As is well known, stainless steel metal processing refers to the cutting, bending, grooving, and other processing of stainless steel and other metal sheets. Whether in daily life or industrial applications, we often see the presence of stainless steel processing products, so its application fields are very wide. Quando multi amici familiari sunt fabricationes metallicorum metallicorum sterilis, multo de fluxo procedentis eius sciunt. Scisne fluxum metallorum metallorum pellicularum inmaculatum? Below, the editor of Aima Technology Co., Ltd. will introduce you:

Planning of Stainless Steel Sheet Metal Processing Drawings ->; Laser processing or (CNC stamping) ->; Bending ->; Forming ->; Pulver electrostatis coating or (pictura liquida) ->; Packaging and shipping

1. Planning of stainless steel sheet metal processing drawings

In early stage of stainless steel metal processionis, necesse est intellegere potentibus communibus.Departatio ingenierii praecepta agentibus delegat. Postquam scientibus agentibus eos audierunt, potuerunt sign are et mittere ad atrium.

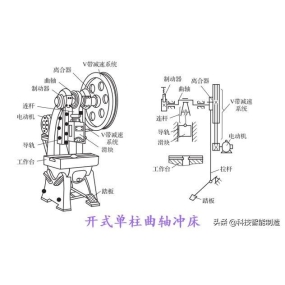

2. Laser processing or (CNC stamping)

Laser processing has no tool limitations, a flat cross-section, and is suitable for processing irregular workpieces, but it takes longer to process small workpieces. Placing a workbench next to CNC and laser is beneficial for placing the sheet metal on the machine for processing, reducing the workload of lifting the board.

3. Bending

When processing and bending stainless steel metal, it is necessary to confirm the direction and standard of the bending with a sample. If there is excess or missing material, it should be adjusted in a timely manner. After the sample is confirmed, large-scale production can be carried out. Then, when replacing the mold and checking the work during production, it is necessary to start from scratch. Inspectione qualitatis facite in partes metallis lapides sterilis processae, exemplum et testate standardes partes metallis lapides, et tunc inspecte eas visually. Pro produktos non conformentes, reverte eas in fornacium et implete inspectionem report.

4. Welding Forming

Convex punctus in uniforme connexio cum platea antequam connexio connexio in singulis punctibus calefactionis conditus est.

5. Pulvere electrostatic coating or (pictura liquida)

The surface treatment of stainless sheet metal processing generally includes phosphating film, electroplating multicolored zinc, chromate, baking paint, oxidation, etc. Phosphating film is generally used for cold-rolled plates and electrolytic plates, and its main function is to coat a protective film on the material surface to prevent oxidation. Selection of specific surface treatment methods depends on the customer's requirements. ●

6. Packaging and shipping

Prius congregationem fabricationis metallicis metallicis sterilibus protectibus ligaminibus orijinalis in spraying procedentibus dispersi sunt ut certem quod rupae intrinsecus partes non sunt ferentes pinguine aut pulvere. In to to processo digitabus portantur ut non adhererent pulverem ad fabricationem. Si invenerunt debris aut pulverem super fabricationem, munda est antequam ingrediatur procedum pacificis.

In summario, fluxus metallis calicis calicis est. However, due to the different structures of sheet metal parts, their process flow may also vary. Procedentia autem productionis omnes adhuc facta situatio sequuntur.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque