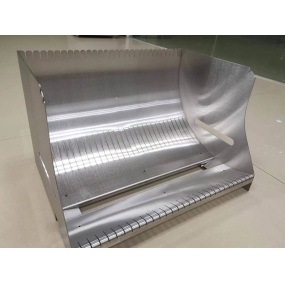

Quomodo costam fabricationis metallorum calculari est? They are all product prices=material costs, processing fees, surface finishing fees, various taxes, and profits. Preces specific dependt on the specific drawings. How to use the hardware processing fee of Jiuding Machinery as an example to illustrate, classified according to different processing equipment, stamping mold processing parts are called hardware processing; Digital stamping, laser, and Sheet Metal Processing products are called sheet metal processing. To understand the cost of sheet metal processing, it is necessary to know the processing technology algorithms and prices of sheet metal and hardware. In addition, hardware processing also needs to consider mold costs. Taking a single set of process molds hardware as an example to calculate processing costs:

The cost composition of hardware generally consists of mold cost, material cost, transportation cost, value-added tax, 15-20% management fee, etc. Exemplo plateas electrolytic as accipientes.

1 , Mold Costa mold a dependit on its processing size, processing quantity, precision requirements, etc. Generally, the processing cost of a mold is much higher than the material cost. 2 , Material cost refers to the maximum material cost required by the drawing=material volume * material density * material loss rate during processing, which also needs to consider the material unit price.

Costa processionis per singulos proceduras pro processione produktorum est. List the main process cost components:

1. The cost composition of mold cutting=equipment depreciation sharing cost, labor cost, auxiliary materials, equipment depreciation amortization: equipment depreciation is calculated over 2 years, 12 months per year, and 22 days and 8 hours per month. Exemplo, depreciatio 200000 molds per horam=20 * 10000/2/12/22/8=47.4 yuan/hour labor costa: unusquisque mold duos operatores et unus mold installer ut placet. Praeda simila est operator is. Medium salarium mensis pro singula persona est 5400 yuan per 22 dies et 8 horas opus per mensem, quod significat horatis pretium 5400 * 3/22/8=93 yuan/hour

Potentia materiae auxiliaria: Omnia pulssa pulssa est munera electrica circa 2000 yuan per mensem, calculata est 22 dies et 8 horas per mensem. Costa est 11,4 yuan/hour, quod est 2000/22/8

3. Composition of surface treatment spraying cost: Spraying cost:=powder cost, labor cost, auxiliary material cost, equipment depreciation, powder cost calculated by square meter, powder unit price is 25-60 yuan/kg, and 4-5 square meters can be sprayed per kilogram of powder. Ut dicit, pulvere costa est circa 6-12 yuan/quadrata metro: 6000 yuan/persona per mensem pro sprayi, 22 dies per mensem 8 horas, et circa 30 metros quadraticos per horam. Labor cost a=6000/22/8/30=1.14 yuan/square Metro Auxiliari materiae costa: Costa solution is pre-treatment, primus, currans furnacis et ceteris materiae auxiliaris est circa 50000 yuan, et 30 metros per horam per 8 horas 22 dies in mense sprayit. Potentia materiae auxiliaria est 5000/22/8/30=9,47 yuan/square metrus, et totum procento sprayionis est circa 10,6 yuan/square metrus, quod non necessarium est protectionem loci.

4,Packaging fee

Costa packaginga materia packaging et labor constituit. Due differences in product size and packaging methods, prices vary, ranging from approximately 20-30 yuan/cubic meter. Additionally, transportation management fees are charged based on operational costs and are typically allocated to the product.

6,Management expenses

Expendita administracionis in duas partes divisa sunt: leasing fabricae aquae et electricae, et expendita financiae; Administrationes expensas normale cogitant circa 10% ex omni venditate pretio.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque