Metodo est aeque simplex atque illud, sed valor magnus est. Clave est si dederis illum an non!

Hoc est solum unum de modis, multae modi sunt, quas Jun Ge te postea docebit.

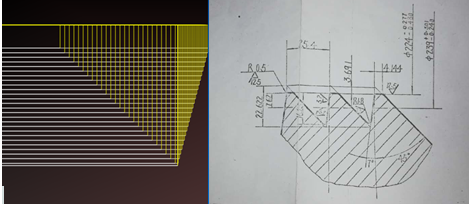

Diagramma litora instrumentorum inverti est metodo ingenieriae, et typus litora instrumentorum postea determinabit quomodo programmam scribere.

Exemplo, diagramma graduum graduum graduum serratum subter monstrata est, cum angulis dentium diversis in utraque latere.

Exemplo, diagramma gressus instrumentorum per virgam TR subter, cum instrumentis protulit ex utraque latere

Articulum hodie de programmatione macro s ad T formas

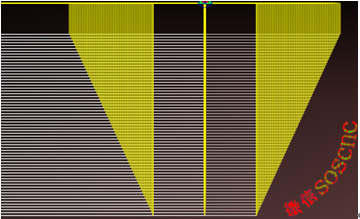

Ut monstravit in diagramma superioris litoris cultris: Transportum ligatum, tres cultros per layer, id est, medium primum, et tunc levis et dextras cultros a utraque latere posuerunt

Magnifica diagramma via cultris sicut in sequente figura monstrata est:

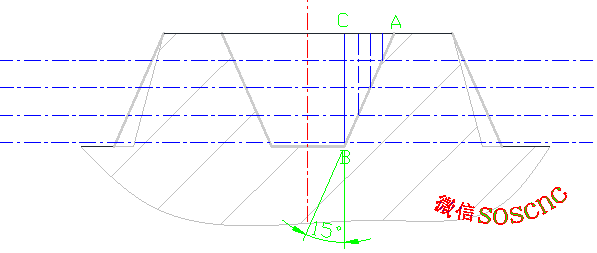

In hoc modum omnes intuitivus vident, quod cum profunda profunda sequitur profunda, instrumentum propter lineam AB movere debet, ut instrumentum proeliatum egredietur cum profilo fertilis.

Aliis sermonibus inter altitudinem cultris X et magnitudinem in directo Z est, qui satisficat legem Pythagoream, id est TAN15=AC/BC

So we can deduce: AC=TAN15 * BC

Haec relatio nimis grava est. In subsequente programmatione, quoniam profunditate BC mutata est, AC etiam secundum hunc relationem mutat, sic processant formam tr typus thread profile.

So the contour shape of Tr doesn't necessarily mean that Tr threads can be processed satisfactorily.

Quia et instrumenta succidere cogitari sunt in processione.

Because each Tr type thread has a specific dent size.

Exemplo, latitudinem blandiae elegita est 2mm (ad sinistram et dextram pinctum blandiae minimam est quam latitudinem basis dentum)

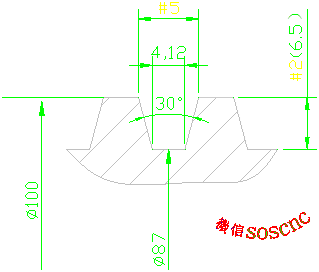

Exemplo, TR100 * 12 thread externi, dimensiones relevantes sunt sicut:

I can set any number of variables as shown in the above figure

#2 represents tooth height, which is the depth of the incision

#5 represents the total width of the dents, which is the size of the thread profile we need to process

#5= 4.12+2*TAN[15]*#2

quia et vasa sequitur latitudinem habet, latitudinem speluncis alveolari debet esse:

Tooth base width+2 x slope width - tool width.

So the final # 5=4.12+2 * TAN [15] * # 2-2 (including the tool width)

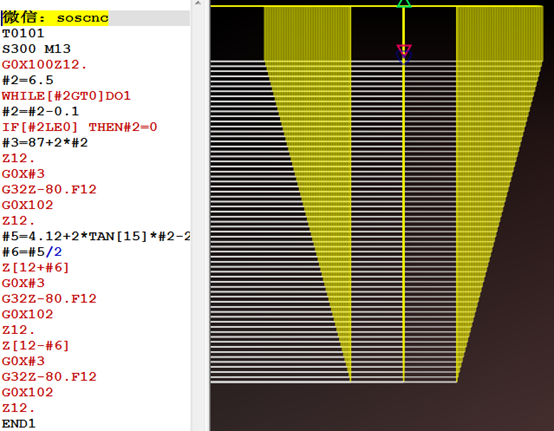

Okay, that's all for the analysis.Just go straight to the program.

T0101

S300 M13

G0X100Z12. (Quickly move to the starting point of the thread)

#2=6.5 (initial assignment of tooth height)

WHILE [# 2GT0] DO1

#2=# 2-0.1 (cutting amount, 0.1 per layer of vehicle, one-sided value)

IF[#2LE0] THEN#2=0

#3=87+2 * # 2 (Since # 3 is assigned a value of 6.5 and the first cut is made at the larger diameter of the thread, the smaller diameter plus the height of both teeth equals the larger diameter. When the value of # 2 changes, it means that the larger diameter also changes, thus achieving layered cutting)

Z12. (Z12 est referentia positionis, et principes lapides sinistris et dextris consequentibus in programma secundum omnes basentur Z12)

G0X # 3 (downward cutting in direction X)

G32Z-80.F12 (thread cutting)

G0X102 (retraction)

Z12.

#5=4.12+2 * TAN [15] * # 2-2

#6=# 5/2 (since both sides borrow the knife, divide # 5 by 2 and divide equally)

Z [12+# 6] (Primus cultrum de dextera possit, adde # 6 quia culter ad dexteram movendum est)

G0X#3

G32Z-80.F12

G0X102

Z12.

Z [12- # 6] (Primus cultrum a sinistra possit, subtract # 6 quoniam instrumentum ad sinistram movere debet)

G0X#3

G32Z-80.F12

G0X102

Z12.

END1

G0X200.

Z200.

M30

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque