In angulo oculi, decem annos CNC lathe operati sum et aliquid scientias machinationis et experientias in latibus CNC accumulavi. Ideas commutare cum colleagis meis volo. A causa frequentia replacionis parterum machinarum et conditionibus factoriae constituerunt, programmabamus, instrumentum inspectionem, debuggerem, et completionem machinarum parterum nobis in praeterito decem. In summario, operational skilles nostrae divisae sunt in sequentibus punctibus. (Autor/Li Neng)

Programming skills: due to the high precision requirements of our factory for processed products, the following factors need to be considered when programming:

1. Processing sequence of parts:

Drill first and then flatten the end (this is to prevent material shrinking during drilling);

First hard car, then fine car (this is to ensure the accuracy of the parts);

Primus procedere illos cum maioribus tolerantibus, et tunc processere illos cum minoribus tolerantibus (hoc assegurat, ut superficie parvuli tolerantibus granditudinis non scrutatur et prohibetur part is deformationem).

2. Elegite velocitatem rationalem, fluctum, et secere profunditatem basem super angustiam materiae:

1) Elegite fertilia carbon cum alta velocitate, alta fertilia velocitate, et magna profunditate cutae. Exemplo: 1Gr11, elegite S1600, F0.2, et profunditatem 2mm sequitur;

2) Elegite velocitatem minimam, fluctum minimam, et minimam profunditatem segregationis pro difficilis ligaminibus. Exemplo: GH4033, select S800, F0.08, and a cutting depth of 0.5mm;

3) Titanium ligamentum cum minima velocitate, alta fertilitate, et minima profunditate secendi debet. Exemplo Ti6 select a S400, F0.2, et profunditate 0.3mm sequitur. Procedentem quam partem quam exemplum est: materia K414 est, quae materia difficile est. Post multitudinem temptationibus, novissime quam S360, F0.1, et profunditatem 0.2 sequitur ad producendum partem qualificatam.

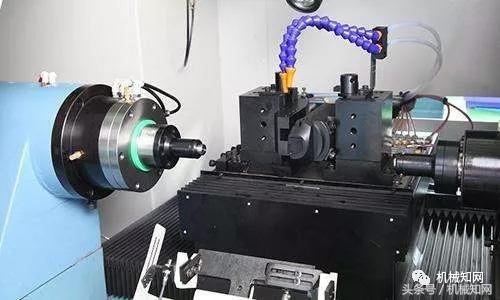

2,The knife alignment technique is divided into knife alignment instrument and direct knife alignment. Multae latus in fabrica nostra non habent instrumentum alignationem et rectum alignationem instrumentorum requirunt. Sequente techniques alignationis instrumentorum referunt ad alignationem instrumentorum directam.

Primo, selecta centrum summae dextrae partee quam punctum alignationis instrumenti et pone illud quam punctum nullum. Post instrumentum machinae revertitur ad originem, omne instrumentum, quod oportet esse, alignitur cum centro summae partee dextrae quam punctum nullum. Quando instrumentum ad faciem dextram intravit Z0 et cliccat super button mensurae. Valor compensation is instrumenti automaticamente recordabit valorem mensuram, indicans quia axis Z recte alignetur. Assis X est pro concitatione probationis, et cum instrumentum utilizat ad configurationem circuli exterius partis, intravit x20 ut mensuram valorem exterius circuli exterius partis adjustetur (sicut x 20mm). Clicca super button mensurae, et valorem compensationis automaticamente recordabit valorem mensuram. In hoc puncto, axis X etiam recte alignetur. Haec methodo alignationis instrumenti, etiam si instrumentum machinae extinguitum est, non convertetur valor alignationis post potestatem accedentem et restartem. Est adequat pro productione magna et longa tempora ex ea parte, in qua lathe non oportet redigere.

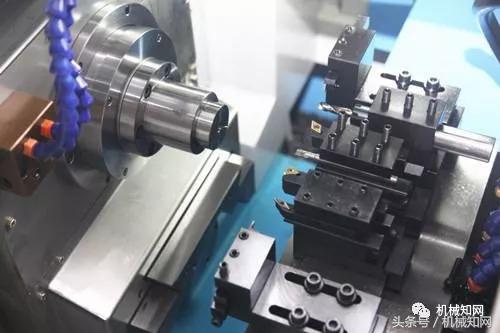

3, / Debugging skills: After programming and aligning the tool, the parts need to be tested and debugged. To prevent errors in the program and tool alignment, which may cause collision accidents, we should first perform empty stroke simulation machining. In the coordinate system of the machine tool, the tool should be shifted to the right by 2-3 times the total length of the part as a whole; Tad simulationem machinarum incipite. Post consummationem simulation is, confirmate quia programma et instrumentum alignmentum rectum sunt, et postea machinare partes. Post primum partem machinatum est, auto verificare et confirm are quia qualificata est, et postea inveni inspectorem dedicatum ut inspectatur. Solo post dedicatum inspectorem confirmat quia qualificata esse potest defectum perficere.

4 , After the first piece of trial cutting is completed, the processed parts need to be mass-produced. However, the qualification of the first piece does not mean that the entire batch of parts will be qualified, be cause during the processing, different processing materials will cause tool wear. Soft processing materials have less tool wear, while hard processing materials have faster tool wear. Therefore, during the processing, it is necessary to conduct frequent inspections and timely increase or decrease the tool compensation value to ensure the qualification of the parts.

Taking a certain part as an example, the processing material is K414, with a total processing length of 180mm. Due to the extremely hard material, the tool wear is very fast during processing. From the starting point to the end point, a slight deviation of 10-20mm will be generated due to tool wear. Therefore, we must manually add a slight deviation of 10-20mm in the program to ensure the qualification of the part.

In breve principum processionis primum machinae difficile est, extra materia de opera et tunc machina precisio aufert. Vibratio vita est in processione; Multae causae sunt evadere vibrationem causam de deformatione thermae dum opera fabricationis, quae potest causam excessimam cargam esse; Ut esset rationans inter instrumentum machinae et fabricationem, aut insufficientem rigiditatem instrumenti machinae, aut propter passivationem instrumentorum causam. Vibrationem per sequentibus metodes reddere possumus: Reduce lateralem fluctum et profunditatem machinarum, vide si clampio laboris secur est, cresce velocitatem instrumentorum, quod reddere potest resonantiam per minimum velocitatem. Additione, vide si necesse est substiture instrumentum novo.

5, Experientia inter instrumentos machinarum prohibere collisionem multo detrahit accuracionem instrumentorum machinarum, et impactus variatur pro diversis typis instrumentorum machinarum. Generale loquente, habet maior impactum super instrumentos machinarum cum infirmitate rigiditate. So for high precision CNC lathes, collisions must be absolutely eliminated. As long as the operator is careful and masters certain anti-collision methods, collisions can be completely prevented and avoided.

Prima causa collisionum:

Unus est error introitus diametri et longitudinis instrumenti succidentis;

Secundo, sunt errores in inpositione dimensionibus et alteris related geometric dimensions of the workpiece, as well as errors in the initial positioning of the workpiece;

Tres, systema operationis operationis instrumenti incorrecte constituetur, aut nullus punctus instrumenti machinae restituetur in processo machinae, resultant in changes. Collisions instrumentorum machinae in principio occurrunt during the rapid movement of the machine tool, and the hazards of such collisions are also the greatest, which should be absolutely avoided.

So operators should pay special attention to the initial stage of program execution and tool replacement. If the program is edited incorrectly or the diameter and length of the tool are entered incorrectly, collisions are likely to occur. At the end of the program, if the sequence of the retraction of the CNC axis is incorrect, collisions may also occurre.

Ut evaderet collisiones supra mentionatas, operator functiones facialibus suis utilizat quando instrumentum machinae operantur, observate si quid moventur abnormale, scintibus, sonibus abnormales, vibrationes, aut odores ardentes sunt. Si invenerit aliquid abnormal situatio, program statim cessare debet. Instrumenta machinae soluta est soluta soluta soluta solutio solutio solutio solutio solutione potest.

In breve, mastering the operation skills of CNC machines is a gradual process and cannot be achieved overnight. It is based on mastering the basic operation of machines tools, fundamental knowledge of mechanical processing, and basic programming knowledge. Opportiones CNC instrumentorum machinarum non fixae sunt, operatorem opus est imaginationem suam et manum operantiam in combination organic utilizat, quod est opera nova.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque