According to the shape of the component or product, Metal Stamping involves various processes, each of which is different. Haec procedura conpleta et meticulousa design parterum et produktorum in industriis, sicut aerospace, produktios consumatores, automotivas, aviatione, electronica, cibum et bibendum etc. Usually it's not possible to manufacture a component using a single metal stamping method, since each process involves creating a specific design.

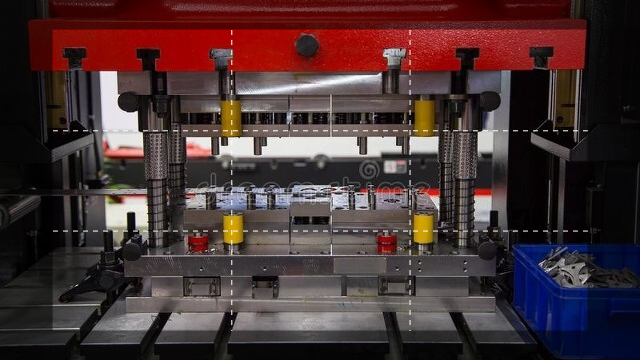

Multi stamping techniques involve processes such as extrusion, stretching, and rib pressing. Each technology involves a mixture of various processes to achieve the required components. Omnes haec metodes in temperatura cubiculi exercitus sunt, normale minima aut nulla calore. Stamping hardware is a typical cold forming manufacturing process that involves the use of several tools and equipment, such as stamping machines (punch presses), molds, etc., to form complex shapes and appearances.

Pro hoc, aliquid ex populariis procedentibus armaturae quae ex fabricatoribus utilibus sunt discutabimus.

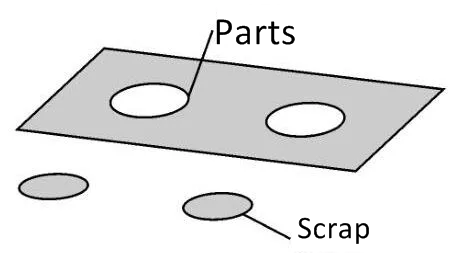

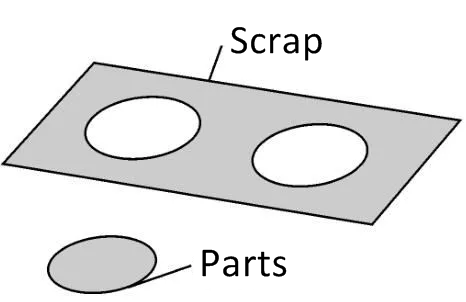

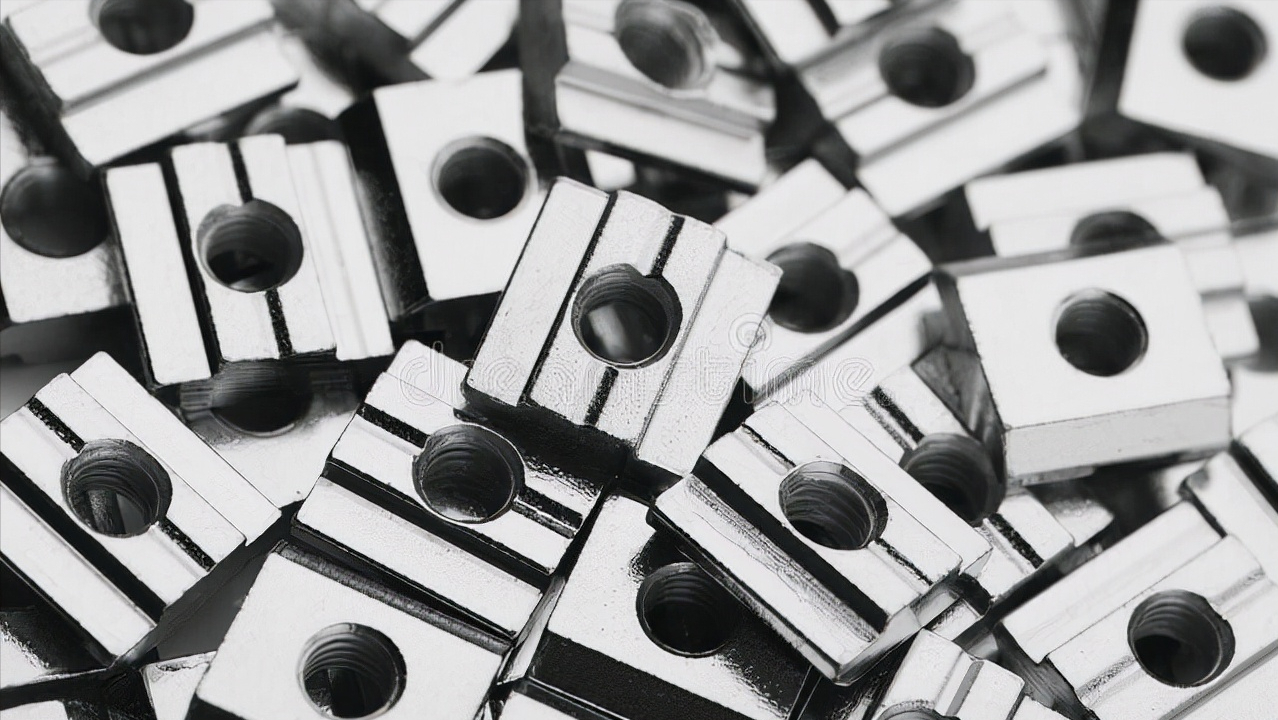

Punching method is a common metal stamping process. Pellicula metalla in uno loco fixa est, aut precisa, in tabulis operis. Using different tools and machines, create a hole on a metal plate and create a series of different hollow areas on the metal plate. Punching is a bit different because after punching on a metal plate, the perforated part is removed and no longer used.

To ensure that the metal plate is not deformed, punching must be a continuous process. Area circum punching precisa designata est. Maquina in hoc processo metallico stampionis ex alto ferro carbon facta est et perfecto conservetur ita ut non sit passivatio aut regiones passivation is, quae potest causare deformationem formae metallici.

There is not much difference between the cutting method and punching - however, a big difference is that perforated boards will not be thrown away. The punched sheet is the final component. Multae companiae metallici stampionis semper ante faciendum alios in projecto stampionis faciunt. Post consummationem commutationis materiae, fabricator procedet cum alteris stagibus imprimisi hardware, sicut extrusion et bending.

Material cutting essentially involves manufacturing sheet metal - usually on small or medium-sized metal sheets cut from large pieces. Quando ad productionem massae est, hoc est particular utilis, quam facile est et ducit ad summam qualitatem et precisionem basem cutum.

However, in some cases, metallic plates may contain unwanted edges or flares. Haec est interrogatio communa; However, sharp ends and burns will eventually be removed through several processes, such as thermal deburring, manual deburring, and/or vibration methods.

Quando ad pulserum metallos, alii fabricatores etiam proceduram extensionis utilizat. Haec methodo basically involvet fixere duos terminos plateae metalli (contra terminos). Proximus gradus est plagam metallem in fuscino intersectione positum. Through a powerful stamping process, the mold produces a punch that pushs the sheet metal on the machine. This helps to develop the cross-sectional shape of the machine, fully deforming the metal plate to meet the requirements.

Metodo extensionis etiam dividetur in duos alteros prosessos, appellato extensionem profundum et diligentem extensionem. Haec procedura simila sunt ut profunditatem necessitatem facerent in plate a metalla. Exemplo, dum dilucetur, radius plateae principis metallis semper correspondet ad profunditatem extensionis, quod significat aequalem esse.

In altera parte, profunda extensione basically calicio formatur secere in plateis metallis ut diversos produktos formatur. Inter profundum processum drawing is, totum radium plateae metalli multo minor est compared to the depth to be carried out.

Metodo extrusion is in stampionis metallis est procedus usus ex fabricatoribus ut producentur et componentes in formis extrudentibus. Metodo squeezing involvet '; Closed molle; Technica fabricationis. In hoc case, the metal plate is used as a whole or squeezed in parts. Haec processus duos mollos independentes constituit, cuius positiones gradually inter se ad duos terminos platei metalli, formantes formam coini.

Unus de maximo beneficiis methodos extrussionis est quod multo effectum est in manu diversorum partes metallorum et produktorum cum diversis tolerancis quantitatis. It is also a relatively direct technology that can quickly and reliably produce deformations (usually permanent) on products. Basically, component or product is highly resistant to deep physical wear and strong impacts.

Lingua technica cuta est perfecto diferenta a cutting and punching methods. Quomodo id mittere? Bene, lingua cutting involves a unique metal stamping process that doesn't require removing any metal parts from the sheet metal. Punching and mold process is set to create a deep seam on the metal surface. Est purpose of doing so is to avoid generating any metal waste, such as metal plugs that need to be disposed or removed in the post-processing stage.

Unus ex principibus causis qua fabricatores linguam secant est ut hoc processus facit diversas disegnationes unicas et personalizatas et formas per diversa typa metallorum. Exemplo, saepe utilitur componentes et partes creare quae ad aplicationes, quales apertura, venta, etiqueta etc.

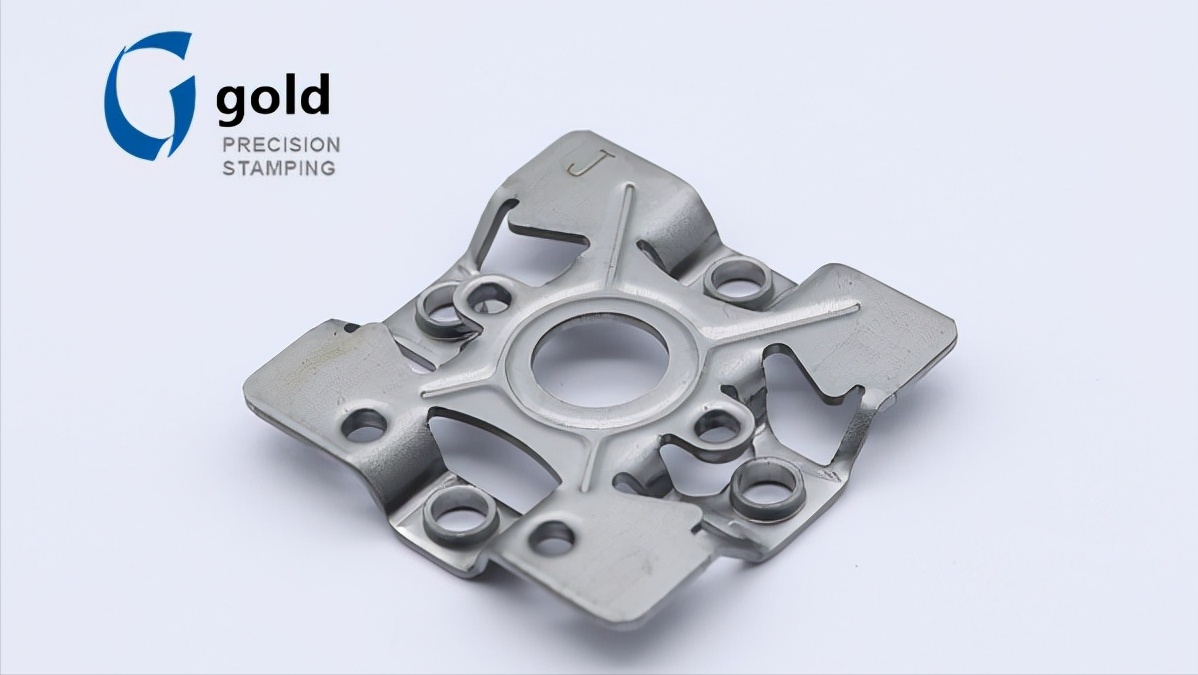

Metodo reinforcementiae platearum metallorum altera technica unica est, quam supra facies elevatis in specific areas of the metal plate design. Reinforcing bars can be created using two different methods - through mold sets or machines. The reinforcement method is mainly used to create parts and components for various applications, depending on the complexity and form of the required design. Exemplo, quidam ex optimis exemplis operantium componentium corrugatorum includent operimentum metallos, capita motorum, lapides ostium, lapides pelliculae et cetera.

Tecnica reinforcementiae in superficie metallis diversis utilizatur, tamen, popularius tipus metallis in hoc processo est aluminium. Hoc prima est, quia hoc metallum facilem est processi. In addition, this material is durable and light weight, both of which contribute to making the reinforcement process more efficient and efficient.

Factores importantes cognoscere in medio stampionis metallorum

Quando ad fabricationem metallorum est, tecnologia metallorum stampionis utilissima est. Ut hoc factum est, omnis processus super complexitatem tecnologiae loquitur. Exemplo, celeris et directis procedentibus, quales material drop or punching saepe referuntur ad primum nivellum omnis projecti. Haec procedura aliis procedentibus consent ut productum perfectum formarent.

On the other hand, complex stamping procedures such as deep drawing, language cutting, extrusion, and/or rib pressing are mainly used to create complex designs that don't require processing throughout their entire production cycle.

In summario, metalla stamping is an extremely important and future oriented process that is crucial for many industries. This process is used to manufacture daily consumer products, as well as larger components and parts for manufacturing vehicles and other things.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque