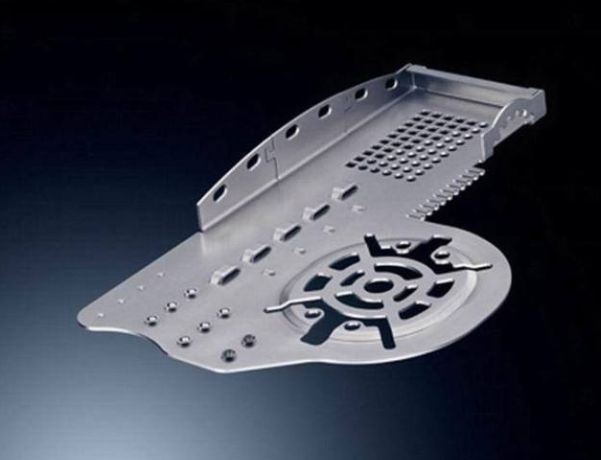

The process process of the Sheet Metal Processing process refers to the entire process of gradually changing the shape, size, size, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, HabyH, Quid?

Specificationes procedentium in processione metalla folii

The process flow specifies the machining process of the parts, while the specific machining content is guided and controlled by the process specification.

Process specification is a technically feasible and economically reasonable process plan selected by process technicians based on the requirements of product drawings, the characteristics of the workpiece, production batch, and the existing equipment and production capacity of the enterprise. After careful comprehensive analysis and comparison of several possible process plans, it is a technical document that guides the production process of parts. In documento technico vacuum pro parte, method processionis eius, et dimensiones processionis specificas sunt; Natura, quantitate, sequence, et qualitate requies singulorum procedentium; Modelles Equipmentorum et speciacis per singulos procedentibus utili sunt; Formus instrumentorum processionis (sicut instrumentos auxiliarum, instrumentos, moldes, etc.) in omni processo utilis; Classificationes qualitatis, metodes inspectionis, et necessitates pro omni processo.

Generally speaking, when it comes to the processing technology of all sheet metal parts, it is often not completed by a single cutting and stamping workshop. Many parts may also be interspersed with mechanical processing, heat treatment, surface treatment, etc. Cross workshop and cross department operation guidance is controlled by their corresponding process specifications. However, in different industries, especially when processing sheet metal components with low professional technical requirements and low complexity, a comprehensive process specification is often compiled to guide production.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque