Dives experientia habemus in design et fabricatione parvulorum et precisiorum partibus metallis stampionis. We keep close communication with our customers and help them optimize the structure of their components from our perspective, resulting in excellent performance and manufacturability of stamped parts. Below, the editor of Yiwei Precision will introduce the process of customizing precision stamping parts.

We attach great importance to the early development work, and for each new product introduction, we will establish a project team to conduct special follow-up. For the development and manufacturing of Metal Stamping parts, we gather experienced engineers from the company's mold design and manufacturing, process engineering, etc. to produce detailed and rigorous DFM reports for product production.

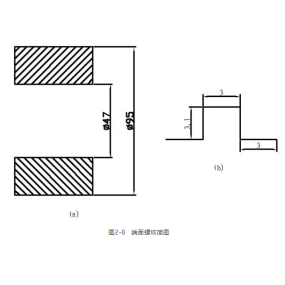

2. In terms of mold design, we have also accumulated rich experience in design and manufacturing. Winning's 3D design software is used to develop and design molds. We have a powerful knowledge database that collects many cutting-edge mold structures, and have the basic strength to develop various complex precision stamping parts. We use Yishengbai mold steel as the mold material, and well known industry standards such as Mismi standard parts, Master hot runner, and Saint Wanji hot runner for mold accessories. We use equipment such as Swiss Shamir slow wire and Makino electric spark to process mold parts, and conduct quality inspections of mold parts using equipment such as German Zeiss CMM and high-precision Rockwell hardness tester to ensure that the mold accuracy meets production and manufacturing requirements.

Postquam pater confirmavit exemplum qualificatum esse, cum productione massa procedemus. Maquinas punching alta velocitate importantes ad productionem pulsere utilimus, cum tempus punching 800-1200/minuta, multo meliora productionem effectivitatem et necessitatibus urgentis productionis clientes.

Zhejiang Yiwei Precision Co., Ltd. is a manufacturer of precision metal and plastic parts. Our core technical team has been focusing on precision metal stamping and plastic molding for over 30 years. We also have over 20000 square meters of our own factory and hundreds of precision punching machines, automation equipment, and processing machinery. Son birkaç yıldır, ekibimiz büyük precision mold teknolojisini topladı ve ürün kalitesinin basisini küresel müşterilerin ihtiyaçlarına uygulamaya başladı.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque