Summary of Mechanical Processing Procedures and Price Estimation

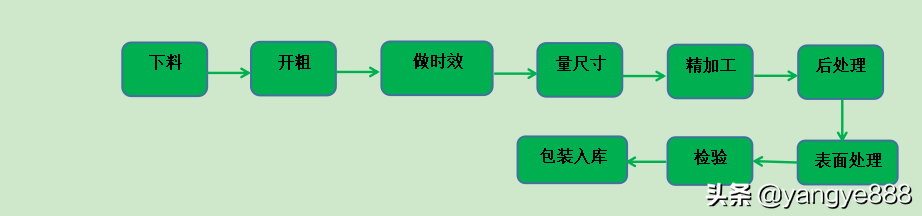

1,Mechanical processing procedures:

1) Cutting: Use a sawing machine to cut the corresponding material into the approximate size of the parts that need to be processed. (Usually leave a margin of 5-8 mm in length and width)

2) Cutting difficile: Use lathes, milling machines, wire cutting and other equipment to process the approximate shape of the parts required by the drawing, removing most of the blank allowance.

3) Timeliness: Timeliness in naturam temporalitatem et artificiam temporalitatem divisa est. Natural aging refers to allowing the workpiece to stand for 24 hours or longer, while artificial aging refers to heat treatment of the workpiece in a high-temperature box or box furnace. The purpose of time efficiency is to eliminate stress and reduce deformation of the workpiece during precision milling process.

4) Dimensiones mensurae: Postquam processus senectionis consummatis est, factus est laboris aliquid gradus deformation is et mensus est ut determinaret reliquum mensuram.

5) Precision machining: Strictly follow the dimensions required by the drawing to carry out precision machining to meet the workpiece dimensions required by the drawing. For workpieces with high precision requirements, semi precision machining processes will be arranged as needed before precision machining.

6) Post processionem: Haec processus in priorem processum insertabitur secundum diversas sortes parterum.

1. Fitter: including chiseling, sawing, filing, straightening, drilling, threading, deburring, chamfering, and screwing of works.

2. Machina gravitationis: Quando alta precision est pro circulo exterior, intrinsecus caudam, finem faciem, etc. opus est relinquere marjinam post proceduram machinitatis precision is et machinam gravitationis ad grindum.

3. Maquina Boring: For holes with high requirements for size, shape, and positional accuracy, use a boring machine for machining.

4. Flaw detection: Surface flaw detection is required for standard screw parts and welded parts to ensure the strength of the workpiece.

7) Surface treatment: After the processing of the workpiece is completed, surface treatments such as ordinary oxidation, pulse anodizing, hard oxidation, passivation, sandblasting, painting, etc. need to be applied to the workpiece surface to achieve the effect of aesthetic and oxidation prevention.

8) Inspection: It is necessary to inspect the surface treated workpiece, including various dimensions, colors and other key information, to ensure compliance with the drawing requirements.

9) Packaging and storage: Packaging the qualified workpieces and storing them together with certificates of conformity, inspection reports and other documents.

2,Composition of quotation for machined workpieces

1) Materials: Calculate material costs based on the density and price of materials required for different workpieces. (ρ=m/v)

2) Horae opus: prima horas operation is manus et horas operationis, pretium calculatur based on personnel hourly wages and equipment hourly fees multiplied by program running time. (Programmatio)

3) Pecunia operationis superficiis: Calculate the price based on the different surface treatment processes required by the workpiece drawing.

4) Profit: Based on the company's operation and scale, calculate the profit quotation proportionally on the aforementioned price basis.

5) Tax: Calculate taxas based on the invoicing format and tax points required by the country.

6) Transportatio: Corresponding fees will be charged based on different transportation methods. (Exemplis freight air, logistics, express delivery, etc.)

3,Processus labor hours

Time required to complete a process, process hours=preparation hours+basic time

Tempus preparationis referit ad tempus consumptum a laboribus ad cognoscere se cum documentis procedentibus, vacuum colligere, fixturas installare, instrumentis machinae adjustare, nullis positiones alignere et fixturas disassemabiles.

Tempus principalis est tempus quam opus est procedere programmam procedentis.

4,Quotation cost estimation method (this method is applicable to mass-produced products for reference)

Processing cost=(material cost+processing fee) * 1.2~1.5 (including management fee, sample and small batch factors * 3~5)

Material cost=weight (density * volume) * unit price (yuan/kg)

Processing fee=process hours * unit price (yuan/hour)

5. Preces aluminium et steelam communes:

7075T6: Rod and Plate

Parva fabrica: circa 38 yuan/kg

Enterprise military standard: 96-100 yuan/kg

1. Dongqing Aluminum Industry:

Standard National: 45-48 yuan/kg

National military standard: 78-80 yuan/kg

2. Southwest Aluminum Industry:

Standard nacionalis: 52-60 yuan/kg

National military standard: 100+yuan/kg

paper size

1. Dongqing Aluminum Industry:

Standard National: 40-45 yuan/kg

National military standard: 70-75 yuan/kg

2. Southwest Aluminum Industry:

Standard nacionalis: 52-60 yuan/kg

National military standard: 100+yuan/kg

Tabulae 7075: circa 75-80 yuan/kg; (Customization required, minimum order of 300kg)

2A12 pipes are 10-20 yuan/kg more expensive than bars and plates

6061 virgas et plateas: circa 30 yuan/kg

6063 virgas et plateas: circa 24-28 yuan/kg

7075 T7351/T7451: Around 80 yuan/kg

7050: Around 85 yuan/kg

Stella material:

45 #, Q235: The current average price is around 7.5 yuan/kg.

304 virgas et tabulae: circa 30 yuan/kg. Ex 20 yuan/kg ante annos

05cr17ni4: standard nacionalis: circa 55 yuan/kg; National military standard: around 120 yuan/kg

30CrMnsiA: Standard National: circa 35 yuan/kg; National military standard: around 80 yuan/kg

1cr18ni9:26 yuan/kg o so

Pom (black, non flame retardant): around 15/kg

Brass: circa 60/kg

6,Quotatio ad usum apparatum processionis:

1) Ordinary lathe: 35-45 yuan/hour

2) CNC lathe: around 80 yuan/hour

3) 3-axis machining center: circa 60-120 yuan/hour;

4) 4-axis machining center: around 150 yuan/hour; Prius batch of 120 yuan/hour

5) 5-axis machining center: 300-500 yuan/hour

6) Grinding machine: 60 yuan/hour

7) Milling machine: 60 yuan/hour

8) Spark machine: 80~150 yuan/hour

9) Slow walking silk: 60-150 yuan/hour

10) Fitter: 80/hour

7,Common surface treatment prices:

1) Ben, white oxidation: about 3 yuan/decimeter ²

2) Black oxidation: around 4 yuan/decimeter ²

3) Hard sulfuric acid anodizing: around 5 yuan/decimeter ²

4) Passivation: around 5 yuan/decimeter ²

5) Anodizatio pulsa: circa 7.5 yuan/decimeter ²; Per parte: Parva elementa 5-10 yuan/piece

6) Sandblasting: around 1 yuan/decimeter ²

7) Pictura Spray: pictura normala spray (absque pulsatione aut punctio scrapit): circa 1 yuan/decimeter ²

Normal process painting: 3-3.5 yuan/decimeter ²

8) Nickel plating (chemical): 1.2 yuan/decimeter ²

9) Galvanized (white): 2-3 yuan/kg (workpiece weight)

8, 3D printing fee model

Usually charged based on the weight of the materials used (yuan/g) (additional charges may apply if other treatments are required)

Preces referentiae materiae usus sicut sunt:

9,Welding:

1) Vigilum ferrum ferrum ferrum ferrum ferrum est: sublime inter ferrum et ferrum ferrum, scalam oxideum super superficiem virgae fertilis utilizatur ad isolatum aerum et protegam ferrum.

2) Double protection welding: using carbon dioxide as a protective gas to protect the weld bead, with a thick weld layer.

3) Argon arc a ferentia: Metodo ferentis maximus utilizatus, qui gas argon in petram protectilem utilizat ut protegeret planum. Temperatura ferentia alta est, et layer ferentis tenens et firma est. Utilis est ad ferendum acidam, aluminium et titanium.

4) Laser welding: Laser high-temperature dissolution welding wire, with weak firmness, mainly used for welding decorative parts.

5) Vacuum welding: Welding is carried out in a vacuum environment using argon arc welding to ensure that the weld bead and workpiece are isolated from air and the welding is reliable. Methodus principis titanium ferentibus.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque