When designing sheet metal shells, there are some key points that need to be noted to ensure that the design product meets functional requirements and has a beautiful appearance. Sequentes sunt plures aspecti, qui notari sunt in prozessu fabricationis pellicularum metallorum:

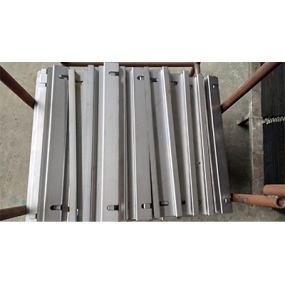

1. Material selection: Choose suitable sheet metal materials based on product requirements, such as stainless steel, carbon steel, aluminum alloy, etc. Considere factores such as the mechanical properties of the material, surface treatment requirements, and cost.

2. Determine thickness: Select the appropriate sheet metal thickness based on the load and strength requirements that the product can resist. Materiae metallici fabricatae aut debiles effecti sunt vitae produkti et servitutis.

3. Determine dimensionem et formam: Designe the size and shape of the sheet metal according to the actual needs of the product. Considere factores such as the appearance, structural characteristics, and usage environment of the product.

Productor of chassis and cabinet

4. Structural design: In sheet metal shell design, structural design is a very important part.

5. Quola et interfaces installationis reservata sunt: When designing sheet metal shells, sufficient space and position need to be reserved for product installation and interfaces. Exemplo, interfaces potentiae, interfaces signalis, holas dissipationis calore, etc. omnes in design considerandum sunt.

6. Design verification: After completing the design, it is necessary to verify the rationality and feasibility of the design. Instrumentos analisationis simulationis aut produktio exemplorum factum ad verificationem utilizatur.

7. Consider processing technology: Based on the selected materials and dimensions, choose the appropriate processing technology, such as cutting, bending, drilling, welding, etc. Different techniques processionis influentiam habebunt super formam et granditudinem lapideorum metallorum, et seleccio necesse esse in situatione actual.

8. Trepta superficie: Elegite adequatum metodo superficie tractionis secundum necessitates produktorum, quasi spraying, electroplating, oxidation etc. Surface treatment can improve the corrosion resistance and aesthetics of products.

In summary, when designing sheet metal shells, it is necessary to comprehensively consider materials, dimensions, shapes, processing techniques, surface treatment, structural design, and verification to ensure that the designed product meets functional requirements and has a beautiful appearance.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque