniunxit, crescere rigiditatem et splendorem.

Si praecepta superficie effectorum non sunt particular stricta, tantum partes post deformationem modicum debuere oportet. Sandblasting ad diminundum superficiem gravitatem est. Partes etiam per pulverem vestimentum, pinturam aspersionem aut electroplatinam procedere possunt.

Design opportunities referunt to the methods of quickly and accurately manufacturing shallow concave shapes using sheet metal. Haec technica ad circulos, quadratos et polygonos utilizatur.

Partibus tuis obstructis potest confortari additione funibus, qui etiam potest diminuere pondus et processione costas. Selecting appropriate molds can process profiles with composite curves and complex surfaces. Similis procesus ut hoc opus completurum faciendum metallicum est, sed opus scientiae magnis opus est. Fascipes molae ad fabricationem metallorum et stampionem metallorum applicantur. Una later hoc molae ex ligno rigide facta est, qui sufficit pressionem ad formandum metalla vacuum in puncto.

Design considerations: Stamping processing is carried out on a vertical axis. igitur angulo concave in secundo pulso formatur. Secondary stamping includes pressure deformation, cutting extension, and curling.

Prima operatio stampionis tantum dimittere potest diameter materiae defecti 30%. Continuous operation can reduce the diameter by 20%. Hoc significat, quod processionem aliorum parterum quasi numerum constantem stampionis requirit.

In tecnologia gravitationis profunda, procedus saepe limitatus est a machina capacitate machinae. Dimensio lecti machinae granditudinis billeti determinat, et stroca longitudinis extensionis determinat. Circulus processionis a stroco et complexitate parterum determinatus est.

Densita steelae claudicationis a 0,4 usque 2mm varia est, et possit usque ad 6mm claudicatores debiles procedere, sed ex forma influentur.

Multi lapides metallis per hanc processi poterunt, sicut ferrum carbonum, steelam sterilis, aluminium, magnesium, fialam, coper, aes et cincum.

Costa processionis relativa alta est propter necessitatem molda metalla alta fortitudinis in processione. Half rigid ruber fabrica minima sunt, sed adhuc instrumenta metalla singula latera requirunt et solum ad parva productionem adequata sunt.

Circulus processionis brevissimus est, et 1 usque 100 partes intra 1 minutum procedere potest. Replacio et configurato mollium quantum tempore necesse est.

Costa labor is relativa minima est propter altum gradum automaticae. Polonia producet laborem multo.

Omnia materia deserta recycletur a causa inflationis medio. Tecnologia metalla stampionis utilisar potest ad producendum elementos durabiles.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque