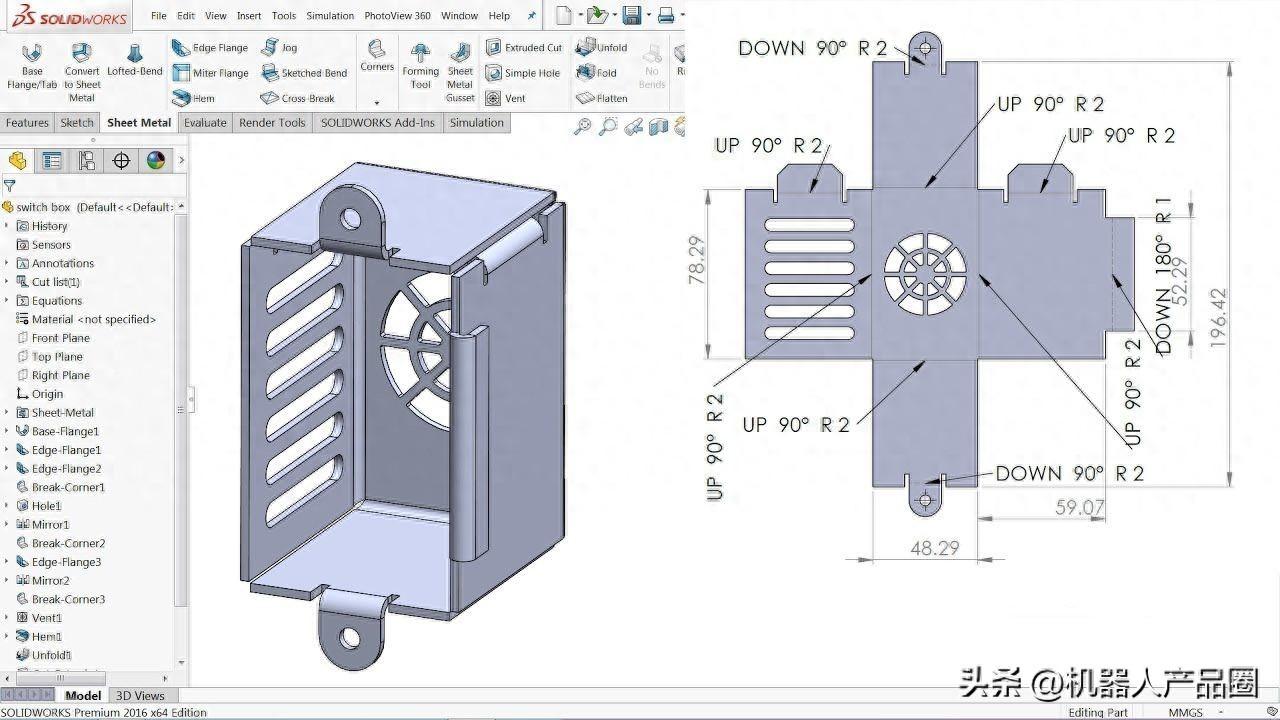

Sheet Metal Processing involves various types, mainly including laser cutting, water jet cutting, plasma cutting and other processes used for material separation, as well as bending, punching, shearing and other processes used for material forming. In addition, there are other processing methods such as curling, ironing and hydraulic forming. Selecting the type of processing, product requirements and material characteristics need to be considered. Welding, riveting and other processes can also be used during the processing to meet the structural and connection requirements, ensuring the quality and functionality of sheet metal parts. Hic tres generis usus introducamus

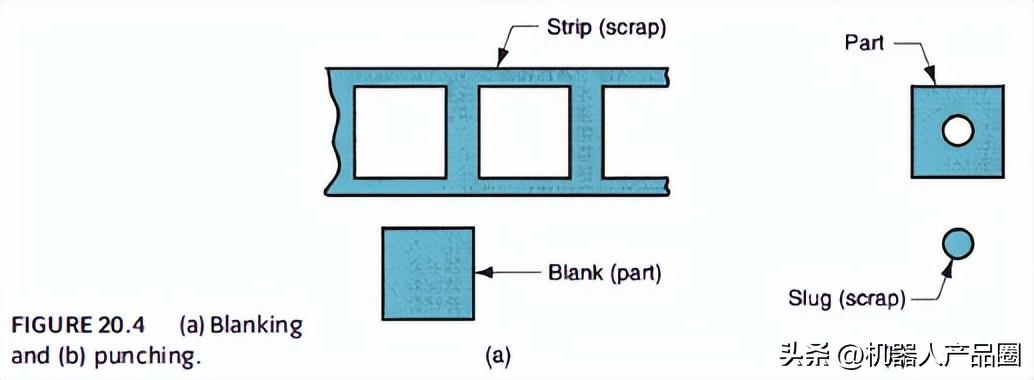

1,Cutting

a. Cut: Cut operation along the straight line between two cutting edges

b. Punching: A one-step cutting operation along a closed contour to produce the required parts

c. Stamping: Cutting operation along a closed contour, where the remaining inventory is parts

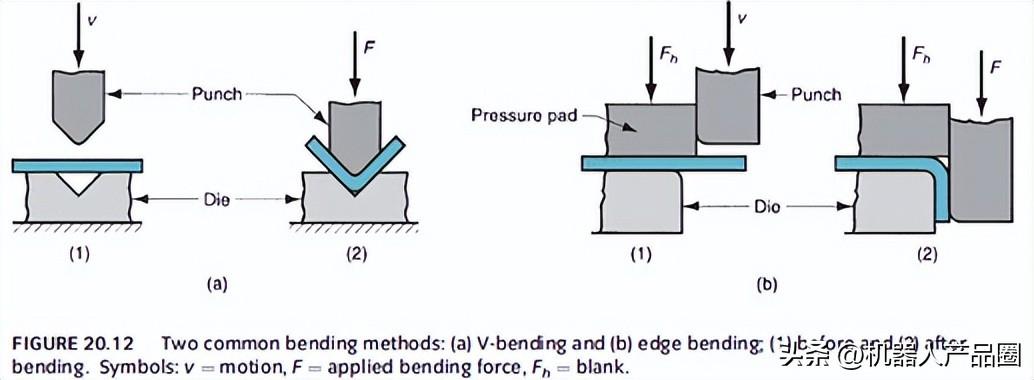

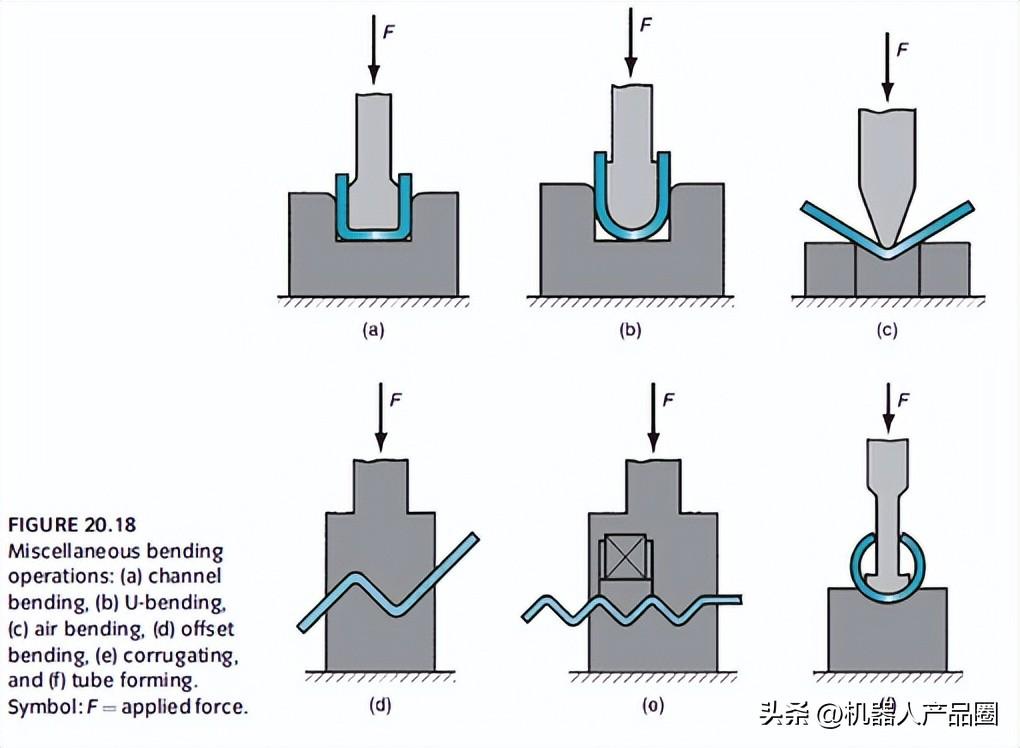

2 , Bending

Densita lapidis metallis quae deformationem plasticam subportat per deformationem circum axim rectam quasi non modificatum est

Other bending/forming operations

1. Flanging: straight, stretch, shrink

2. Curritio: In multiplibus gradibus bending, angulum tabuli crescet ut cresceret rigiditatem et melior aspectum

3. Seam: Similar to rolled edges, but assembled with two plates metallic edges

4. Curritio: Formatio lateribus partee in formam rotatum aut curratum facit securitatem, fortitudinem et aestheticam

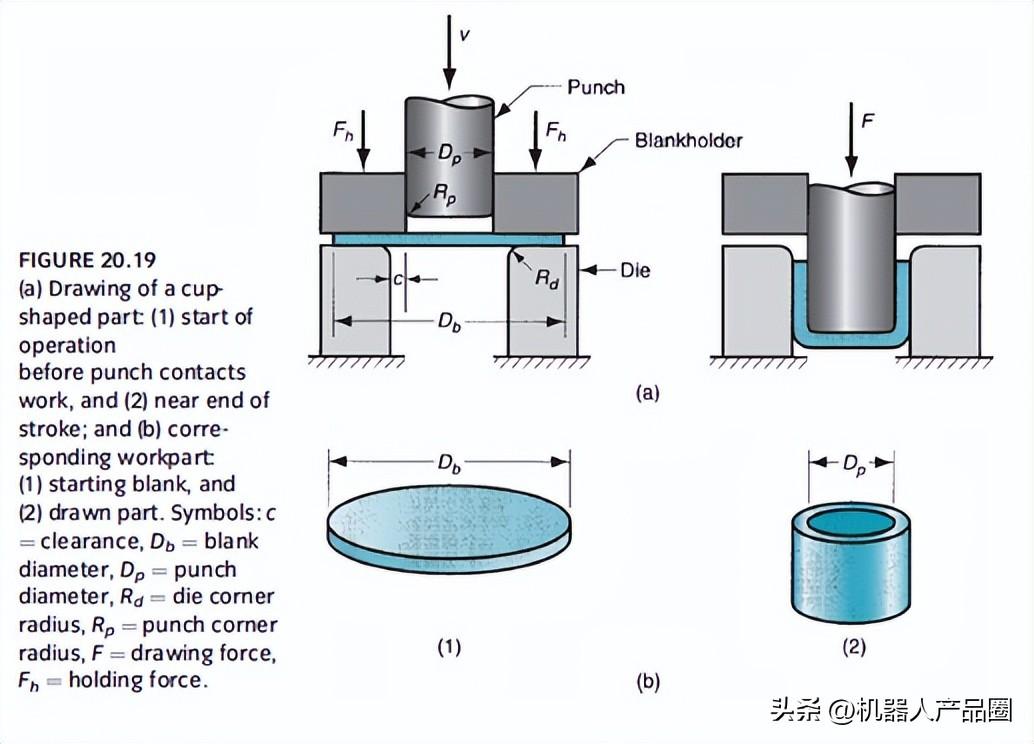

3,Stretching

Metal sheet forming process used for manufacturing cup-shaped, box shaped, or other complex curved and concave parts, commonly used parts: beverage cans, ammunition shells, sinks, cookware, automotive body panels

Si forma commutata pro parte design est nimis grava, perfecta formatio partee potest requirere multiplices gradus extensionis, cognoscata est quasi extra gradus extensionis. Intenium anuli anguli pressionis est prohibere pulchritudinem flange, lacrimandum, aurem et superficiem in calice pullandum.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque