Numerical control machine tools provide automatic machining methods for high-precision and high-efficiency product production, especially for the production of complex surface parts

1 , Basic concepts

1. Digital control

Name

2. Numerical Control Technology

Technology of using numerical quantities and characters to issue commands and achieve automatic control has become the fundamental technology for manufacturing to achieve automation, flexibility, and integrated production

3. Numerical Control System

Control system using digital control technology

4. Computer Numerical Control System

Numerical Control System with Computer as the Core

5. CNC machine tools

Programma praeprogramata secundum opus processionis, quae mitt instruktiones digitas informationes ab systema controllis ut processat opus

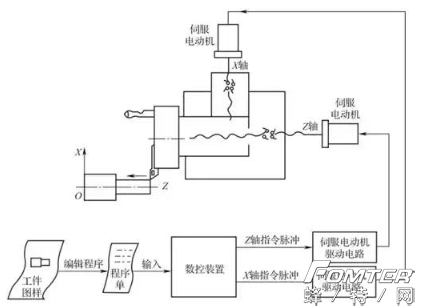

2,The working process of CNC machine tools

1. Develop a program

2. Intra apparatum CNC

3. Processing and calculation

4. Issue instructions

5. Drive orderly actions and operations

6. Realize the relative motion between the cutting tool and the workpiece

3,Characteristics of CNC machine tools

1. Strong adaptability and good flexibility in processing parts

2. Exalta procedentia precisa et stabila qualitate produktorum

3. Strong comprehensive functions and high production efficiency

4. High degree of automation reduces labor intensity for workers

5. Reducit productiones costas et beneficia ekonomica

6. Digital production and improved management level

4,Types of commonly used CNC machine tools

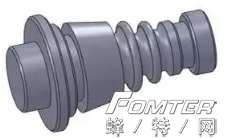

1. CNC lathe

Name Motor eius principium est rotatio artis laboris relative to the tool, and cutting energy is provided by the workpiece rather than the tool

2. Turning center

Equipped with a power driven tool device and the ability to position the workpiece spindle around its axis. Equipped with a cultro magazine that can automatically change cultros. Capabilitate finis facibus, radialis et eccentric conversationis, milling, drilling, and boring machining of end faces, radial and eccentric turning, milling, drilling, and boring

3. CNC milling machine

Instrumentos numericas de controllo machinae, quæ milling ut methodo processionis ususque rotationem cuttorum in principibus moventur, et motionem pecoris aut (et) excutitorum militum in motionem fertilis.

4. Machining center

Equipped with a tool magazine and automatic tool exchange device. spindle normale est struktura horizontal a aut verticala et habet duas aut plures modos machinationis

5. CNC grinding machine

Uter instrumenta grinding ut superficiem opus pulseres. CNC grinders plurima rotae velocitatis rotae rotationis rotationum rotationum pro manipulatione faciunt, dum alios alteros instrumentos grindentium, sicut oleum, cincturam harenam, et libera abrasia pro manipulatione

6. CNC drilling machine

Mainly use drill bits to machine holes on workpieces. Rotatio biti drilli principis motus est, et motus axiale bit drilli motus fertilis est

7. CNC EDM instrumentum machinae formationis

Uter modo electricae discharge machinationis ad faciendum speluncam, corporibus, cavernis et superficies. Principulus eius opus est duos electrodes diversorum polaritium ut faciat phenomena discharge in liquido insulatione, materiales auferre

8. CNC wire cutting machine tool

Machina electric a discharge machina quae metalla quam instrumentum electrodam utilizat ut opera agentur. Principulus eius operatus est aeque quam discharge electricae CNC instrumentorum machinarum formationis

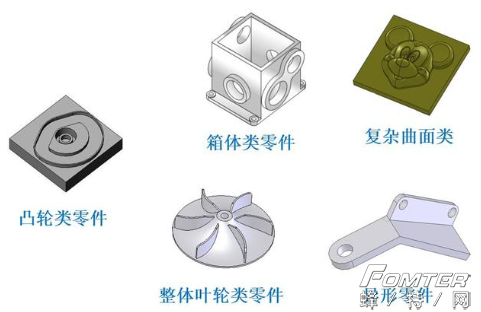

5,Application of commonly used CNC machine tools

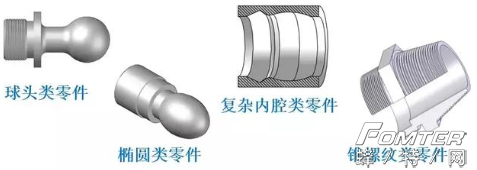

1. Application of CNC lathe

Processing rotary parts with particularly complex contour shapes or difficult to control dimensions, rotary parts with high precision requirements, and rotary parts with special threads

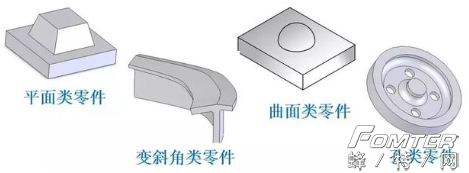

2. Application of CNC milling machine

Processentes partibus contour duodedimensionalis aut tresdimensionalis, sicut contour planar, contour inclinatus, et contour curvatus; Possibile est etiam procedere partes typorum rupum, sicut fluctus, expansiones, contradictiones, metientes, absorbentes et ferentes

3. Application of machining centers

Suitable for processing complex, multi process, high-precision parts that require multiple cutting tools and can only be processed after multiple clamping and adjustments

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque