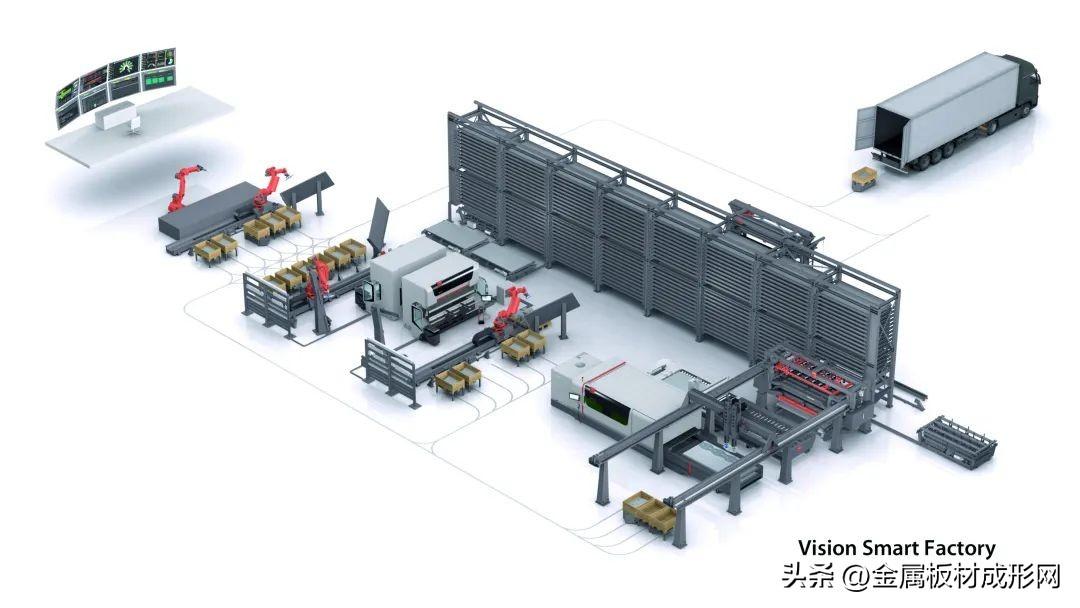

Chassis et cabinet lapides metallos processus est processus fabricationis platearum metallorum in voluntatem formam per diversas metodes fabricationis, includientes sectiones, bending, conculcationes ad faciem trationem, ecclesiam et multos alteros gradus. Usually, the process from chassis and cabinet sheet metal to metal products starts with drawing, and after the drawing is completed, various parts are made through the sheet metal manufacturing process.

translators

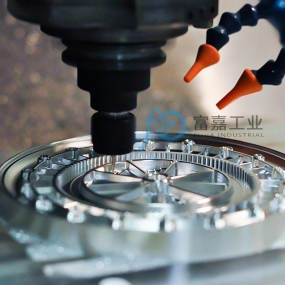

Laser cutting is the preferred method for cutting chassis and cabinet boards. It is a very fast and precise cutting method that is not limited by molds. As shown in Figure 1.5mm, the board is cut flat, smooth and free of burns.

CNC turret punch press

Stamping is another method of cutting holes in the sheet metal industry, which uses a metal punch to impact the sheet metal and punch holes. It is suitable for large-scale production. When encountering regular shapes such as circular holes and multiple holes, CNC turret punching machines can quickly achieve them using mold stamping.

Bending

Pro complexitate bending, hoc potest esse caliginem difficiliorem in fabricatione metallorum pro chassis et fabricatione metallorum lapides cabinetis, et ingenieres familiari sunt proprietatibus bending metallorum.

benedictionis

The welding process is based on the production nature, drawings, and technical requirements of the product, combined with existing conditions, to weld the cut and bent sheet metal parts in a box.

Spray coating (surface treatment)

The welded box body is transferred to the spraying workshop for powder coating after trial assembly. Pulver coating is the process of applying electrostatic powder coating on a workpiece. Under the action of static electricity, the powder is uniformly adsorbed on the surface of the workpiece, and then baked at high temperature to form the final coat.

The surface of the product after spraying is dustproof and water proof, and its adhesion, corrosion resistance, aging resistance, and other aspects are superior to the spray painting process, making it suitable for various hard external environments. Quando non sunt necessitates speciales, metodo superficie preferitus est.

Imprimere

Aliquid chassis et cabinetes directo transferentur ad ecclesiam post sprayionem, sed et alii sunt qui requirant imprenta logos aut parabolas et ad imprentam cubiculum transferentur.

UV flatbed printers are a dark horse among industrial printers. Compared to traditional screen printing processes, their functions are very powerful: they do not require typesetting, can adapt to printing of different sizes, can be molded in one go, have beautiful and clear patterns, are sun resistant and waterproof, and most importantly, are environmentally friendly and odorless.

CNC glue dispensibile

Compared with traditional manual adhesive strips, CNC glue dispensing has firm adhesion, smooth and beautiful surface, seamless one-time molding, strong adhesion, good elasticity, water proof and dustproof.

assembling

Final step in productione cassis cabineti est ecclesia. All the sheets metal parts are ready, just congregate them together.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque