CNC (Computer Numerical Control) est CNC Machining technology controlled by a computer, which can achieve high-precision and high-efficiency machining processes. The principle and technology of CNC machining are as follows:

1. Numerical control programming: First, it is necessary to write machining programs using specialized numerical control software. Programma machinationis includet informationes, quales via machinationis, parametros, percursum instrumentorum, etc.

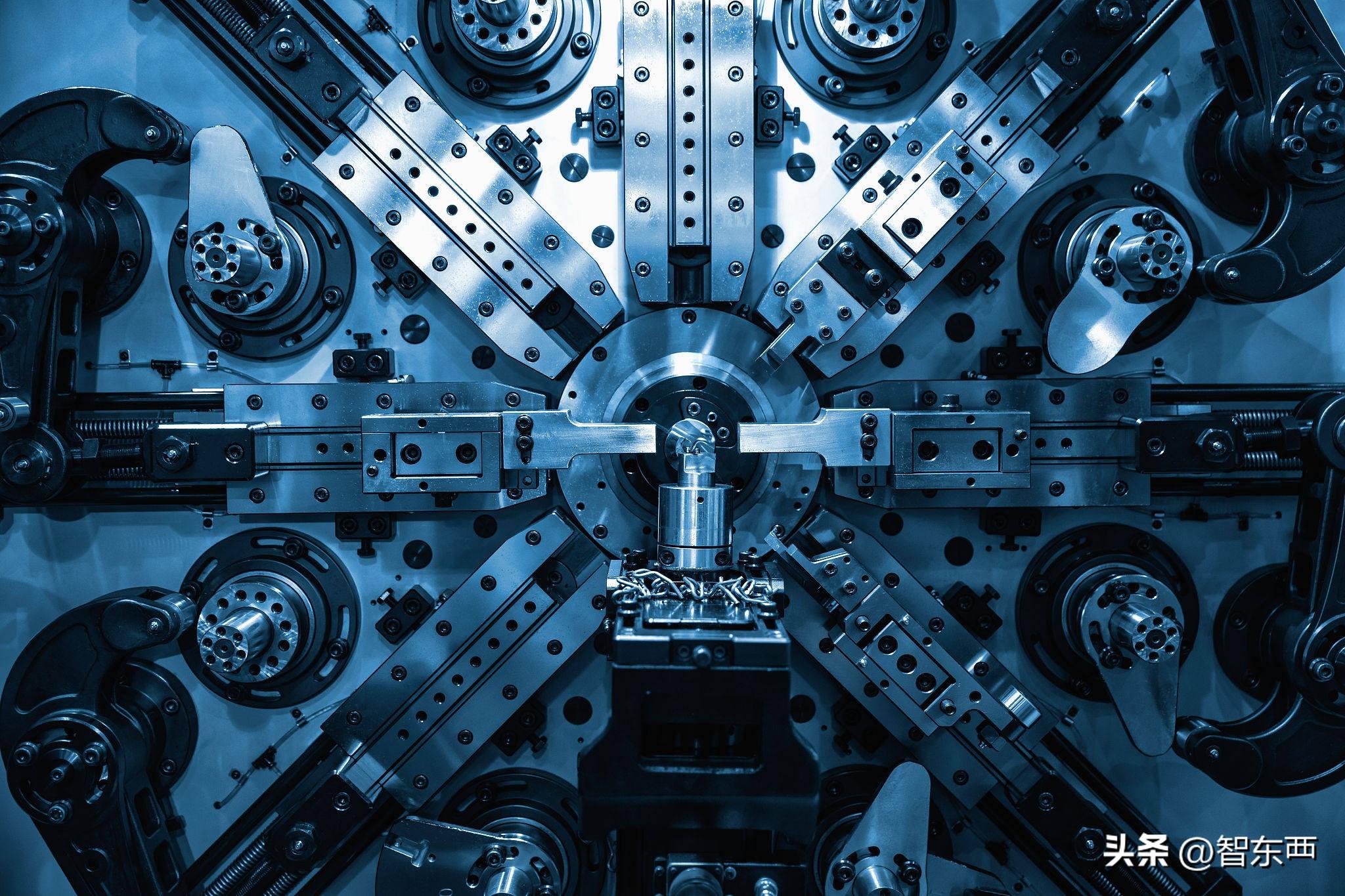

2. Instrumenta machinae: Programma machinae praescripta in systemam controlli instrumenti CNC cargata est. The control system controls various power components on the machine tool, such as the spindle, feed axis, and cutting tools, through the computer based on program instructions to achieve machining operations.

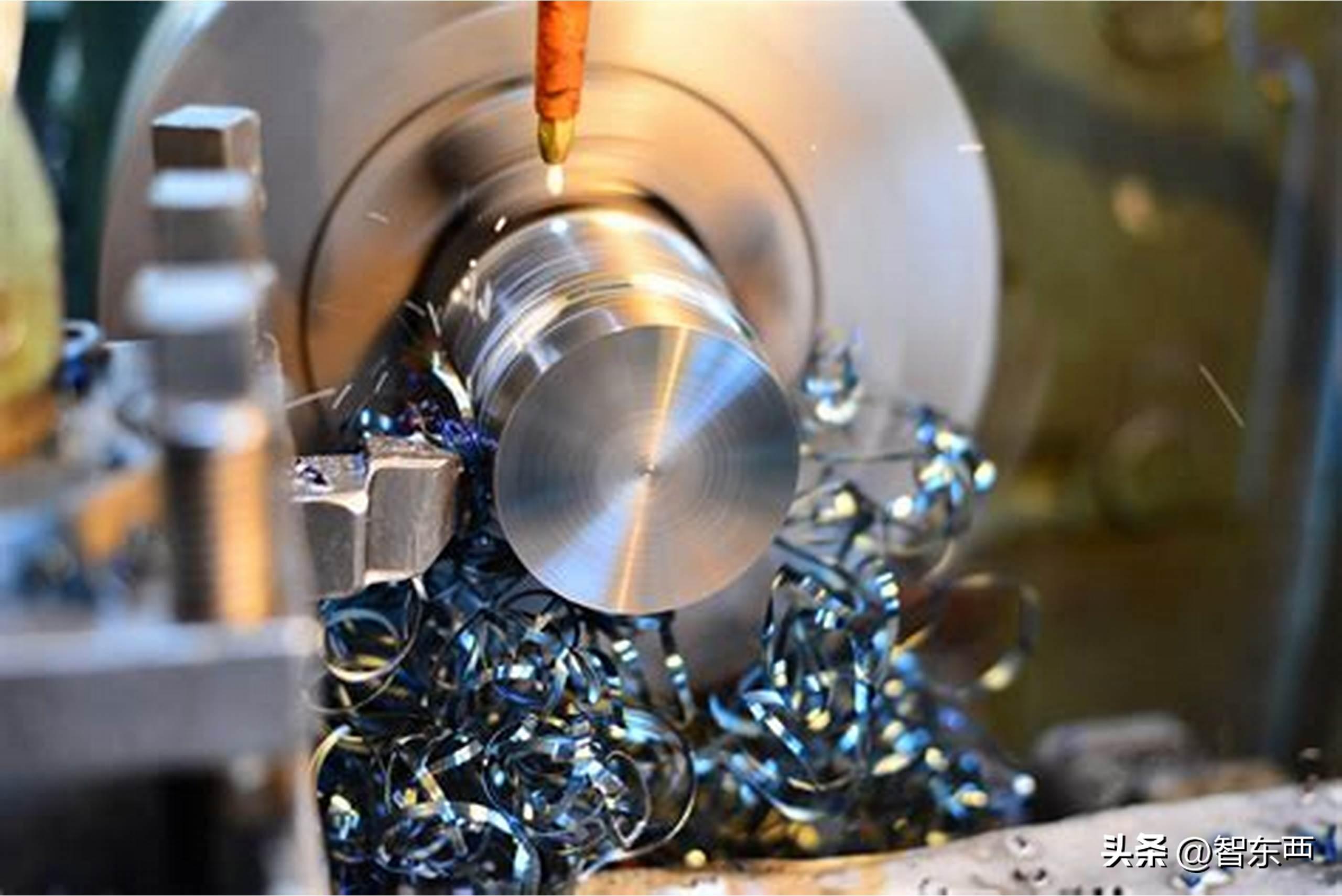

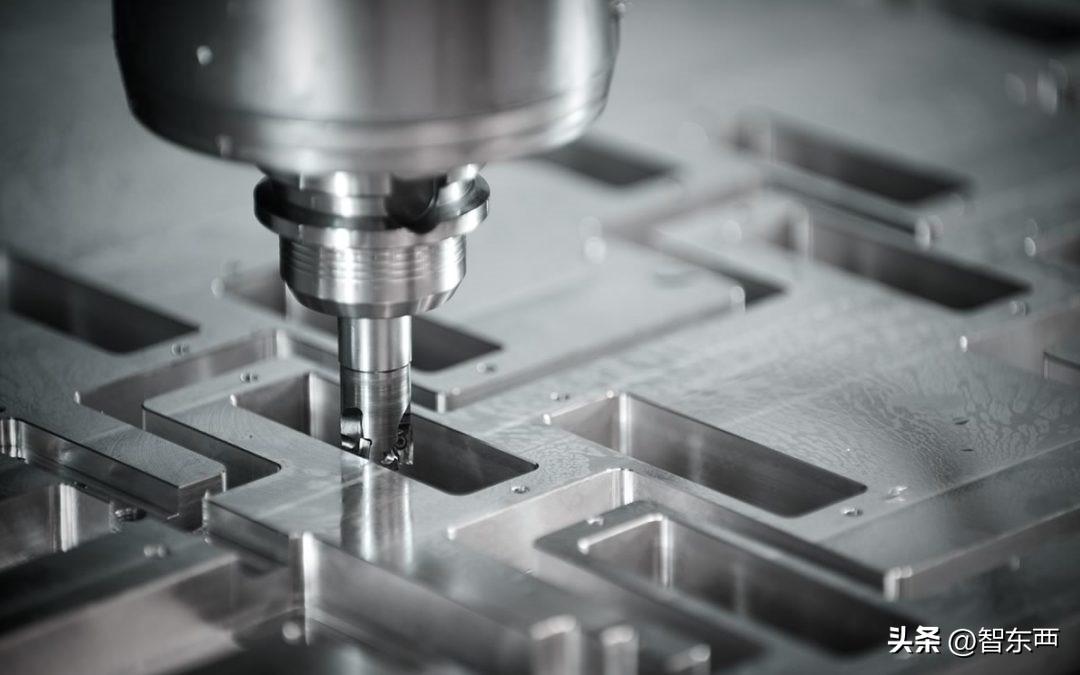

3. Machining process: During the machining process, the machine tool processes according to the path and cutting parameters specified in the machining program. Systema control controla motionem et velocitatem instrumenti secundum instruktiones programmae, graduam materiae raw in voluntatem opus fabricationis sequitur.

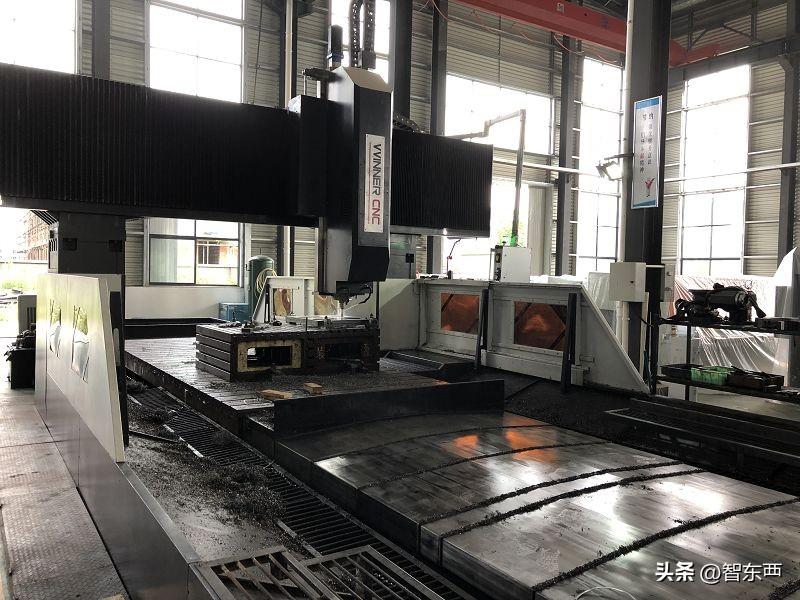

4. Automation control: CNC machining can achieve automation control. Through pre-written machining programs, machine tools can automatically perform machining operations, reduce manual intervention, and improve production efficiency and machining accuracy.

Concerni numerum axorum, libertatem motionis et machinationis instrumenti CNC representat. Instrumentos CNC communes habent numeros axorum varios, sicut 3-axis, 4-axis, 5-axis, etc. Quanto plus asses sunt, maximus gradus libertatis instrumenti machinae in spatio, facientes operationes machinae complexas.

-3-axis machine tools: typically have three axes, X, Y, and Z, representing horizontal, vertical and longitudinal motion, respectively. Plastis et simplis triadimensional processionis adequatur.

-4-axis instrumentum machinae: Addentem axim rotationem super superficiem axis 3, saepe circum axis Z rotantur. It can achieve rotational machining of works pieces.

-5-axis machine tool: Adding a tilt axis on the top of the 4-axis, it can achieve tilted machining of work pieces. Potere facies complex as processare, sicut partes automotivas, partes aeroplanes etc.

Quanto plus asses sunt, plus fortior machina capabilitatem instrumenti machinae, quæ potest plus complexa et precisa operationes machinae attingere. However, at the same time, the increase in the number of axes will also increase the complexity and cost of the machine tool. Seleccio adequato numero axorum determinabitur based on specific processing requirements and budget.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque