To understand the processing methods of industrial aluminum profiles, the first thing to understand is whether to change the processing method of aluminum profile structure or the processing method of industrial aluminum profile surface processing technology. Generally speaking, CNC machine tools can easily change the mechanism of aluminum profiles, whether it is milling, drilling, tapping, stamping, bending and other processes can achieve deep processing.

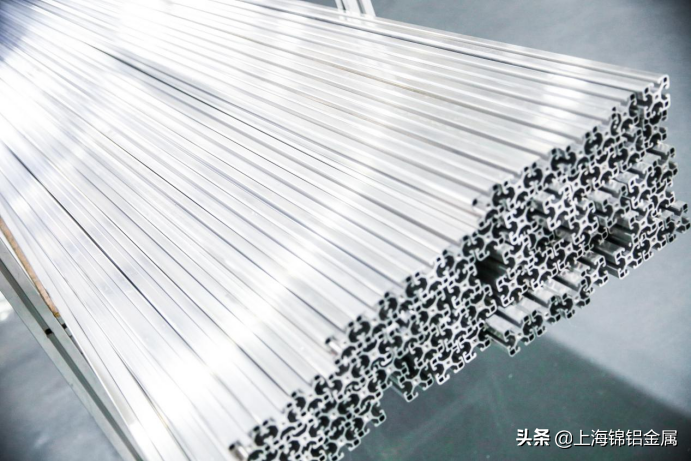

The surface treatment and processing methods for industrial aluminum profiles of Jinlu are as follows:

First, the sandblasting process: the process of cleaning and roughening metal surfaces using the impact of high speed sand flow. Haec metodo certa gradus munditiae et diversae angustiae super superficiem artificis opus possit, proprietates mecanicas superficie opus, et sic elevare resistentiam fatigae opus.

Sequente est polisterium: metodo processionis, qua methodos mechanicales, chemicales aut electrochemicales utilizat, ut redderet superficiem crudelitatem parterum aluminium automobili, ut superficiem splendorem et splendorem acciperet. Procedus pulsationis prima in pulsationem mechanicam, polysationem chemicam et pulsationem electrolyticam dividitur.

Next is wire drawing: Metal wire drawing is the manufacturing process of repetitively scraping aluminum plates in lines with sandpaper. Paintura catela dividetur in drawingem lineae rectae, drawingem lineae rotae, drawingem lineae spirale et drawingem lineae.

Finally, anodizing treatment: the surface of industrial aluminum profiles is treated with silver white oxidation, which is elegant, beautiful and corrosion resistant.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole